Perovskite solar cell based on copper-indium-sulfur nanocrystals and preparation method thereof

A technology of solar cells and nanocrystals, applied in the field of solar cells, can solve the problems of high price, high cost of solar cells, and complicated synthesis process, and achieve the effects of short reaction time, high photoelectric conversion efficiency, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

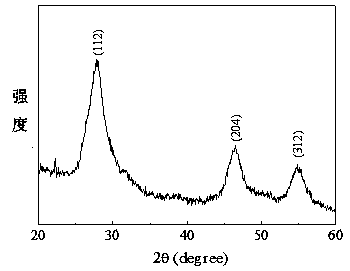

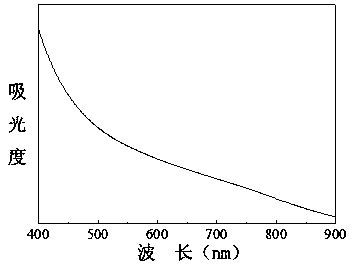

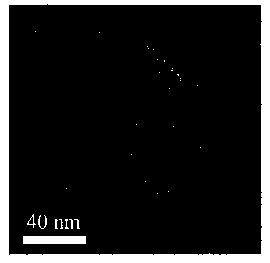

[0038] a CuInS 2 A method for preparing nanocrystals, comprising the steps of:

[0039] 1) Add 1 mmol of sublimed sulfur powder into 1 ml of diphenylphosphine (DPP) solution and dissolve it by ultrasonic to form a transparent light yellow DPP-S precursor solution.

[0040] 2) Mix 0.3 mmol cuprous iodide (CuI), 0.3 mmol indium acetate (In(OAC) 3 ), 6.0 ml oleylamine and 6.0 ml octadecene (ODE) were mixed to obtain A solution, which was filled into a three-necked flask with nitrogen gas, stirred and dissolved, and the solution was slowly heated to 90 ° C, and kept at this temperature for 10 min. Then, it was heated to 180°C.

[0041] 3) At 180°C, inject the DDP-S precursor solution obtained in step 1) into the solution A in the three-necked flask. min. Then start to lower the temperature (natural cooling is enough here, no speed requirement), when the temperature of the solution drops to 90°C, inject 10 ml of n-hexane into the mixed solution, and lower the mixed solution to r...

Embodiment 2

[0048] The difference from Example 1 is:

[0049] 1) In step 1), 0.5 mmol of sublimated sulfur powder and 0.5 ml of diphenylphosphine (DPP) are used.

[0050] 2) In step 2), copper iodide (CuI) is 0.1 mmol, indium acetate (In(OAC) 3 ) is 0.1 mmol, oleylamine is 4.0 ml, and octadecene (ODE) is 4.0 ml.

Embodiment 3

[0052] The difference from Example 1 is:

[0053] 1) In step 1), 1.5 mmol of sublimated sulfur powder and 1.5 ml of diphenylphosphine (DPP) were used.

[0054] 2) In step 2), copper iodide (CuI) is 0.5 mmol, indium acetate (In(OAC) 3 ) is 0.5mmol, oleylamine is 8.0ml, and octadecene (ODE) is 8.0ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com