A continuous flow polymerization-polymerization coupling method for preparing functionalized polyolefins

A polyolefin and functionalization technology, which is applied in the field of continuous flow polymerization-polymerization coupling to prepare functionalized polyolefins, can solve the problems of low conversion efficiency of active centers, harsh reaction conditions, cumbersome process routes, etc., avoiding operation steps and improving transmission efficiency. quality, avoid the effect of oxidative inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

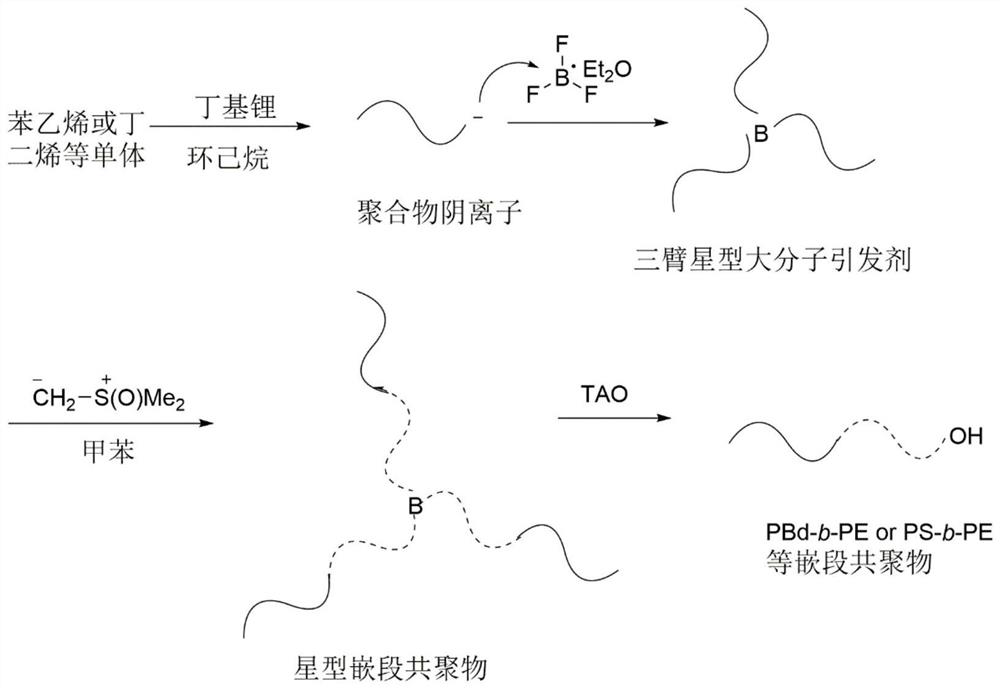

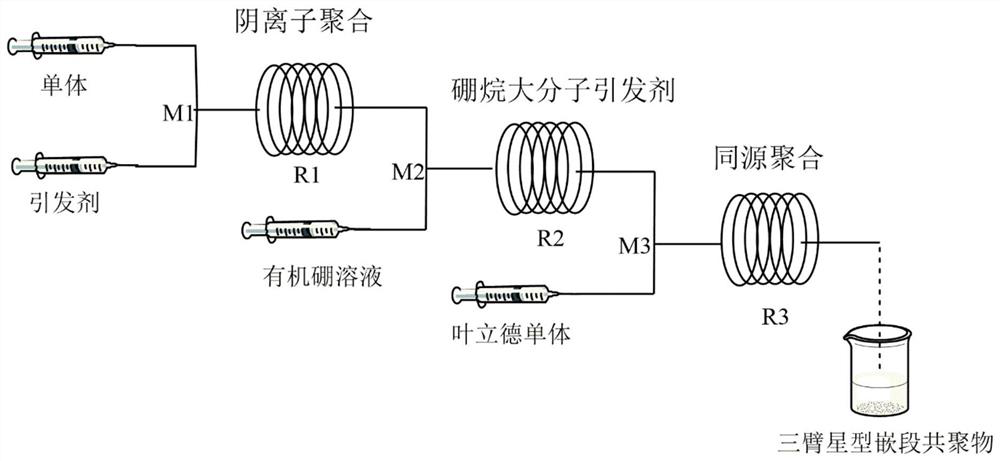

Method used

Image

Examples

Embodiment 1

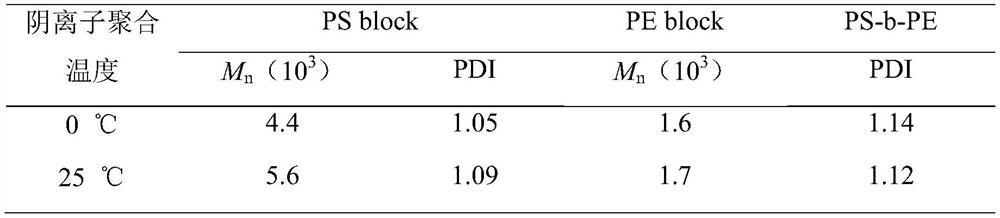

[0035](1) Anionic polymerization: Take purified styrene (7.2mL, 63mmol) in the glove box and dissolve it in 22.8mL cyclohexane, and the 1-1 solution (2.1mol / L, 135eq) is prepared; take sec-butyllithium (1mL, 1.3mmol) was dissolved in 29mL cyclohexane, and the 1-2 solution (0.047mol / L, 3eq) was configured; the 1-1 solution and 1-2 solution were used at the same flow rate (0.04 mL / min) into T-type mixer M1 and tubular reactor R1. The tubular reactor was placed in a magnetic stirrer to control the temperature, the reaction temperature was controlled at 0°C and 25°C respectively, the residence time of the reaction was 25min, and the A solution was obtained from the reaction.

[0036] (2) Synthesis of macromolecular borane initiator: take BF in the glove box 3 OEt 2 The solution (0.7mL, 0.48mmol) was dissolved in 29.4mL cyclohexane, and the 2-1 solution (0.016mol / L, 1eq) was prepared; the 2-1 solution was reacted with the A solution obtained in step (1) at the same flow rate (16...

Embodiment 2

[0044] (1) Anionic polymerization: prepare respectively cyclohexane solution 1-1 (1.41mol / L, 90eq; 2.10mol / L, 135eq; 2.82mol / L, 180eq) of styrene in the glove box; take sec-butyllithium ( 1mL, 1.3mmol) was dissolved in 29mL cyclohexane, and the 1-2 solution (0.047mol / L, 3eq) was prepared; the 1-1 solution and 1-2 solution were used at the same flow rate (0.04mL / min) into the T-type mixer M1 and the tubular reactor R1. The tubular reactor was placed in a magnetic stirrer to control the temperature, the reaction temperature was controlled at 25° C., the residence time of the reaction was 25 min, and A solution was obtained from the reaction.

[0045] (2) Synthesis of macromolecular borane initiator: take BF in the glove box 3 OEt 2 The solution (0.7mL, 0.48mmol) was dissolved in 29.4mL cyclohexane, and the 2-1 solution (0.016mol / L, 1eq) was prepared; the 2-1 solution was reacted with the A solution obtained in step (1) at the same flow rate (16 μL / min) into the T-type mixer ...

Embodiment 3

[0053] (1) Anionic polymerization: prepare cyclohexane solutions 1-1 (2.1mol / L, 135eq) of styrene, butadiene, isobutylene or methyl methacrylate in the glove box; take sec-butyllithium (1mL, 1.3mmol) was dissolved in 29mL cyclohexane, and the 1-2 solution (0.047mol / L, 3eq) was prepared; the 1-1 solution and 1-2 solution were used at the same flow rate (0.04mL / min ) into the T-type mixer M1 and the tubular reactor R1. The tubular reactor was placed in a magnetic stirrer to control the temperature, the reaction temperature was controlled at 25° C., the residence time of the reaction was 25 min, and A solution was obtained from the reaction.

[0054] (2) Synthesis of macromolecular borane initiator: take BF in the glove box 3 OEt 2 The solution (0.7mL, 0.48mmol) was dissolved in 29.4mL cyclohexane, and the 2-1 solution (0.016mol / L, 1eq) was prepared; the 2-1 solution was reacted with the A solution obtained in step (1) at the same flow rate (16 μL / min) into the T-type mixer M2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com