Preparation method for high-viscoelasticity and water-retaining edible plasticine

A technology of plasticine and elasticity, which is applied in the field of preparation of edible plasticine with high viscoelasticity and water retention, can solve the problems of drying, cracking, hardening, etc., achieves improved water retention and water absorption performance, improved thermal stability, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

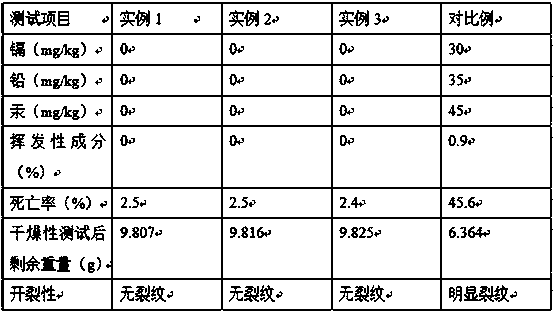

Examples

example 1

[0027] Put 100g of bamboo fiber in a beaker, continue to add 600mL of sodium hydroxide solution with a mass fraction of 40% to the beaker, stir to obtain a cellulose suspension, filter the cellulose suspension, remove the filtrate to obtain alkalized cellulose, and prepare Put the alkalized cellulose into a four-necked flask with a stirrer and a dropping funnel, add 400mL of sodium hydroxide solution with a mass fraction of 25% into the four-necked flask, heat up to 60°C, and use the dropping funnel to Add 15 mL of carbon disulfide dropwise to a four-neck flask at a rate of 3 mL / min, stir and react for 2 hours to obtain a reaction product; mix the above reaction product with 400 mL of magnesium sulfate solution with a mass fraction of 25% and stir for 30 min, filter, remove the filtrate to obtain a filter residue , wash the filter residue with absolute ethanol, place it in an oven, heat up to 50°C, and dry for 2 hours to obtain solid cellulose xanthate. Add 100 mL of sodium hyd...

example 2

[0029] Put 110g of bamboo fiber in a beaker, continue to add 650mL of sodium hydroxide solution with a mass fraction of 40% to the beaker, stir to obtain a cellulose suspension, suction filter the cellulose suspension, remove the filtrate to obtain alkalized cellulose, and prepare Put the alkalized cellulose into a four-necked flask with a stirrer and a dropping funnel, add 420mL of sodium hydroxide solution with a mass fraction of 25% into the four-necked flask, heat up to 62°C, and use the dropping funnel to Add 17 mL of carbon disulfide dropwise to a four-necked flask at a rate of 4 mL / min, stir and react for 2.5 h to obtain a reaction product; mix and stir the above reaction product with 450 mL of 25% magnesium sulfate solution for 32 min, filter, and remove the filtrate to obtain Filter the residue, wash the filter residue with absolute ethanol, place it in an oven, heat up to 52°C, and dry for 2.5 hours to obtain solid cellulose xanthate. Add 110 mL of hydrogen with a mas...

example 3

[0031] Put 120g of bamboo fibers in a beaker, continue to add 700mL of sodium hydroxide solution with a mass fraction of 40% to the beaker, stir to obtain a cellulose suspension, suction filter the cellulose suspension, remove the filtrate to obtain alkalized cellulose, and prepare Put the alkalized cellulose into a four-necked flask with a stirrer and a dropping funnel, add 450mL of sodium hydroxide solution with a mass fraction of 25% into the four-necked flask, heat up to 65°C, and use the dropping funnel to Add 18 mL of carbon disulfide dropwise to a four-neck flask at a dropping rate of 5 mL / min, stir and react for 3 h to obtain a reaction product; mix and stir the above reaction product with 500 mL of 25% magnesium sulfate solution for 35 min, filter, remove the filtrate to obtain a filter residue , wash the filter residue with absolute ethanol, place it in an oven, heat up to 55°C, and dry for 3 hours to obtain solid cellulose xanthate. Add 120 mL of sodium hydroxide wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com