Flexible electronic skin capable of sensing pressure and preparation method thereof

An electronic skin and pressure-sensing technology, which is applied in the field of flexible sensors, can solve the problems of capacitive pressure sensor interference and lower sensitivity, and achieve the effects of avoiding shedding and loosening, simplifying the preparation process, and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

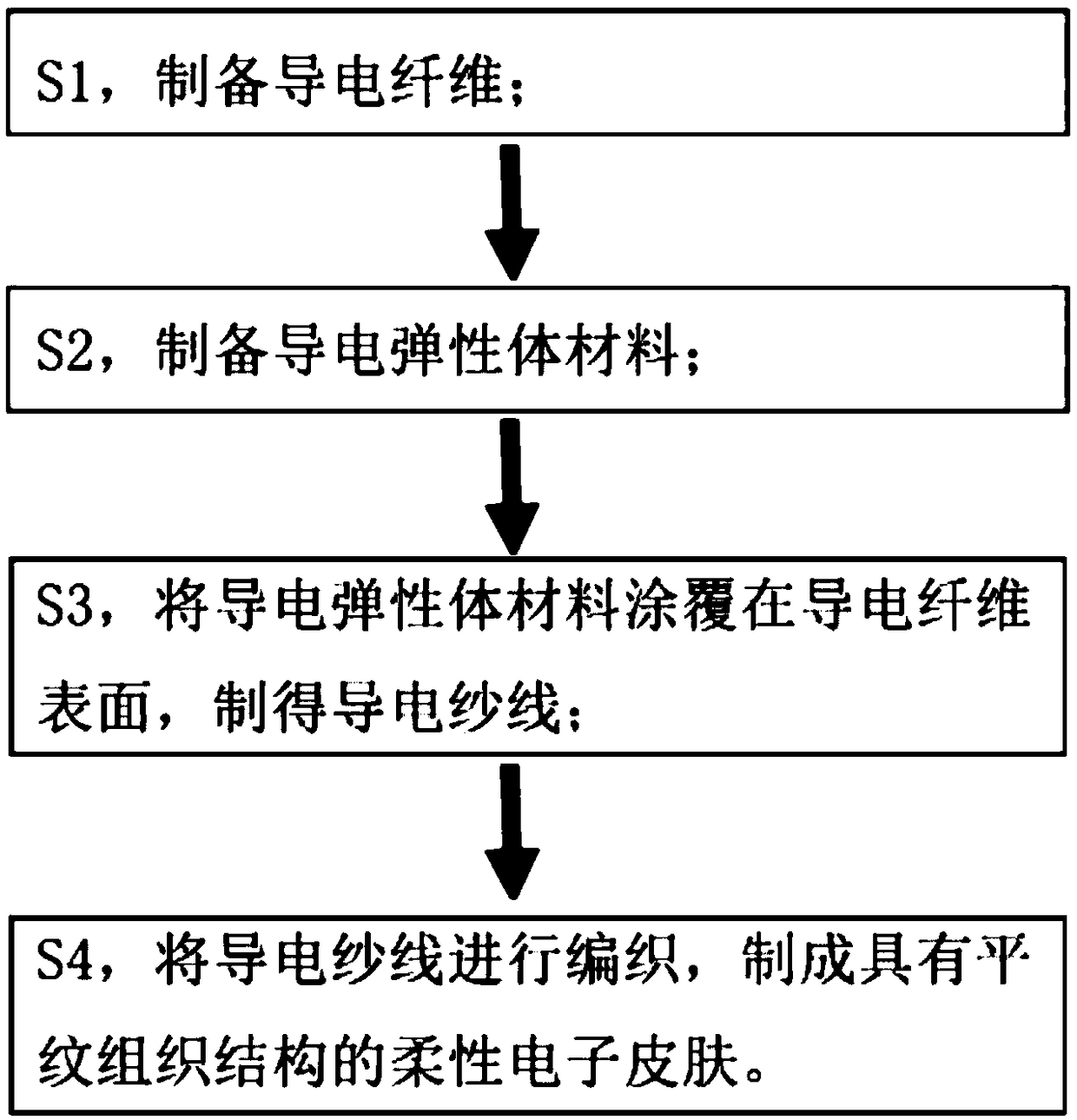

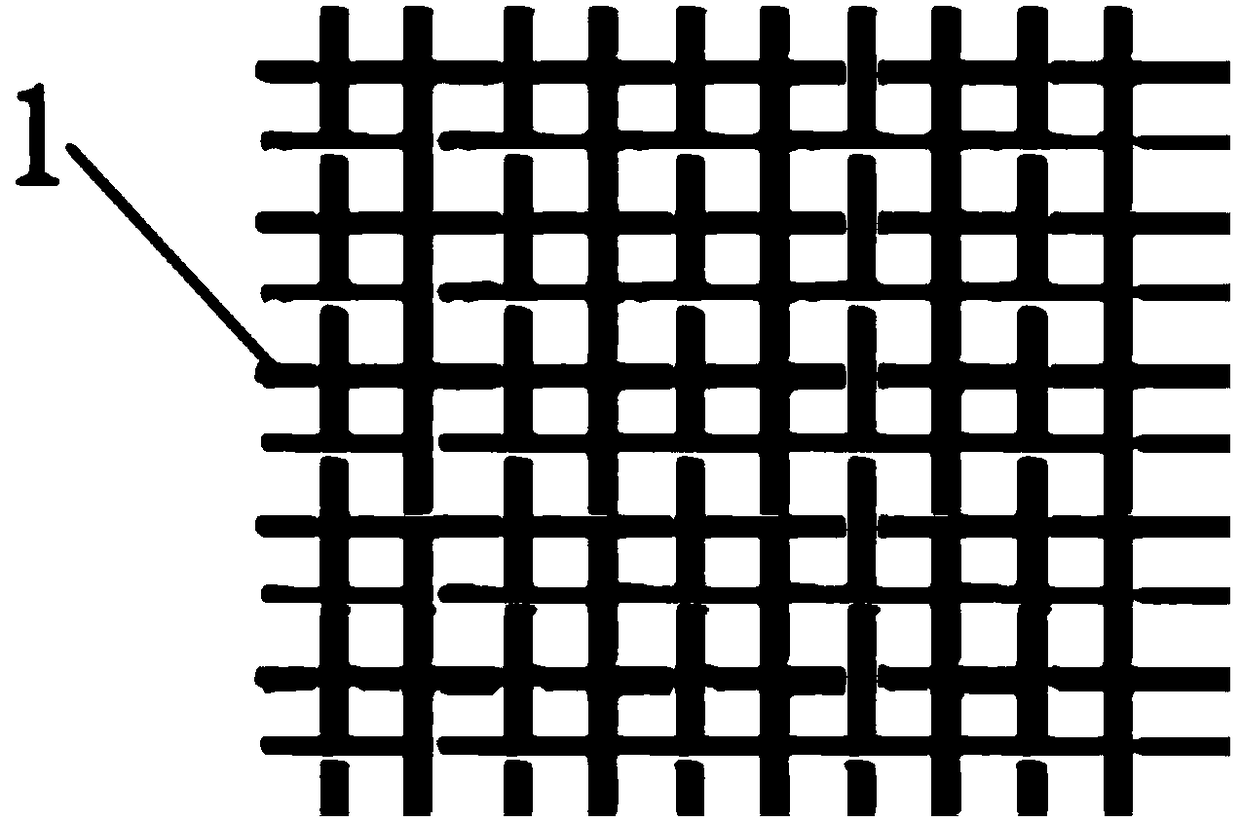

[0025] The embodiment of the present invention also provides a method for preparing a flexible electronic skin capable of sensing pressure, including the following steps:

[0026] S1, preparing the conductive fiber 11.

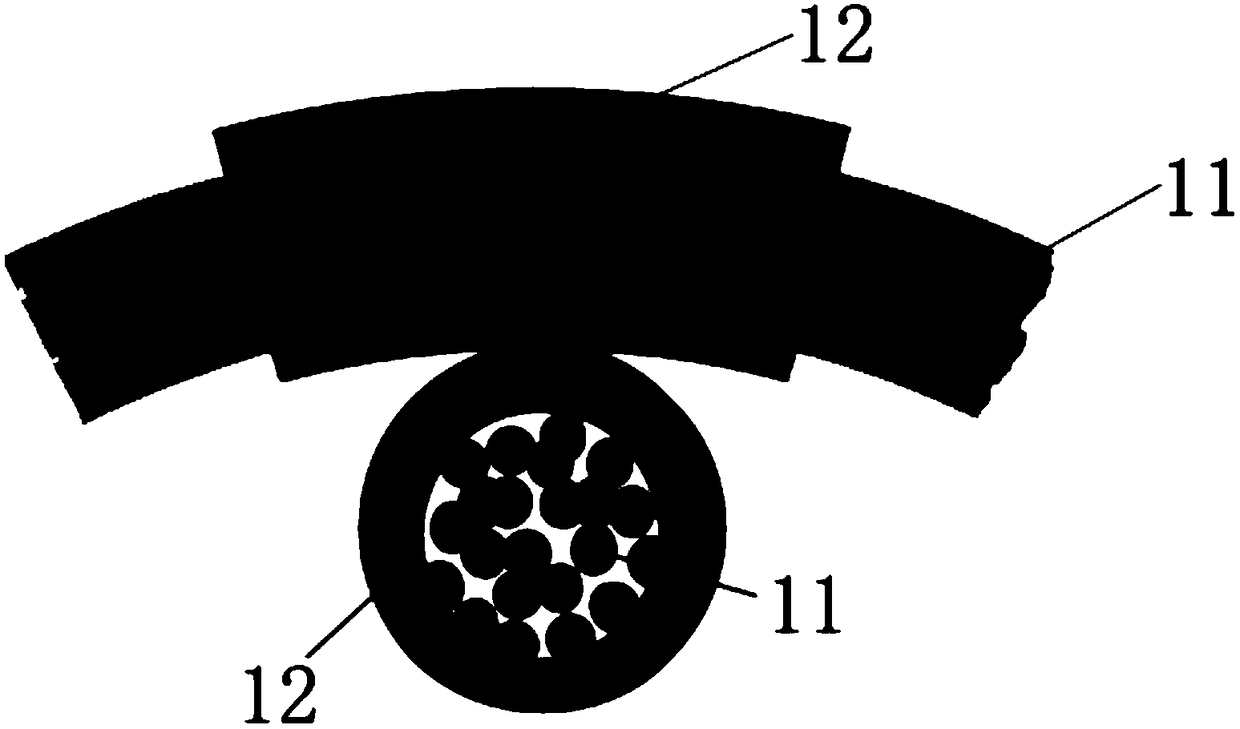

[0027] Further, the conductive fiber 11 may be a metal conductive wire, such as a conductive wire made of gold, silver, or copper, and such a conductive wire material is easy to obtain. Alternatively, the conductive fiber 11 may also be formed by coating the surface of the base fiber with a first conductive material. Wherein, the first conductive material is selected from one of metal nanoparticles, metal nanowires, carbon materials or conductive polymers. The material of the metal nano particles and the metal nano wire is one of gold, silver, copper or zinc. The conductive polymer is selected from one or more of polyaniline, polythiophene, polypyrrole, polyaniline derivative, polythiophene derivative and polypyrrole derivative.

[0028] Further, the matrix fiber ...

Embodiment 1

[0047] The flexible electronic skin capable of sensing pressure provided in this embodiment is manufactured according to the following steps:

[0048] (1) Preparation of conductive fibers: In this implementation, silver nanowires are used as the first conductive material, and silk protein is used as the matrix fiber to prepare conductive fibers. The specific steps are: reducing AgNO with triol 3 The silver nanowire solution is prepared by the method, and the silver nanowire solution is dripped on the surface of the silk fiber, dried at room temperature, and repeated three times to prepare a conductive fiber.

[0049] (2) Preparation of conductive elastomer material: In parts by weight, 3 parts of carbon black material and 30 parts of PDMS prepolymer are mixed at a stirring speed of 100 r / min for 20 minutes to obtain a first mixed solution. Then, 30 parts of the crosslinking agent was added to the first mixed solution and mixed for 3 minutes at a stirring speed of 120 r / min to obtai...

Embodiment 2

[0053] This embodiment provides a flexible electronic skin capable of sensing pressure, which is different from Embodiment 1 in:

[0054] Step (1) Preparation of conductive fibers: In this embodiment, graphene is used as the first conductive material, and silk protein is used as the matrix fiber to prepare conductive fibers. The graphene oxide solution was prepared by the Hummers method, and the solution was configured to be 10 mg / ml, and it was evenly dripped on the surface of the silk fiber, and then the graphene oxide on the surface of the silk fiber was reduced to graphene by hydrazine hydrate steam to obtain conductive fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com