Method for detecting content of impurity elements in aluminum alloy powder

A detection method and impurity element technology, which is applied in the detection field of impurity element content in aluminum alloy powder, can solve the problems of being unable to compress dense bulk samples and fail to meet the requirements of GD-MS analysis, and achieve low detection limit, dynamic The effect of wide linear range and less matrix interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Put the aluminum alloy powder 1# sample to be tested into a high-purity graphite crucible, heat it to 1200°C in a high-purity helium-protected atmosphere furnace, and keep it warm for 4 hours to heat the aluminum alloy powder to a molten state.

[0050] (2) After a period of cooling at room temperature, the aluminum alloy powder sample condenses into an irregular block aluminum alloy sample.

[0051] (3) Under the pressure of 5KN, the SYP-30TS manual tablet press (Shanghai Xinnuo Instrument) was used to press repeatedly, and the sample was pressed into a sheet sample with a diameter of 20mm and a thickness of 4mm to obtain an aluminum alloy sample.

[0052] (4) The aluminum alloy sample is ultrasonically cleaned twice in pure water, finally ultrasonically cleaned with ethanol, and dried.

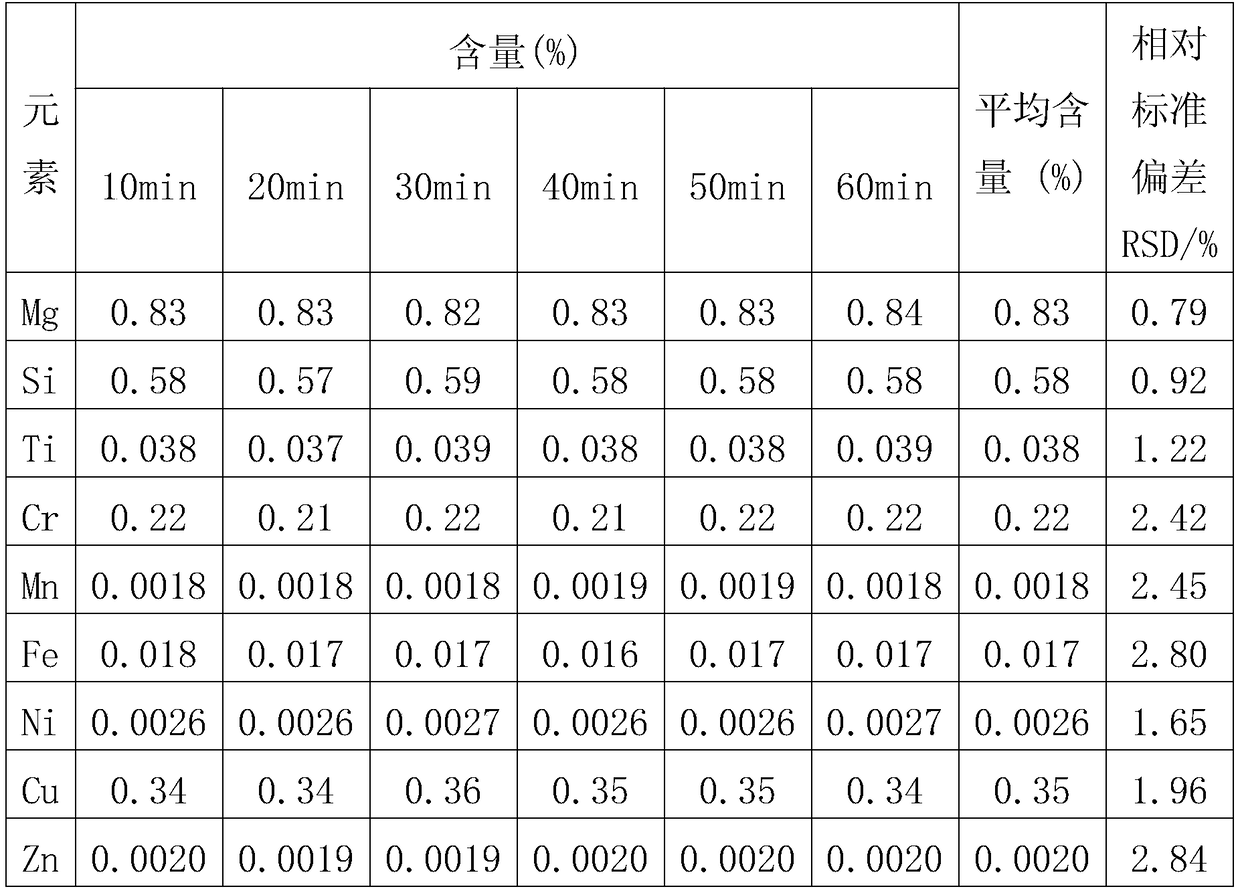

[0053] (5) Put the cleaned aluminum alloy sample into the GD-MS sample holder, use Element GD glow discharge mass spectrometer, the best working conditions in DC mode are: dischar...

Embodiment 2

[0061] (1) Put aluminum alloy standard sample 6063-1 (Standard Sample Research Institute of Shandong Academy of Metallurgical Sciences, chips) into a high-purity graphite crucible, heat it to 1200°C for 4 hours in a high-purity helium-protected atmosphere furnace , the aluminum alloy powder is heated to a molten state.

[0062] (2) After a period of cooling at room temperature, the aluminum alloy powder sample condenses into an irregular block aluminum alloy sample.

[0063] (3) Under a pressure of about 5KN, use a SYP-30TS manual tablet press (Shanghai Xinnuo Instrument) to press repeatedly to press the sample into a sheet sample with a diameter of 20mm and a thickness of 6mm to obtain an aluminum alloy sample.

[0064] (4) The aluminum alloy sample is ultrasonically cleaned twice in pure water, finally ultrasonically cleaned with ethanol, and dried.

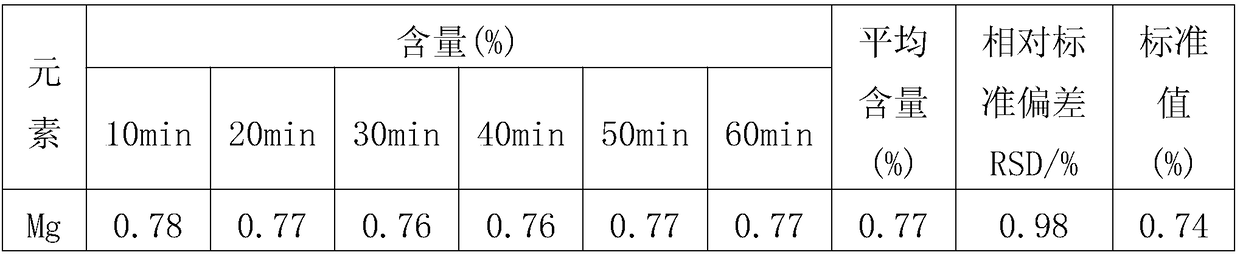

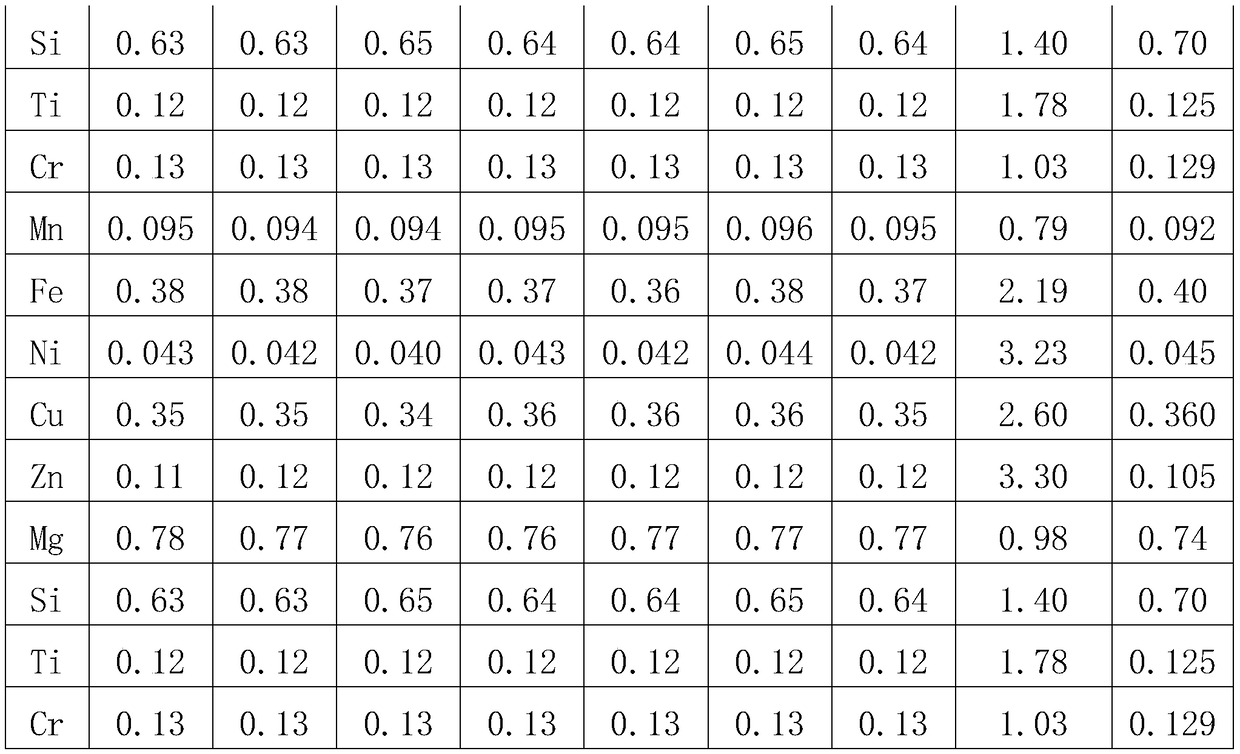

[0065] (5) Put the cleaned aluminum alloy sample into the GD-MS sample holder, use Element GD glow discharge mass spectromet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com