Method for producing black aluminum profile by using anodized single nickel salt for coloring and aluminum profile

A technology of anodizing and aluminum profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A method for producing black aluminum profiles using anodized single nickel salt coloring.

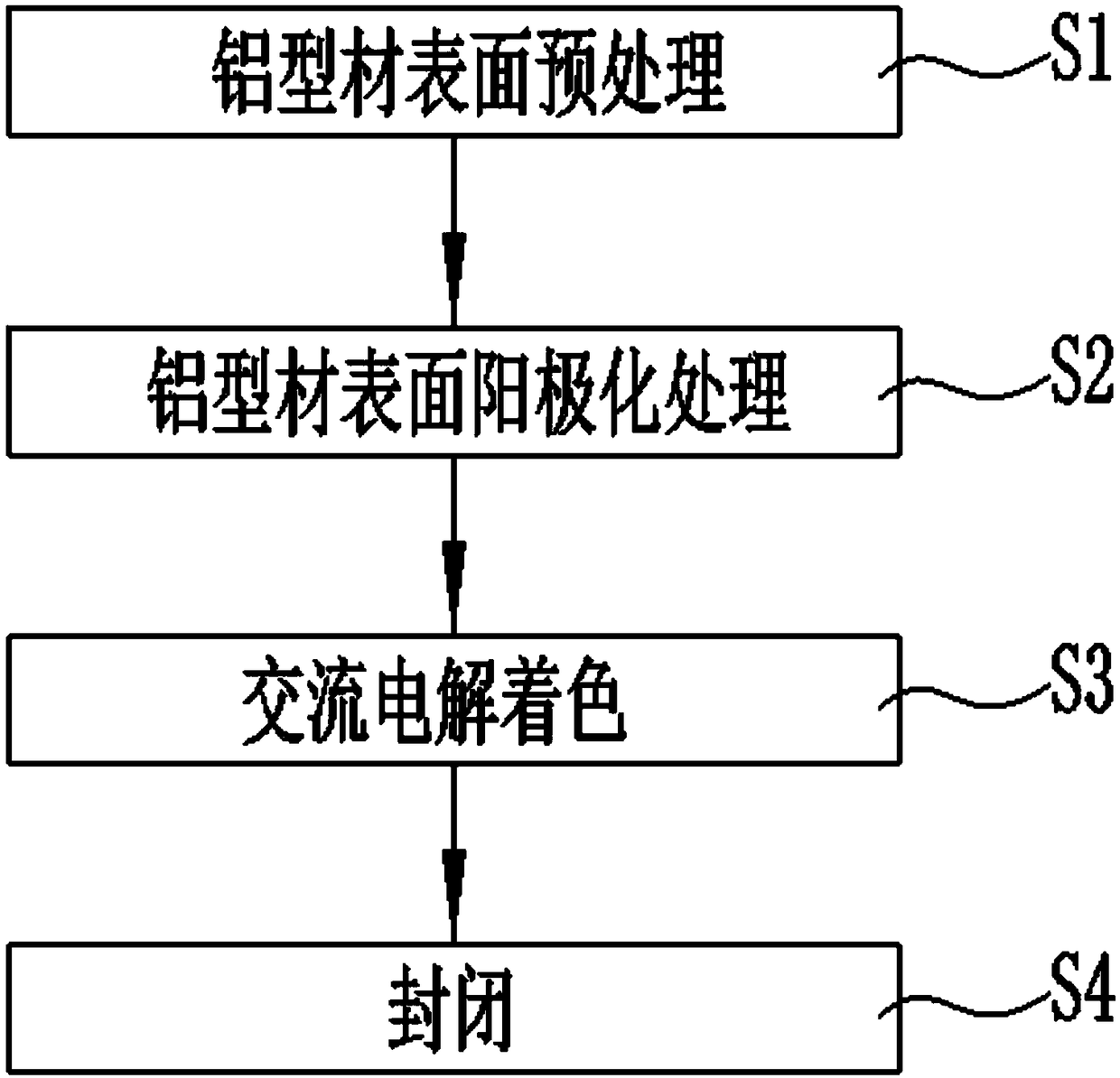

[0029] refer to figure 1 As shown, a method for producing black aluminum profiles using anodized single nickel salt coloring specifically includes the following steps:

[0030] S1. Surface pretreatment of aluminum profiles: use daily detergent to clean the grease and dirt on the surface of aluminum profiles, rinse them with deionized water; Perform electrochemical polishing in a 1:6 mixed solution of perchloric acid and absolute ethanol for 3 minutes at a reaction temperature of 25°C to remove scratches on the surface of the aluminum profile and improve the smoothness of the surface of the aluminum profile. Pretreatment of the surface of the aluminum profile can effectively Improve the anodizing treatment and coloring effect of subsequent aluminum profiles;

[0031] S2. Surface anodization treatment of aluminum profile: use the aluminum profile after surface pret...

Embodiment 2

[0039] Embodiment 2: A method for producing black aluminum profiles using anodized single nickel salt coloring.

[0040] refer to figure 1 As shown, a method for producing black aluminum profiles using anodized single nickel salt coloring specifically includes the following steps:

[0041] S1. Surface pretreatment of aluminum profiles: use daily detergent to clean the grease and dirt on the surface of aluminum profiles, rinse them with deionized water; Perform electrochemical polishing in a 1:5 mixed solution of perchloric acid and absolute ethanol for 2 minutes at a reaction temperature of 25°C to remove scratches on the surface of the aluminum profile and improve the smoothness of the surface of the aluminum profile. Pretreatment of the surface of the aluminum profile can effectively Improve the anodizing treatment and coloring effect of subsequent aluminum profiles;

[0042] S2. Surface anodization treatment of aluminum profile: use the aluminum profile after surface pret...

Embodiment 3

[0048] Embodiment 3: A method for producing black aluminum profiles by using anodized single nickel salt coloring.

[0049] refer to figure 1 As shown, a method for producing black aluminum profiles using anodized single nickel salt coloring specifically includes the following steps:

[0050] S1. Surface pretreatment of aluminum profiles: use daily detergent to clean the grease and dirt on the surface of aluminum profiles, rinse them with deionized water; Perform electrochemical polishing in a 1:8 mixed solution of perchloric acid and absolute ethanol for 5 minutes at a reaction temperature of 25°C to remove scratches on the surface of the aluminum profile and improve the smoothness of the surface of the aluminum profile. Pretreatment of the surface of the aluminum profile can effectively Improve the anodizing treatment and coloring effect of subsequent aluminum profiles;

[0051] S2. Surface anodization treatment of aluminum profile: use the aluminum profile after surface p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com