Strawberry fruit paste and preparation method thereof

A technology of strawberry fruit and fruit puree, which is applied in the directions of food preservation, food ingredients as taste improvers, food ingredients as taste improvers, etc. It can solve the problems of lack of market, single product form, and few varieties of fruit puree products, etc., and achieve high Viscous, high anti-browning performance, food safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of strawberry fruit puree, is made up of fruit puree base and the sesame filling that is coated in the fruit puree base, the weight ratio of described fruit puree base and sesame filling is 13:1.5;

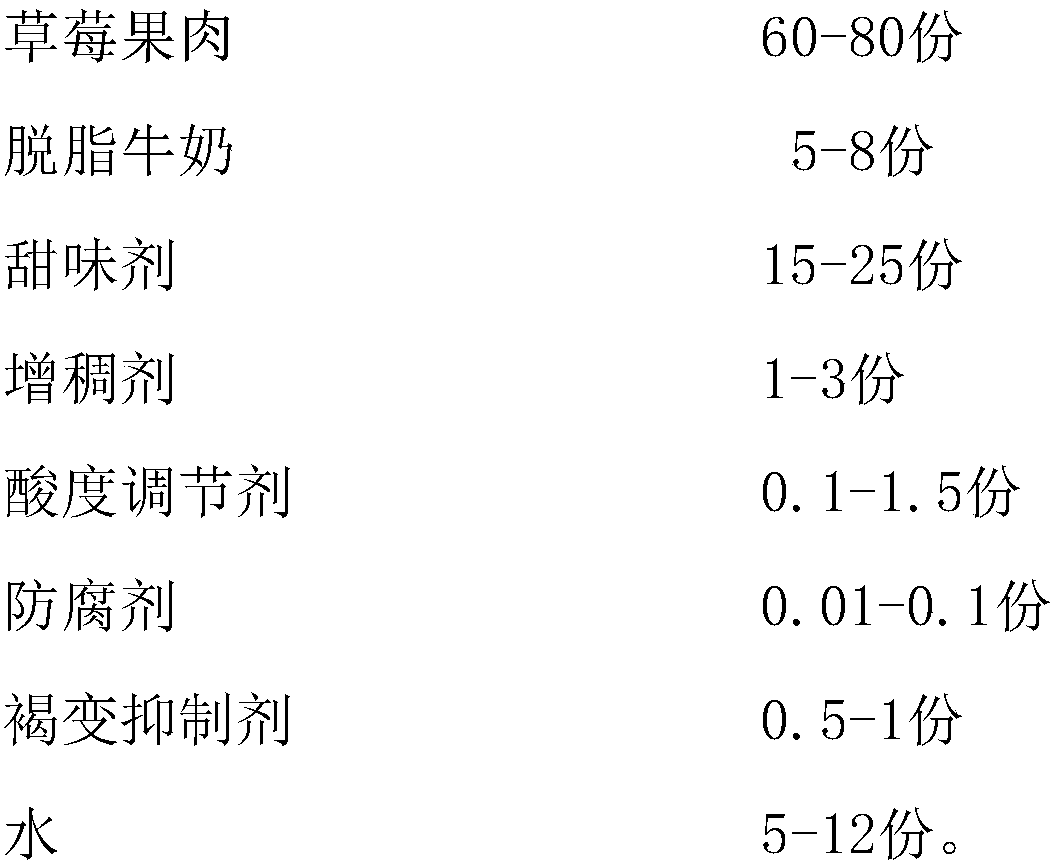

[0047] Wherein, each part of the fruit puree matrix includes the raw materials of the following parts by weight:

[0048]

[0049] The sesame stuffing and skimmed milk in this example are commonly used sesame stuffing and skimmed milk on the market.

[0050] The sweetener is a mixture of white sugar, fructose syrup and xylitol in a weight ratio of 3:2.5:1; the thickener is a mixture of pectin and xanthan gum in a weight ratio of 4:1.

[0051] The acidity regulator is citric acid; the preservative is a mixture of sorbic acid and potassium sorbate at a weight ratio of 1:1.5.

[0052] The browning inhibitor is a mixture composed of sodium D-isoascorbate, L-cysteine and phytic acid in a weight ratio of 4.5:6:1.5.

[0053] A preparation method of strawberry puree a...

Embodiment 2

[0062] A kind of strawberry fruit puree, is made up of fruit puree base and the sesame filling that is coated in the fruit puree base, the weight ratio of described fruit puree base and sesame filling is 10:1;

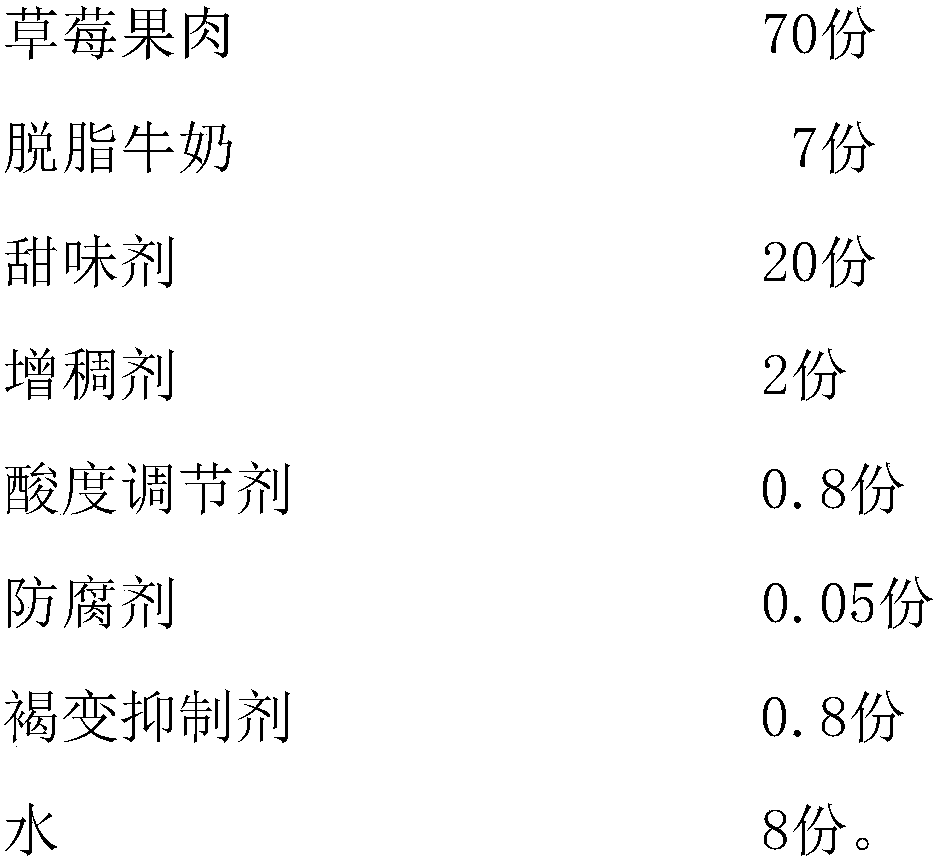

[0063] Wherein, each part of the fruit puree matrix includes the raw materials of the following parts by weight:

[0064]

[0065] The sesame stuffing and skimmed milk in this example are commonly used sesame stuffing and skimmed milk on the market.

[0066] The sweetener is a mixture of white sugar, fructose syrup and xylitol in a weight ratio of 2.5:2:1; the thickener is a mixture of pectin and xanthan gum in a weight ratio of 3:1.

[0067] The acidity regulator is citric acid; the preservative is a mixture of sorbic acid and potassium sorbate in a weight ratio of 1:1.

[0068] The browning inhibitor is a mixture composed of sodium D-isoascorbate, L-cysteine and phytic acid in a weight ratio of 4:5:1.

[0069] A preparation method of strawberry puree as descri...

Embodiment 3

[0078] A kind of strawberry fruit puree, is made up of fruit puree matrix and the sesame filling that is coated in the fruit puree matrix, the weight ratio of described fruit puree matrix and sesame filling is 16:2;

[0079] Wherein, each part of the fruit puree matrix includes the raw materials of the following parts by weight:

[0080]

[0081]

[0082] The sesame stuffing and skimmed milk in this example are commonly used sesame stuffing and skimmed milk on the market.

[0083] The sweetener is a mixture of white sugar, fructose syrup and xylitol in a weight ratio of 3.5:3:1; the thickener is a mixture of pectin and xanthan gum in a weight ratio of 5:1.

[0084] The acidity regulator is citric acid; the preservative is a mixture of sorbic acid and potassium sorbate at a weight ratio of 1:2.

[0085] The browning inhibitor is a mixture composed of sodium D-isoascorbate, L-cysteine and phytic acid in a weight ratio of 5:7:2.

[0086] A preparation method of strawber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com