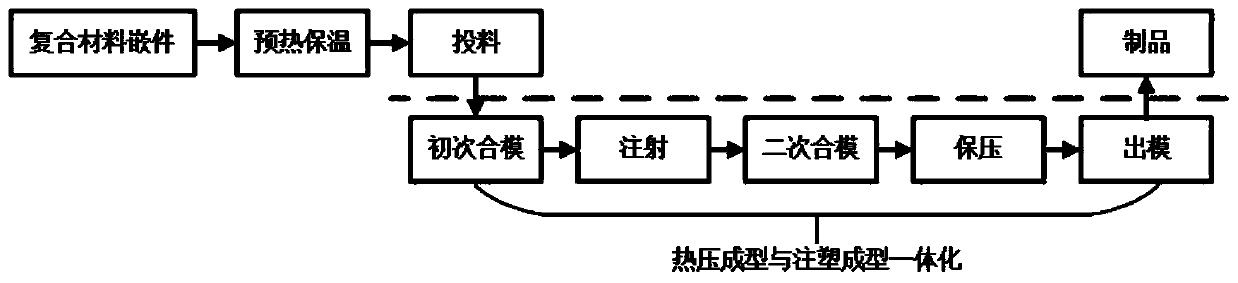

A method for integrally forming a thermoplastic composite structure on a resin plastic part

A thermoplastic and thermoplastic resin technology, applied in the direction of coating, etc., can solve the problems of limited application range, harsh combination conditions, low production efficiency, etc., achieve high design freedom characteristics, shorten the forming cycle and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

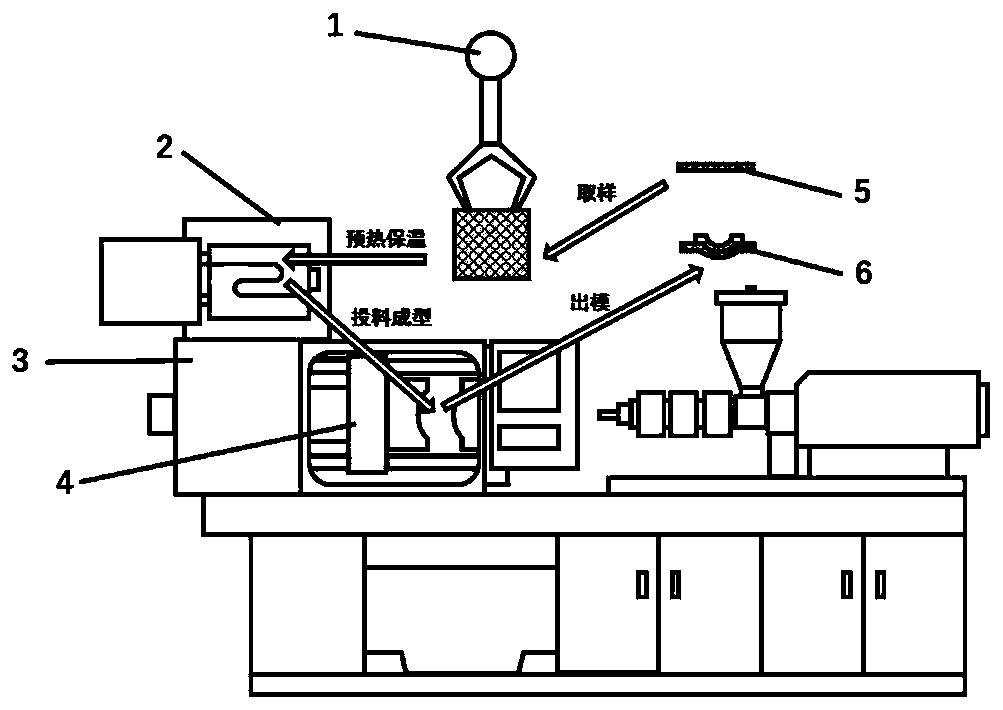

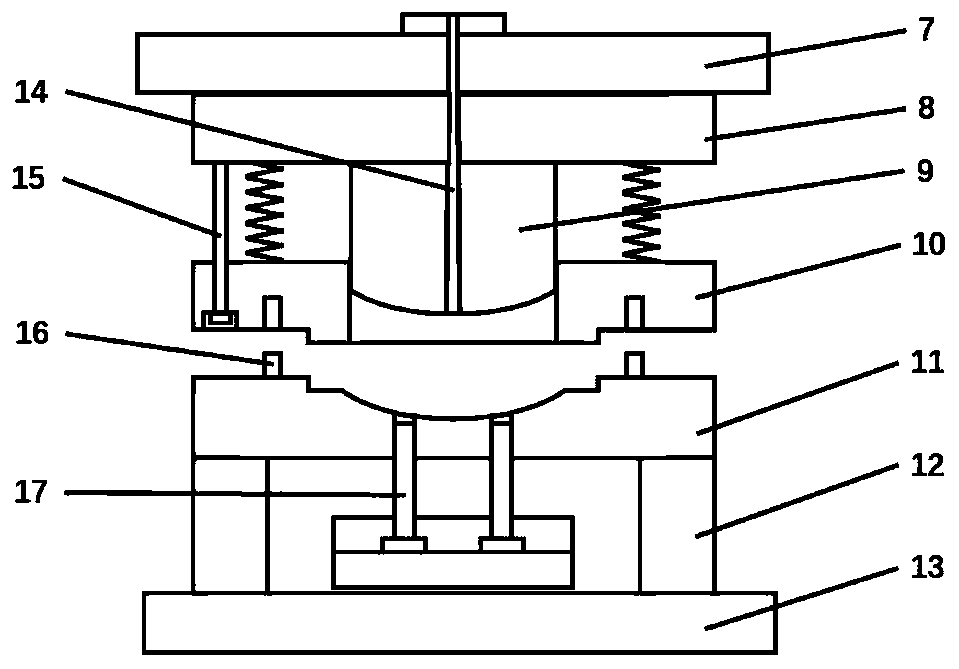

Embodiment 1

[0037] The woven carbon fiber reinforced polypropylene composite material insert (dimensions: length 140mm*width 140mm*height 2mm) that has been cut, cleaned, and dried is placed in the infrared heating furnace 1 by rotating the manipulator, and the insert is heated to heat up to within 10 minutes. 135°C and heat preservation at this temperature for 8 minutes; after the heat preservation is completed, put the composite material insert into the slot of the forming mold by rotating the manipulator 2. The leading part of the injection molding machine pushes the mold partly closed, and the spring blank holder 10 is in contact with the insert and exerts pressure on it. At this time, the polypropylene melt is injected into the cavity; then the mold is pushed to be completely closed and the resin pressure (holding pressure) is maintained. : 3Mpa, holding time: 25s), after the product is cooled, the product is ejected by the ejection mechanism of the injection molding machine, and take...

Embodiment 2

[0039] Place the cut, cleaned and dried braided carbon fiber reinforced polyetheretherketone composite material insert (dimensions: length 140mm*width 140mm*height 3mm) in the infrared heating furnace 1 by rotating the manipulator, and heat the insert to make it within 25min The temperature was raised to 300°C and kept at this temperature for 8 minutes; after the heat preservation was completed, the composite material insert was put into the slot of the forming mold by rotating the manipulator 2 and fixed. The leading part of the injection molding machine pushes the mold partly closed, and the spring blank holder 10 is in contact with the insert and exerts pressure on it. At this time, the short carbon fiber filled polyether ether ketone mixed melt is injected into the cavity; then the mold is pushed to be completely closed and held Resin pressure (holding pressure: 60Mpa, holding time: 25s), after the product is cooled, the product is ejected by the demoulding mechanism of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com