High-performance environmentally friendly chloroprene rubber adhesive by composite grafting

A neoprene and adhesive technology, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the health threats of front-line production workers, poor adhesion of complex materials, unstable quality, etc. problems, to achieve the effect of promoting the atmosphere effect, strong comprehensive performance, and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

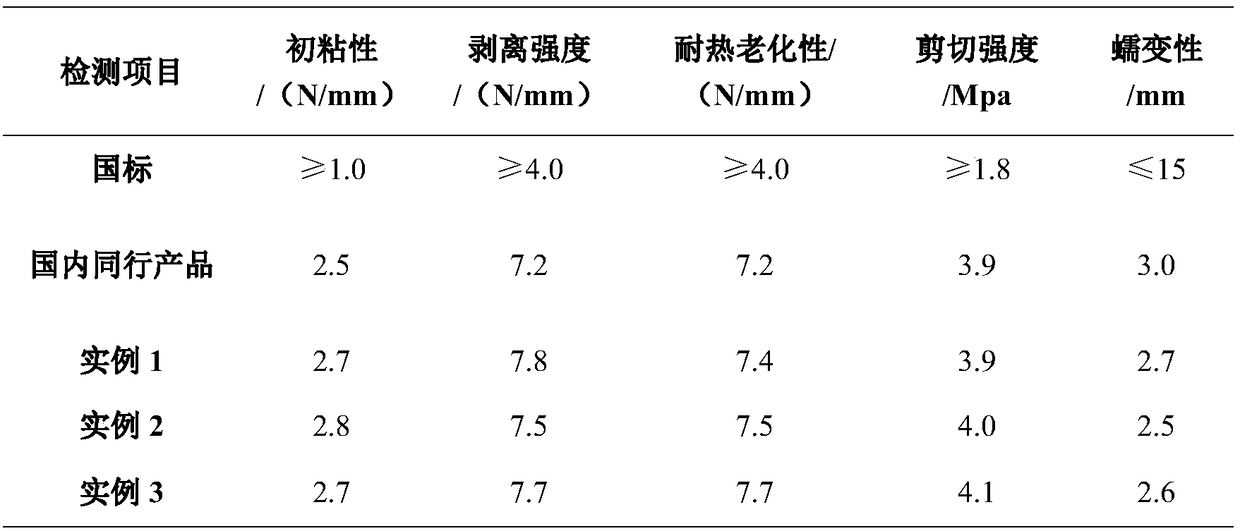

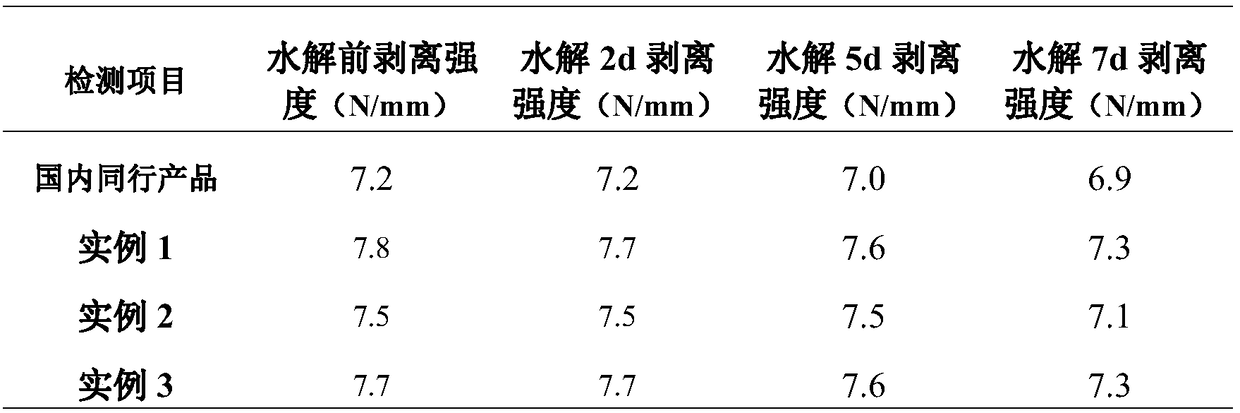

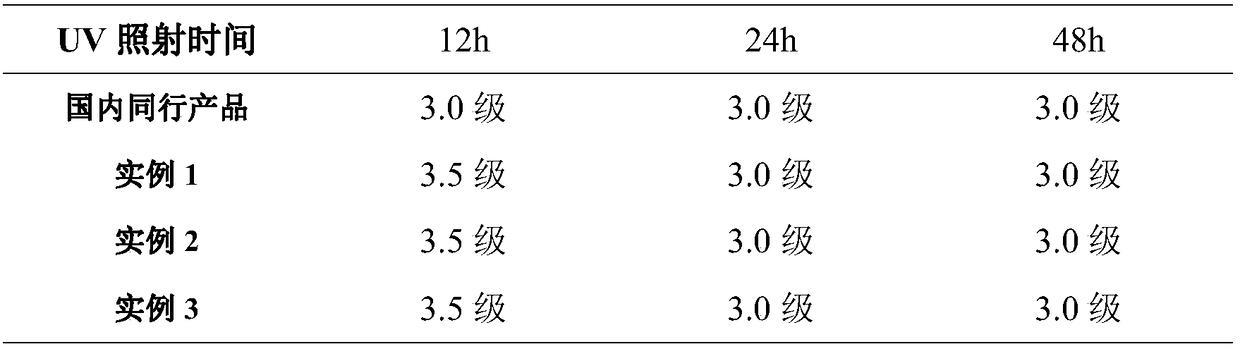

Examples

Embodiment 1

[0024] 1) Add 50 parts of acetone, 150 parts of butanone, 150 parts of ethyl acetate, 120 parts of dimethyl carbonate, and 200 parts of methylcyclohexane in sequence, adjust the speed to 350r / min-450r / min, and stir evenly.

[0025] 2) Raise the temperature to 51-59°C, control the stirring speed at 550r / min-750r / min, add 100 parts of chloroprene rubber and 40 parts of chlorinated polypropylene, and stir for 2.5-3.5 hours.

[0026] 3) Keep the reflux temperature at 72-88°C and the stirring speed at 30-70r / min. Add 3 parts of initiator BPO, continue stirring for 15 minutes, and then add 100 parts of methyl methacrylate dropwise.

[0027] 4) After reacting for 1.5-3 hours, add 10 parts of maleic anhydride, when the viscosity reaches 3000-4000cps, the reaction is considered to be over.

[0028] 5) Lower the temperature to below 50°C, stir at a speed of 90r / min-150r / min, and add 8 parts of terminator BHT.

[0029] 6) Finally, add 15 parts of terpene phenolic resin T-803L and 15 pa...

Embodiment 2

[0031] 1) After sequentially adding 40 parts of acetone, 160 parts of butanone, 150 parts of ethyl acetate, 110 parts of dimethyl carbonate, and 210 parts of methylcyclohexane, adjust the speed to 350r / min-450r / min and stir evenly.

[0032] 2) Raise the temperature to 51-59°C, control the stirring speed at 550r / min-750r / min, add 100 parts of chloroprene rubber and 50 parts of chlorinated polypropylene, and stir for 2.5-3.5 hours.

[0033] 3) Keep the reflux temperature at 72-88°C and the stirring speed at 30-70r / min. Add 3 parts of initiator BPO, continue to stir for 15 minutes, and then add 80 parts of methyl methacrylate dropwise.

[0034] 4) After reacting for 1.5-3 hours, add 12 parts of maleic anhydride, when the viscosity reaches 3000-4000cps, the reaction is considered to be over.

[0035] 5) Lower the temperature to below 50°C, stir at a speed of 90r / min-150r / min, and add 8 parts of terminator BHT.

[0036] 6) Finally, add 14 parts of terpene phenolic resin T-803L an...

Embodiment 3

[0038] 1) Add 60 parts of acetone, 140 parts of butanone, 150 parts of ethyl acetate, 130 parts of dimethyl carbonate, and 190 parts of methylcyclohexane in sequence, adjust the speed to 350r / min-450r / min, and stir evenly.

[0039] 2) Raise the temperature to 51-59°C, control the stirring speed at 550r / min-750r / min, add 100 parts of chloroprene rubber and 30 parts of chlorinated polypropylene, and stir for 2.5-3.5 hours.

[0040] 3) Keep the reflux temperature at 72-88°C and the stirring speed at 30-70r / min. Add 3 parts of initiator BPO, continue to stir for 15 minutes, and then add 120 parts of methyl methacrylate dropwise.

[0041] 4) After reacting for 1.5-3 hours, add 8 parts of maleic anhydride, when the viscosity reaches 3000-4000cps, the reaction is considered to be over.

[0042] 5) Lower the temperature to below 50°C, stir at a speed of 90r / min-150r / min, and add 8 parts of terminator BHT.

[0043] 6) Finally, add 15 parts of terpene phenolic resin T-803L and 15 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com