A kind of multi-doped carbon material and its preparation method and application

A carbon material and multi-doping technology, applied in the field of multi-doped carbon material and its preparation, can solve the problems of difficult catalyst structure and performance, and achieve the effects of excellent catalytic activity and stability, and flexible regulation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A preparation of multi-doped carbon material, comprising the steps of:

[0062] 0.35g graphene nanosheets, 0.05g thiourea, 0.25g iron phthalocyanine polymer and 3.5g melamine are put into a stainless steel reaction kettle containing 200 stainless steel grinding balls, wherein the diameter of the stainless steel grinding balls is 5mm, the The volume of the reaction kettle is 60mL, the reaction kettle is sealed, and then the reaction kettle is fixed in a ball mill, and ball milled at 600rpm for 36 hours. After the reaction, the obtained product was repeatedly washed with hot water and ethanol, and then the washed sample was placed in an oven at 60°C for vacuum drying to obtain Fe-N-S doped graphene.

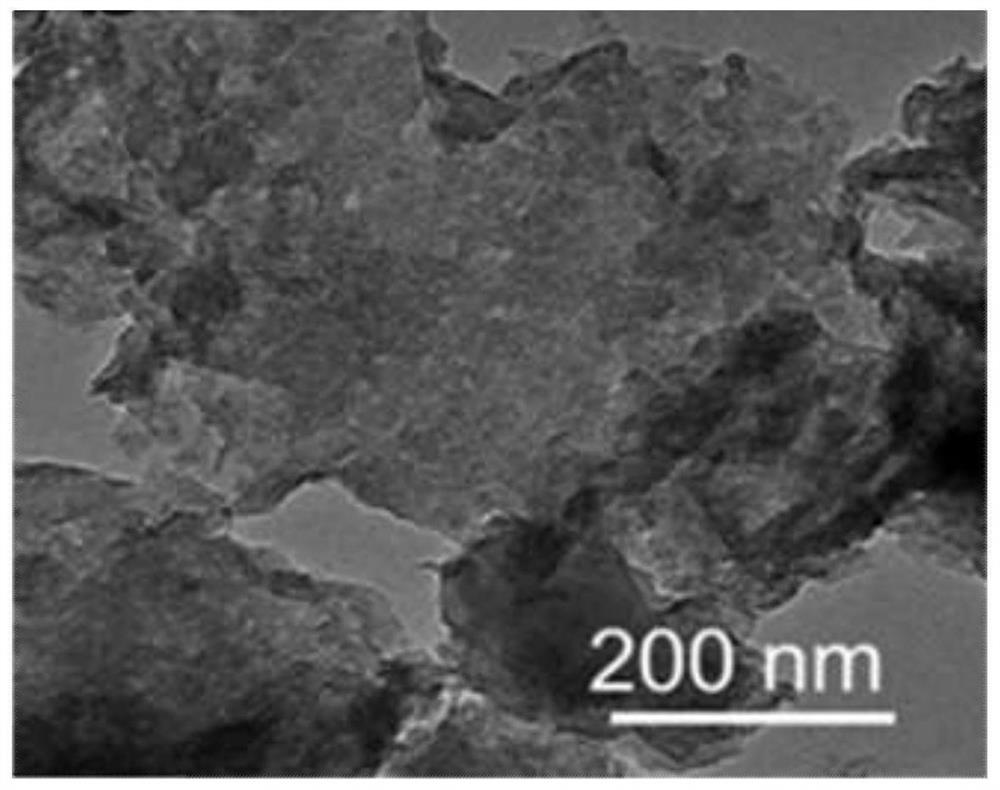

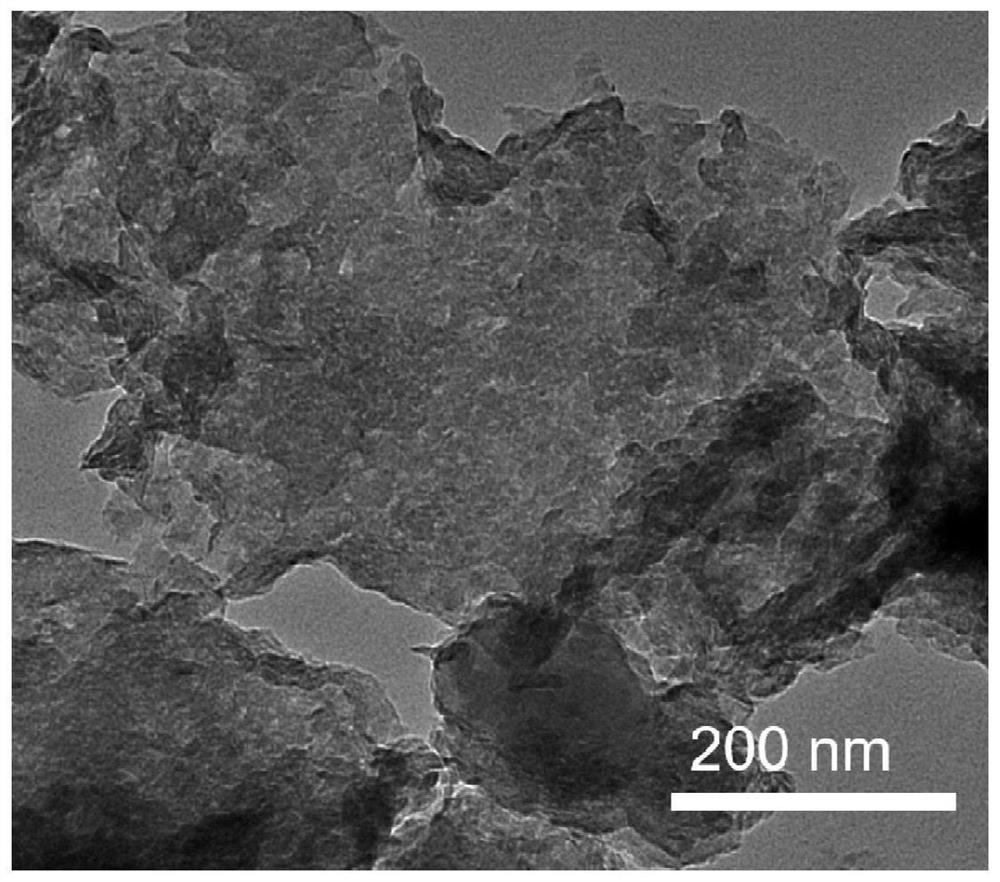

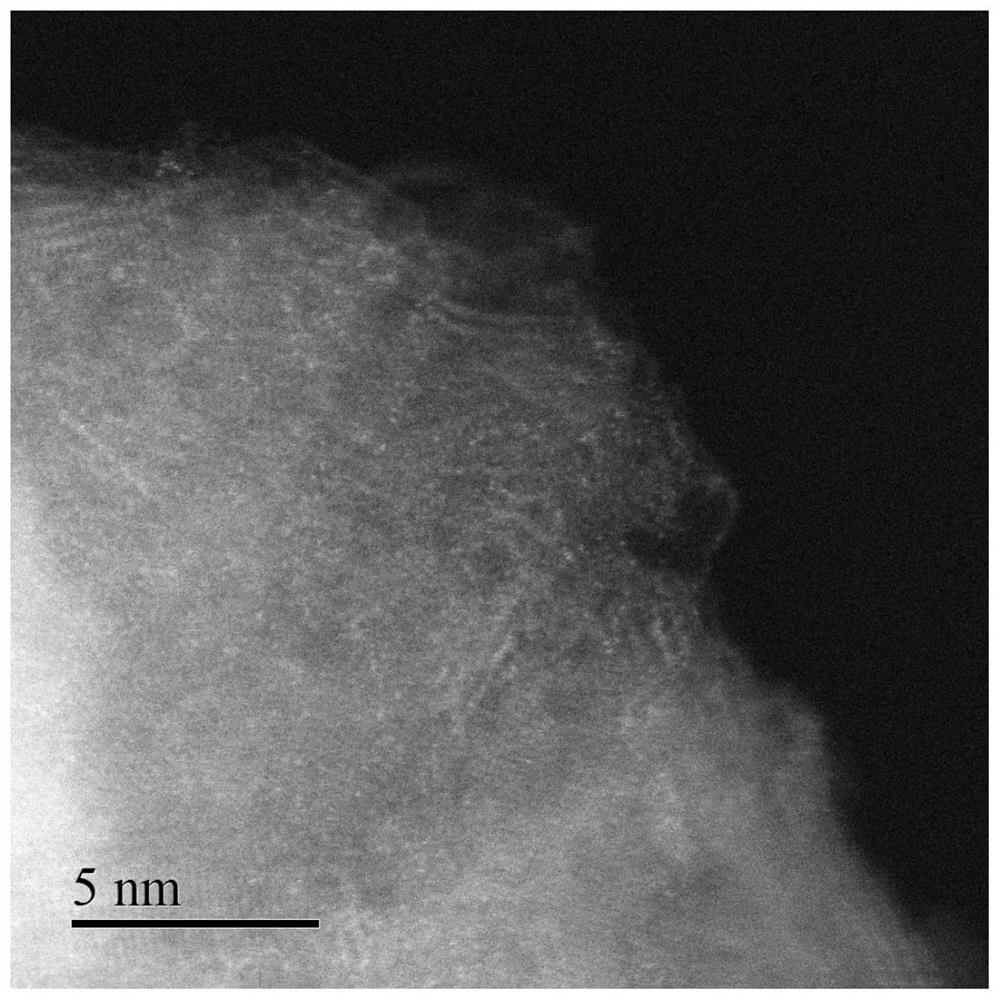

[0063] The prepared Fe-N-S doped graphene was characterized by spherical aberration electron microscope and synchrotron radiation technique, and the results proved that metal Fe was dispersed in nitrogen and sulfur co-doped graphene in the form of single atoms. Such as fig...

Embodiment 2-5

[0076] A kind of preparation of multi-doped carbon material, preparation method is the same as embodiment 1, and difference is only in:

[0077] The dosage of iron phthalocyanine polymer is different, respectively 0.23g, 0.20g, 0.15g, 0.10g, the results are shown in Table 1:

[0078] Table 1 Properties of multi-doped carbon materials prepared with different iron phthalocyanine polymer dosages

[0079]

[0080] The results show that: within the range of the amount of raw materials given in the present invention (that is, the mass ratio of the transition metal compound, the heteroatom-containing compound and the carbon material is 1:8~25:1~3), the obtained Fe-N-S doped Heterographene exhibits excellent catalytic performance, beyond this range, the performance will be reduced.

Embodiment 6-9

[0082] A kind of preparation of multi-doped carbon material, preparation method is the same as embodiment 1, and difference is only in:

[0083] The consumption of melamine is different, respectively 3.2g, 3.0g, 2.5g, 2.0g, the results are shown in Table 2:

[0084] Table 2 Properties of multi-doped carbon materials prepared with different amounts of melamine

[0085]

[0086] The results show that: within the given range of raw material consumption in the present invention (i.e. the mass ratio of the sulfur-containing compound to the nitrogen-containing compound is 1:50 to 120), the obtained Fe-N-S doped graphene exhibits excellent catalytic performance , outside this range, the performance will be degraded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com