Indoor air sterilizing and purifying filter element material and preparation method

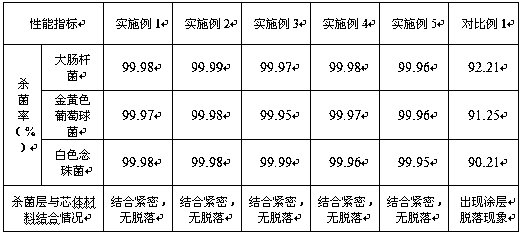

A technology of indoor air and filter elements, applied in the field of air purification, can solve the problems of easy peeling off of the bactericidal coating and unsatisfactory bactericidal effect, and achieve good bactericidal effect, less dosage and excellent bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First, nano titanium dioxide, activated carbon powder, and diatomaceous earth powder are added to the mixed solution of acetic acid and glycerol, and dispersed evenly, then polyacrylonitrile and polyamide are added, and ultrasonic dispersion is formed to form an emulsion, and then electrospinning is carried out. The emulsion was spun into a mesh to obtain a plate-shaped core material; the frequency of ultrasonic dispersion was 42 kHz, and the time was 38 min; the voltage of electrospinning was 16 kV, the advancing speed of the metering pump was 1.3 mL / h, and the receiving distance was 24 cm. The fiber diameter of the fiber web obtained by spinning is 600 nm, and the mesh number is 30 meshes;

[0030] In parts by weight, wherein: 6 parts of nano titanium dioxide, 4 parts of activated carbon powder, 4 parts of diatomaceous earth powder, 17 parts of acetic acid, 37 parts of glycerol, 21 parts of polyacrylonitrile, and 11 parts of polyamide;

[0031] (2) First, add nano...

Embodiment 2

[0037] (1) First, nano titanium dioxide, activated carbon powder, and diatomaceous earth powder are added to the mixed solution of acetic acid and glycerol, and dispersed evenly, then polyacrylonitrile and polyamide are added, and ultrasonic dispersion is formed to form an emulsion, and then electrospinning is carried out. The emulsion was spun into a mesh to obtain a plate-shaped core material; the frequency of ultrasonic dispersion was 48 kHz, and the time was 32 min; the voltage of electrospinning was 19 kV, the advancing speed of the metering pump was 1.8 mL / h, and the receiving distance was 27 cm. The fiber diameter of the fiber web obtained by spinning is 700 nm, and the mesh number is 50 meshes;

[0038] In parts by weight, wherein: 7 parts of nano titanium dioxide, 5 parts of activated carbon powder, 5 parts of diatomaceous earth powder, 22 parts of acetic acid, 25 parts of glycerol, 24 parts of polyacrylonitrile, and 12 parts of polyamide;

[0039](2) First add nano-s...

Embodiment 3

[0045] (1) First, nano titanium dioxide, activated carbon powder, and diatomaceous earth powder are added to the mixed solution of acetic acid and glycerol, and dispersed evenly, then polyacrylonitrile and polyamide are added, and ultrasonic dispersion is formed to form an emulsion, and then electrospinning is carried out. The emulsion was spun into a mesh to obtain a plate-shaped core material; the frequency of ultrasonic dispersion was 46 kHz, and the time was 36 min; the voltage of electrospinning was 17 kV, the advancing speed of the metering pump was 1.5 mL / h, and the receiving distance was 26 cm. The fiber diameter of the fiber web obtained by spinning is 600 nm, and the mesh number is 40 meshes;

[0046] By weight, wherein: 6 parts of nano titanium dioxide, 5 parts of activated carbon powder, 4 parts of diatomaceous earth powder, 19 parts of acetic acid, 32 parts of glycerol, 23 parts of polyacrylonitrile, and 11 parts of polyamide;

[0047] (2) First add nano-silver in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com