Olive-shaped ternary material precursor, a preparation method and an application thereof

A ternary material, olive-shaped technology, applied in the field of olive-shaped ternary material precursor and its preparation, to achieve low cost and reduce surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

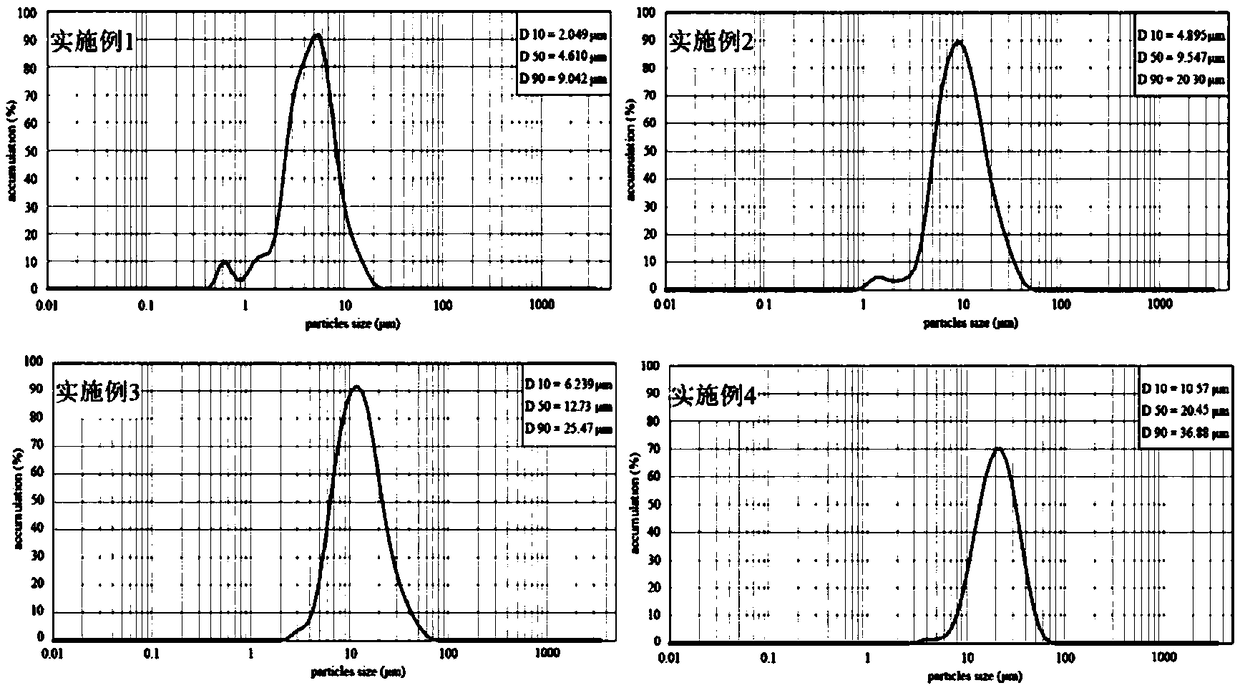

Embodiment 1

[0045] A method for preparing an olive-shaped ternary material precursor in an embodiment of the present invention, comprising:

[0046] Weigh biuret, Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 50% aqueous solution raw material, in addition, assuming that all Ni, Co, and Mn metal elements are converted into carbonate precursors, continue to weigh polyethylene glycol PEG accounting for 3% of the theoretical carbonate precursor mass, and add the above five Mix and dissolve the raw materials with deionized water, control the concentration of the solution to 1mol / L, then transfer the solution to a hydrothermal reactor and heat it to 200°C for reaction, keep the reaction time for 15h, and cool the hydrothermal reaction naturally after the hydrothermal reaction is completed. kettle to room temperature, filter, wash, dry, and grind the resulting precipitate to obtain the nickel-cobalt-manganese ternary carbonate precursor.

[0047] After mixing and grinding the ...

Embodiment 2

[0049] A method for preparing an olive-shaped ternary material precursor in an embodiment of the present invention, comprising:

[0050] Weigh carbaamide, NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O raw material, in addition, assuming that Ni, Co, and Mn metal elements are all converted into carbonate precursors, continue to weigh polyethylene glycol PEG accounting for 8% of the theoretical carbonate precursor mass, and the five raw materials weighed above Mix and dissolve with deionized water, control the solution concentration to 1mol / L, then transfer the solution to a hydrothermal reactor and heat to 160°C for reaction, keep the reaction time for 5h, and cool the hydrothermal reactor naturally to At room temperature, filter, wash, dry, and grind the resulting precipitate to obtain the nickel-cobalt-manganese ternary carbonate precursor;

[0051] After mixing and grinding the nickel-cobalt-manganese ternary carbonate precursor obtained in Example 2 and lithium hyd...

Embodiment 3

[0053] A method for preparing an olive-shaped ternary material precursor in an embodiment of the present invention, comprising:

[0054] Weigh biuret, Ni(Ac) respectively according to the molar ratio of biuret, nickel, cobalt and manganese as 20:5:2:3 2 4H 2 O, Co(Ac) 2 4H 2 O and Mn(Ac) 2 4H 2 O raw material, in addition, assuming that Ni, Co, and Mn metal elements are all converted into carbonate precursors, continue to weigh polyvinylpyrrolidone PVP accounting for 3% of the theoretical carbonate precursor mass, and use the five raw materials weighed above Deionized water is mixed and dissolved, and the total concentration of nickel, cobalt, and manganese metal ions is controlled to 0.6mol / L at the same time. Then, the fully dissolved mixed solution is transferred to a hydrothermal reaction kettle, and the reaction is carried out at 220°C. The reaction time is 16 hours. After the hydrothermal reaction is completed, the hydrothermal kettle is naturally cooled to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com