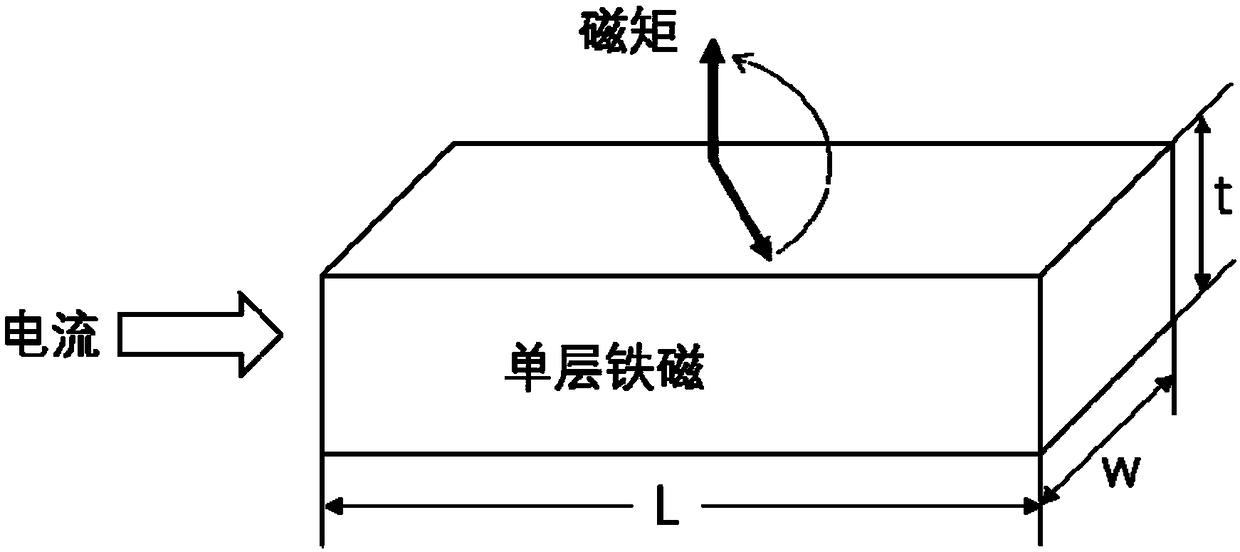

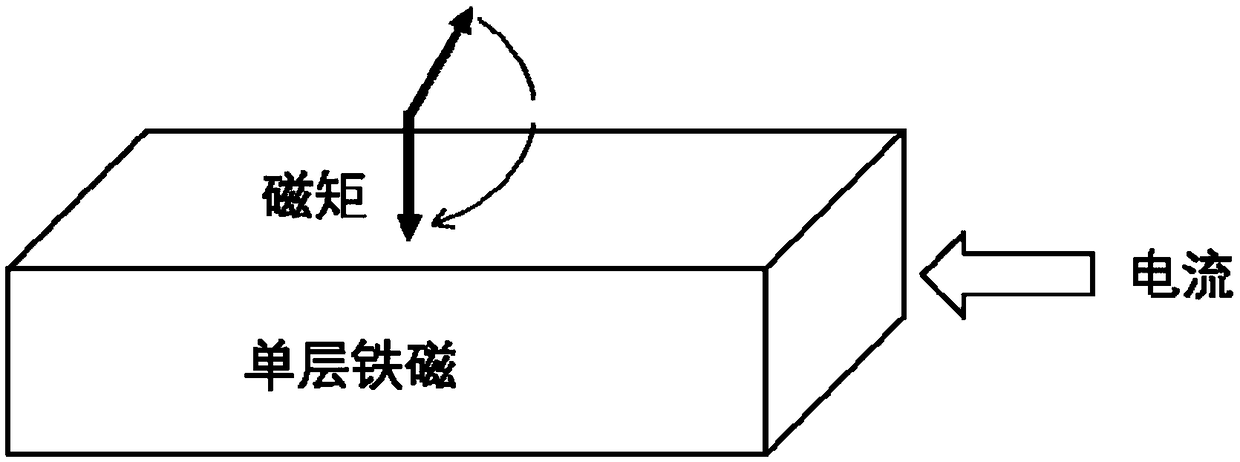

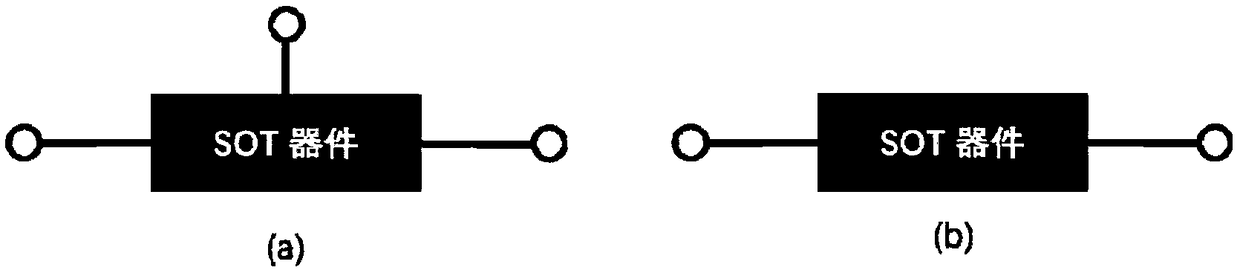

Single-layer ferromagnetic materials with current-driven magnetic moment flipping and their applications

A ferromagnetic material, current-driven technology, applied in the direction of material selection, magnetic field-controlled resistors, static memory, etc., can solve the problems of unfavorable device thermal stability, increase the complexity of device manufacturing process, etc., and achieve simplified architecture and manufacturing The effect of process, high thermal stability, great cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] like Figure 4 As shown, an embodiment of using the present invention to manipulate the magnetic moment of a single-layer ferromagnetic layer and detect the state of the magnetic moment, the single-layer ferromagnetic layer is prepared into the shape of a Hall bar as shown in the figure by using micro-nano processing technology. 201, 202 serve as two electrodes for applying current, and 203, 204 serve as two electrodes for measuring voltage. Since ferromagnetic materials have anomalous Hall effect, and the anomalous Hall resistance R H is proportional to the magnetic moment m in the normal direction of the film, that is, R H ∝m, so by measuring the abnormal Hall resistance value between electrodes 203 and 204, the direction of the magnetic moment of the ferromagnetic layer can be known. First, apply an auxiliary magnetic field along the direction from 201 to 202, and then apply a writing current I between the electrodes 201 and 202 W , the current can be positive or ...

Embodiment 2

[0034] In this embodiment, the present invention is used to construct the storage unit of the MRAM, that is, the magnetic tunnel junction. Image 6 A schematic diagram of the structure of this magnetic tunnel junction is given, from bottom to top there are 301 magnetic storage layer, 302 intermediate layer, 303 magnetic reference layer. 301 is a functional layer implementing the technology of the present invention, so the magnetic layer 301 should have a strong spin-orbit coupling effect. 302 The middle layer is oxide or non-magnetic metal. The 303 magnetic reference layer can use the same ferromagnetic material as that of the 301 layer, or can use a different ferromagnetic material. Image 6 A schematic diagram of the operation of writing data using the technology of the present invention is also given, that is, a write current is applied in the 301 layer, and the magnetic moment of the 301 layer is reversed to a specific direction by using the spin torque effect of the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com