Non-uniform nucleation coating treatment method of a soft magnetic composite material with high saturation magnetic flux density

A soft magnetic composite material, non-uniform nucleation technology, applied in the fields of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of unsuitable industrial production, high cost, complex preparation process, etc. Comprehensive magnetic properties, high saturation magnetization, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

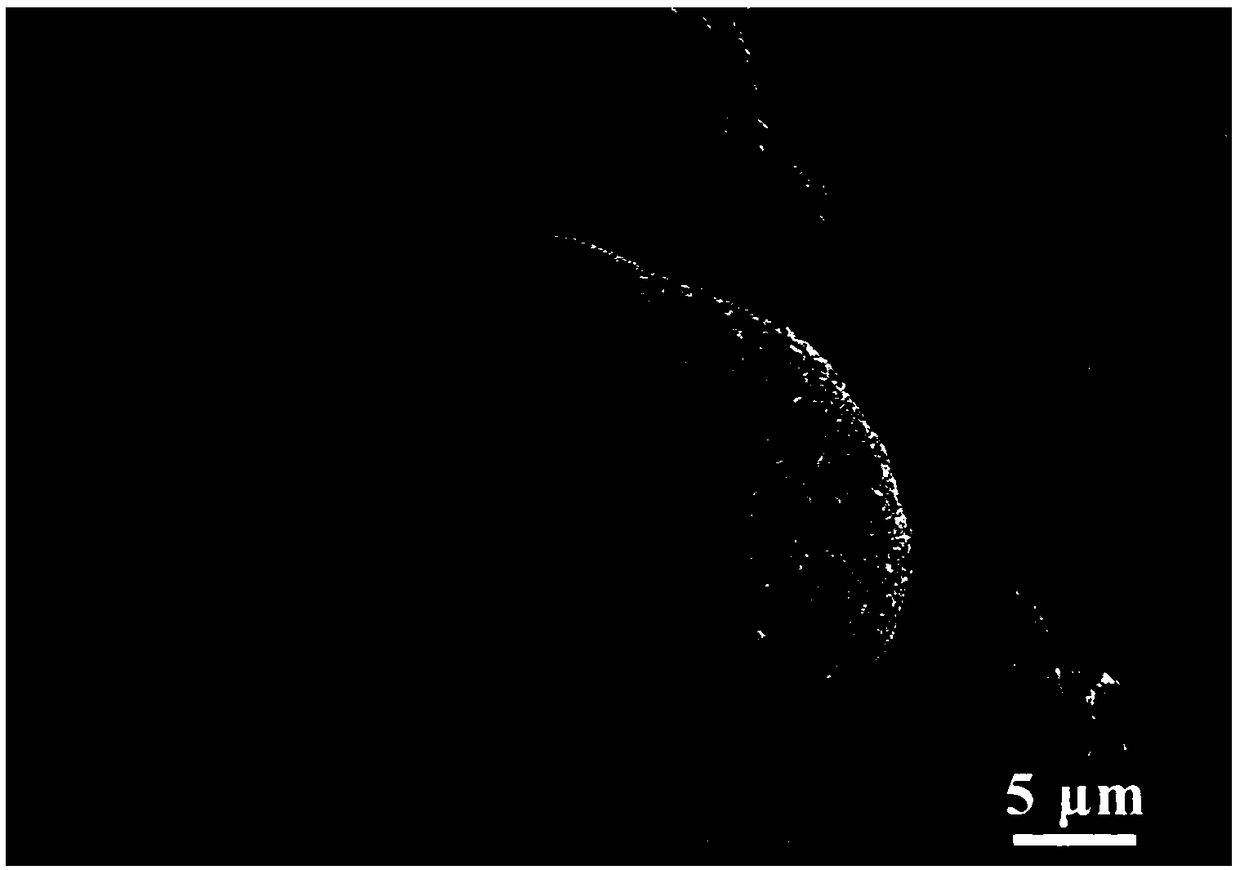

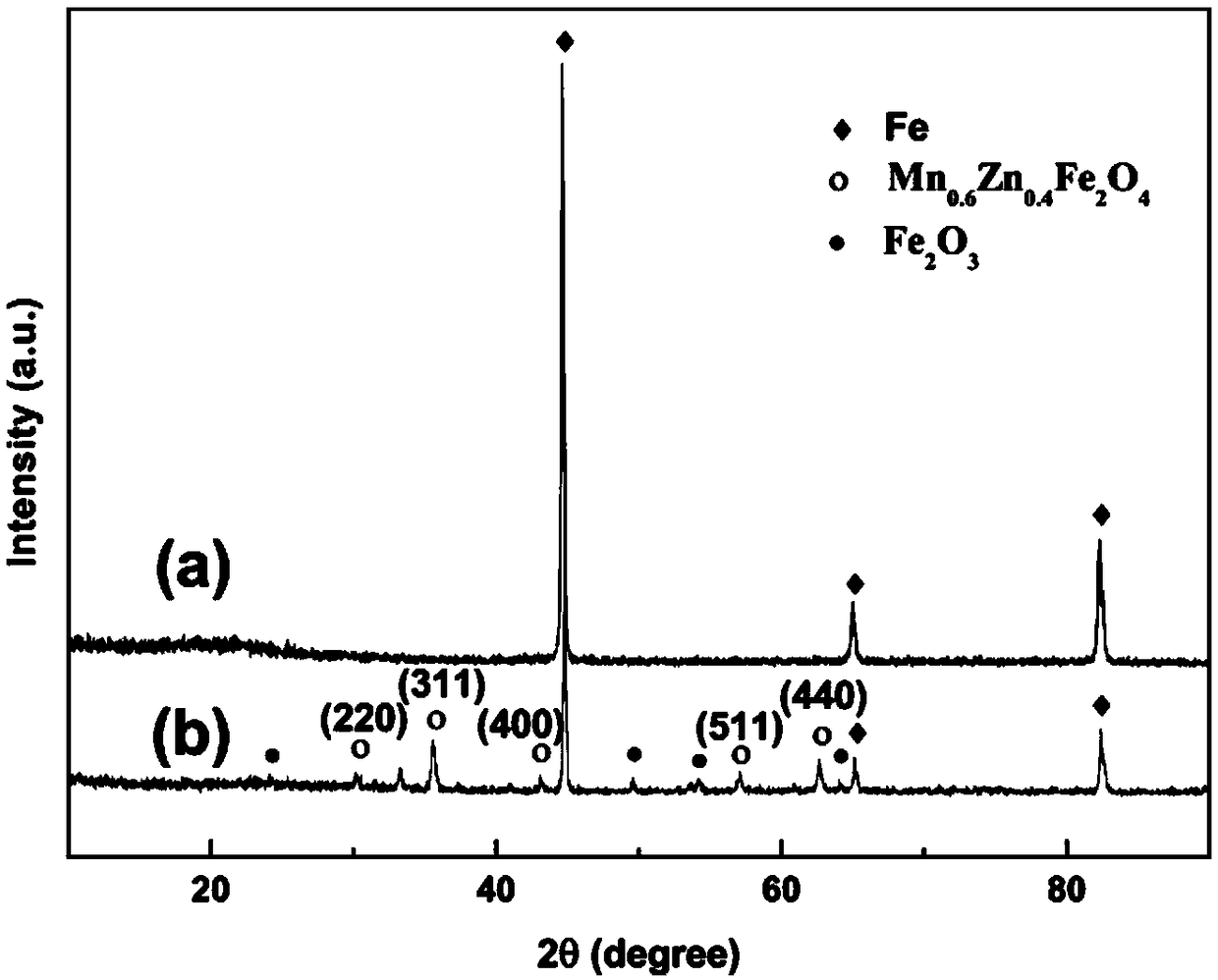

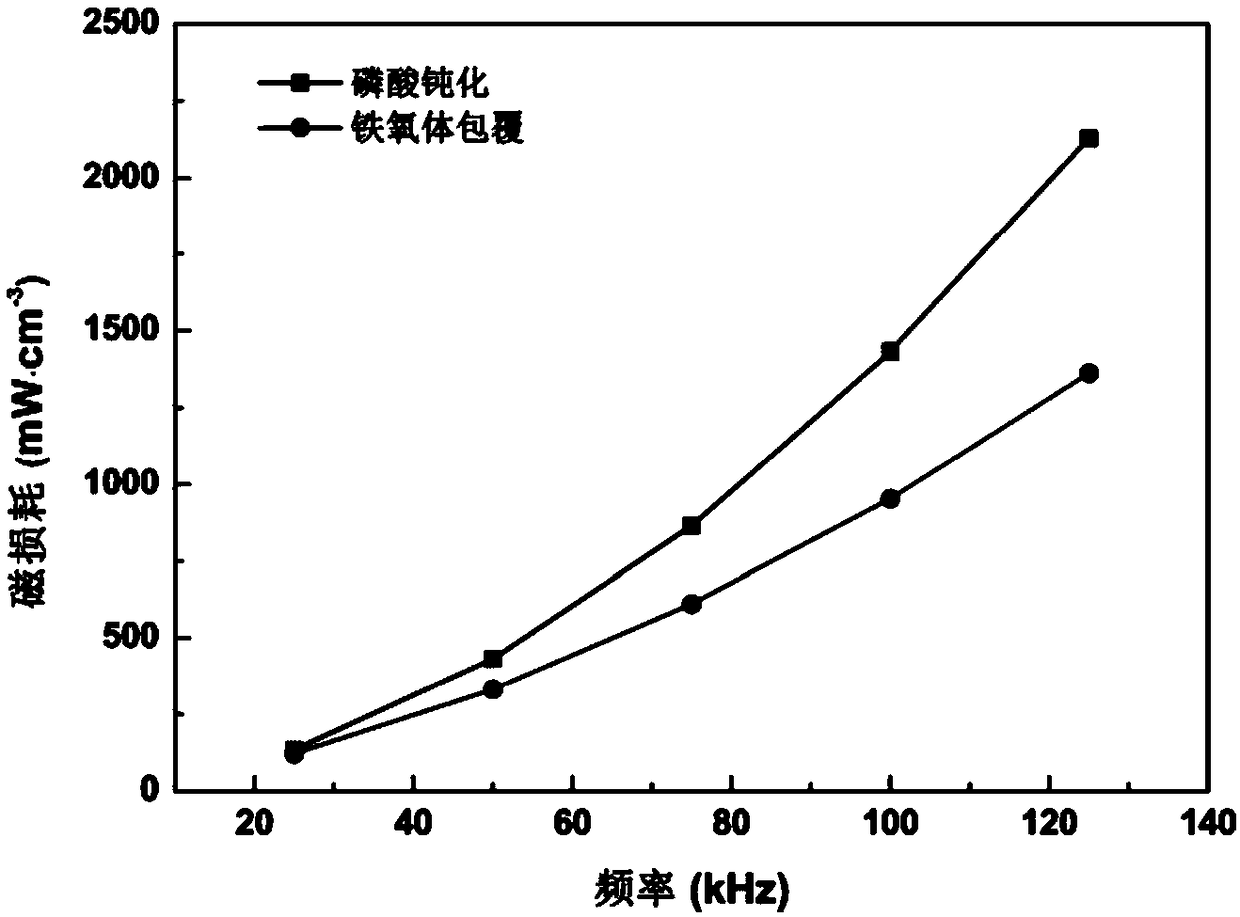

[0024] Take 15g of iron powder (ie metal magnetic powder), in which the particle size is -200~+300 mesh iron powder accounts for 60% of the total mass, -300~+400 mesh iron powder accounts for 30% of the total mass, and the iron powder above 400 mesh accounts for 10% of the total mass. Press iron nitrate, manganese nitrate and zinc nitrate according to Mn 0.6 Zn 0.4 Fe 2 O 4 Dissolve in 50mL deionized water to prepare a metal salt solution, adjust the pH of the metal salt solution to 4 with a buffer solution prepared with acetic acid and sodium acetate, add the magnetic powder with a good ratio to the metal salt solution, and stir at a constant speed to make The metal magnetic powder and the salt solution are fully mixed, and the stirring is continued for 20 minutes, and the mixture is allowed to stand at room temperature for 3 hours, then filtered and dried to obtain the metal magnetic powder coated with the ferrite precursor. The coated metal magnetic powder was calcined at 50...

Embodiment 2

[0031] Take 20g of iron-nickel powder, in which the magnetic powder with particle size of -200~+300 mesh accounts for 50% of the total mass, the magnetic powder with particle size of -300~+400 mesh accounts for 40% of the total mass, and the magnetic powder above 400 mesh accounts for 10% of the total mass. Mix iron nitrate, manganese nitrate, and zinc nitrate into Mn 0.8 Zn 0.2 Fe 2 O 4 Dissolve in 90 mL of deionized water to prepare a metal salt solution, adjust the pH of the metal salt solution to 6 with a buffer solution prepared by acetic acid and sodium acetate, add the well-proportioned magnetic powder to the metal salt solution, and stir at a constant speed to make the metal magnetic powder and The salt solution was mixed thoroughly, stirring was continued for 30 minutes, and then allowed to stand at room temperature for 7 hours, then filtered and dried to obtain metal magnetic powder coated with ferrite precursor. The coated metal magnetic powder was calcined at 600° C....

Embodiment 3

[0037] Take 30g sendust powder, in which the magnetic powder with particle size of -200~+300 mesh accounts for 70% of the total mass, the magnetic powder with particle size of -300~+400 mesh accounts for 25% of the total mass, and the magnetic powder above 400 mesh accounts for 5% of the total mass. Mix iron nitrate, manganese nitrate, and zinc nitrate into Mn 0.5 Zn 0.5 Fe 2 O 4 Dissolve in 30mL deionized water to prepare a metal salt solution, adjust the pH of the metal salt solution to 3 with a buffer solution prepared by acetic acid and sodium acetate, add the well-proportioned magnetic powder to the metal salt solution, and stir at a constant speed to make the metal magnetic powder and The salt solution was thoroughly mixed, and the stirring was continued for 40 minutes, and then allowed to stand at room temperature for 5 hours, then filtered and dried to obtain the ferrite precursor coated metal magnetic powder. The coated metal magnetic powder was calcined at 400° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com