High-efficiency multi-stage rotary vane type dynamic liquid film treatment device and treatment method for flue gas

A rotary vane-type, high-efficiency technology, applied in the field of flue gas treatment, can solve the problems of large volume and investment, and achieve the effects of high treatment efficiency, thorough treatment and long treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

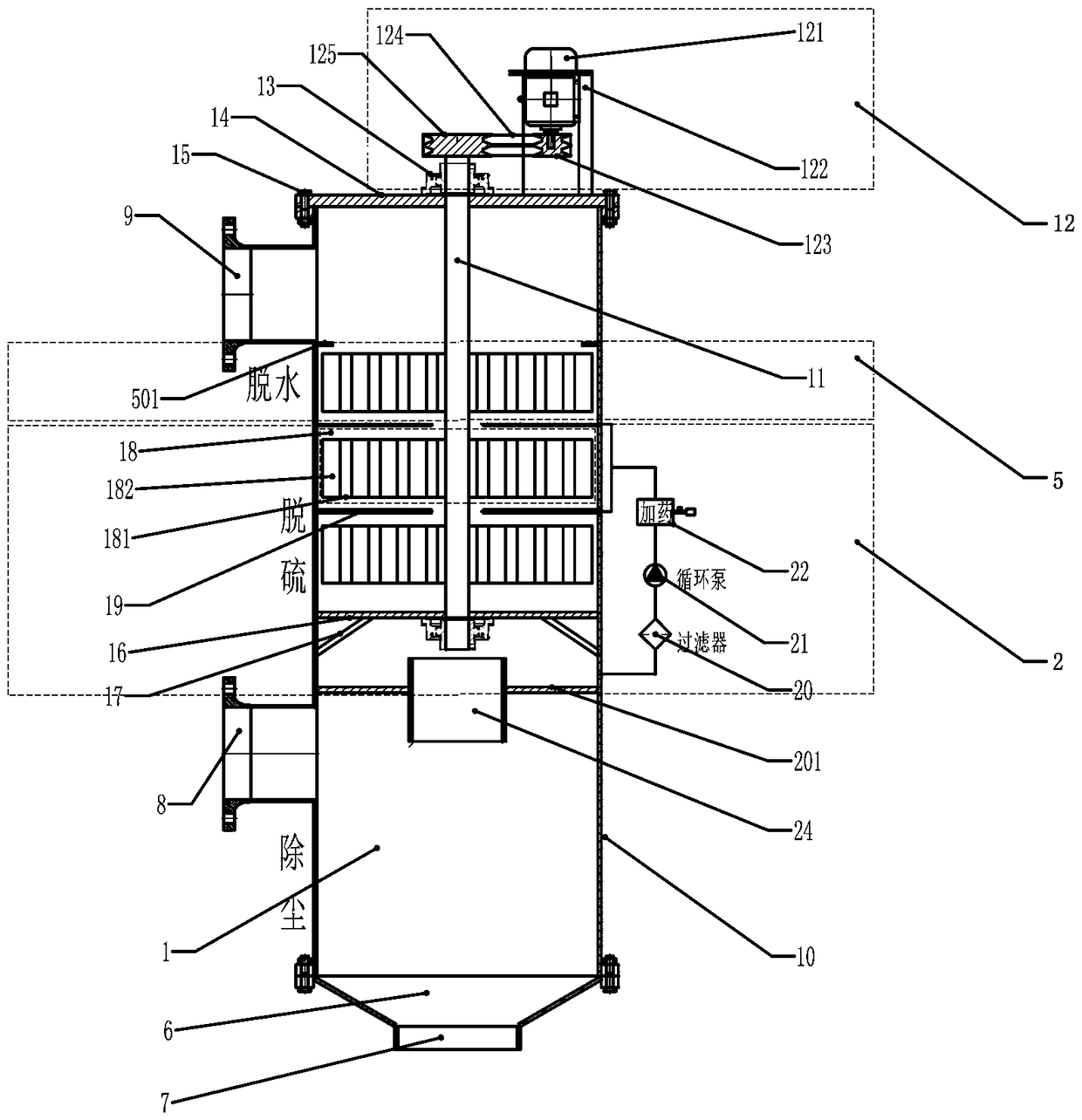

Embodiment 1

[0044] Embodiment 1, the high-efficiency multi-stage rotary vane type dynamic liquid film treatment flue gas device includes a cylindrical tower body (10) and a central rotating shaft (11), the top of the tower body (10) is provided with a cover plate (14), and the cover plate ( 14) It is fixed on the top of the tower body (10) through the flange (15), and the cover plate (14) is provided with a bearing seat (13) and a frequency conversion drive (12), and the frequency conversion drive (12) drives the central shaft (11) rotation; the variable frequency drive (12) consists of a variable frequency motor (121), a motor bracket (122), a motor V-belt pulley (123), a shaft V-belt pulley (125) and a V-belt (124), and the motor bracket ( 122) is fixed on the cover plate (14), the variable frequency motor (121) is fixed on the motor bracket (122), the shaft V-belt pulley (125) is connected with the central rotating shaft (11), and the motor V-belt pulley of the variable frequency motor ...

Embodiment 2

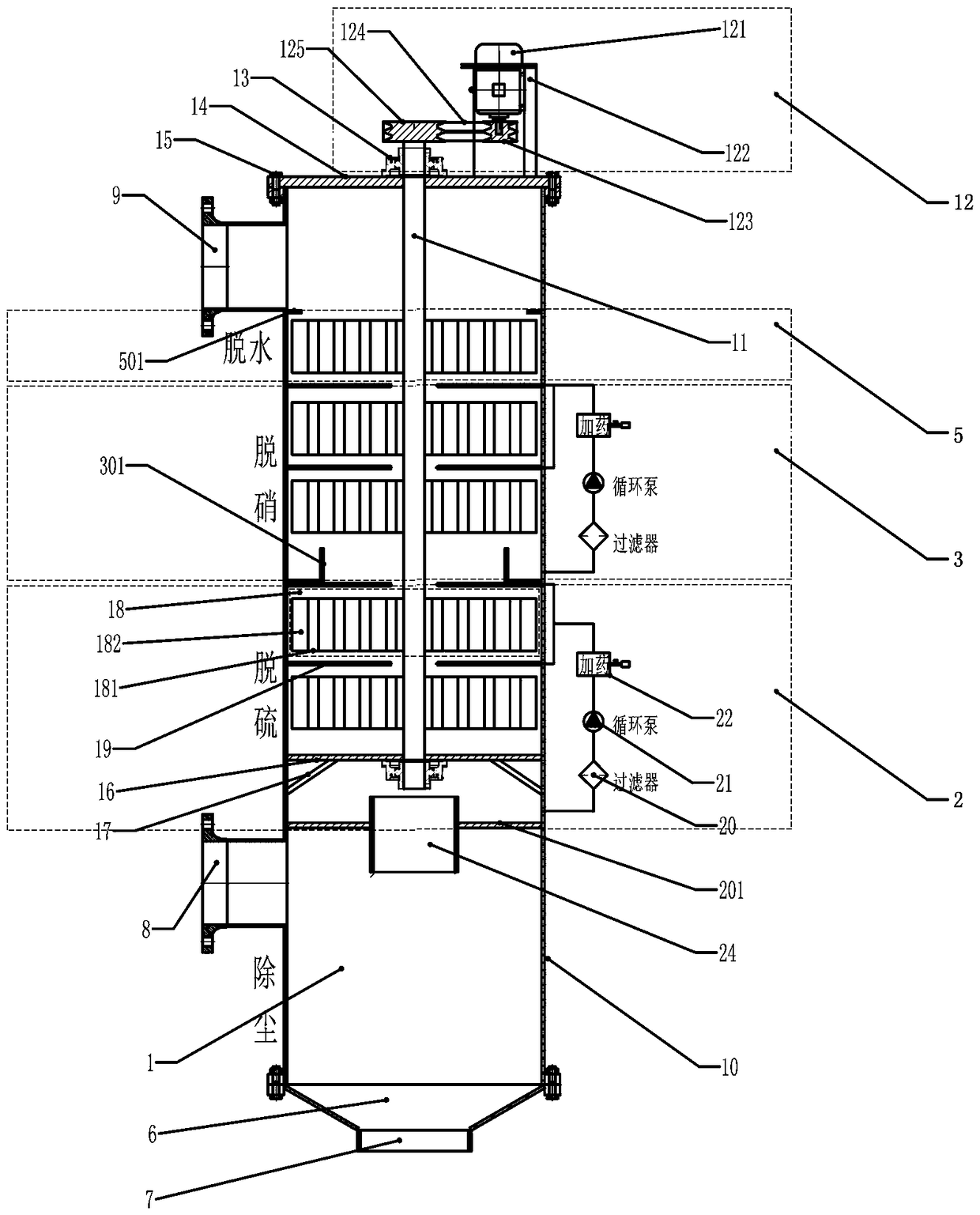

[0047] Embodiment 2, compared with Embodiment 1, a denitrification zone (3) is added, the denitrification zone (3) is set above the desulfurization zone (2), and there are at least two upper and lower levels in the denitrification zone (3). The same rotary vane device (18), each stage of the rotary vane device (18) in the denitrification zone (3) is also located on the central rotating shaft (11), and each stage of the rotary vane device (18) in the denitrification zone (3) ) and the inner wall of the tower body (10), there is a certain gap between the top of each stage of the rotary vane device (18) in the denitrification zone (3). The lower part of the leaf device (18) is provided with an annular denitrification water receiving tank (301) closely connected with the inner wall of the tower body (10), and the annular denitrification water receiving tank (301) is adjacent to the spray pipe (19 ), and above the spray pipe (19) of the desulfurization zone (2); the ring-shaped den...

Embodiment 3

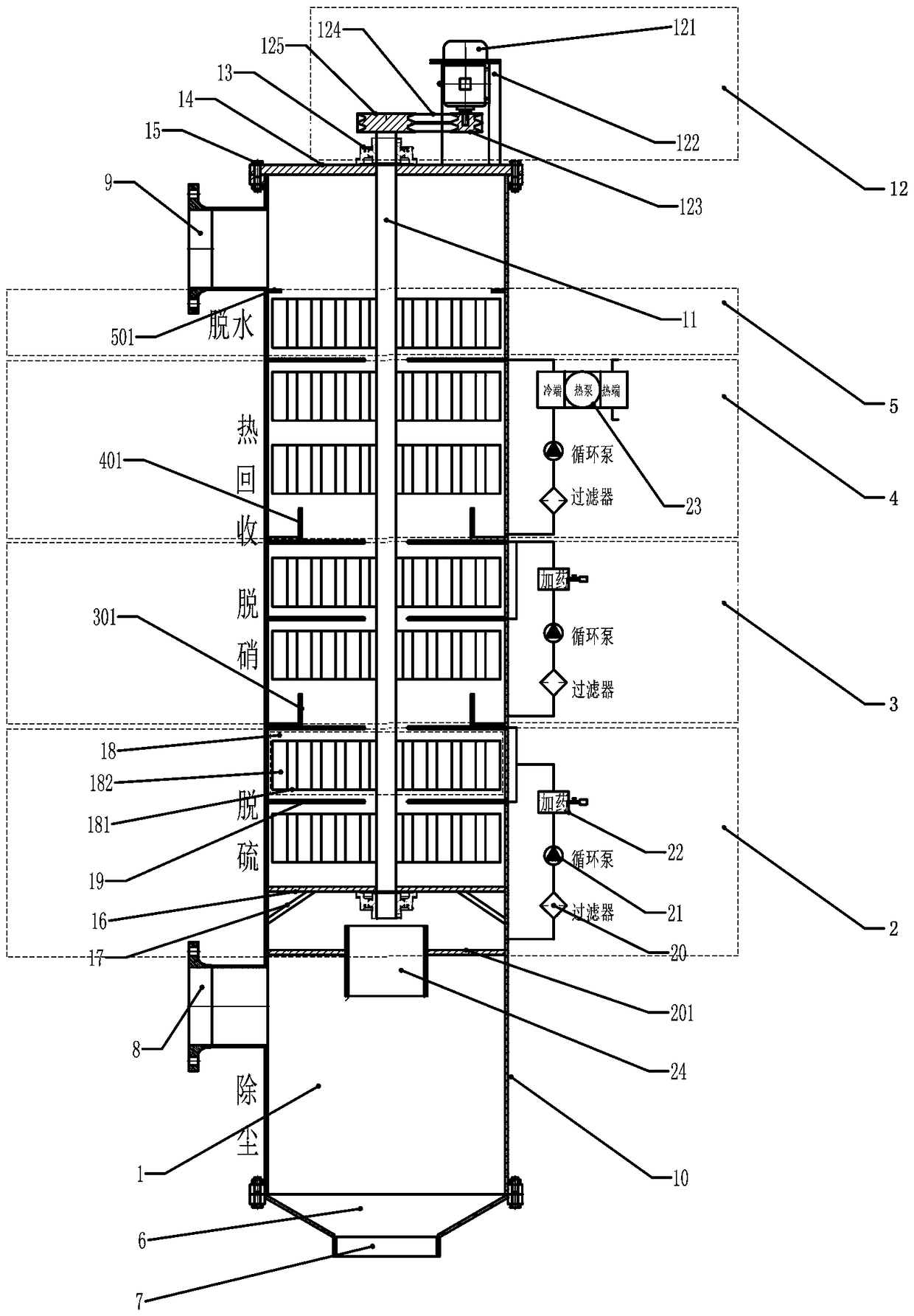

[0049] Embodiment 3, compared with Embodiment 1 or Embodiment 2, a heat recovery zone (4) is added, the heat recovery zone (4) is set above the desulfurization zone (2) or the denitrification zone (3), and the heat recovery zone (4 ) is equipped with at least two stages of rotary vane devices (18) that are the same as those in Embodiment 1, and each stage of rotary vane devices (18) in the heat recovery zone (4) is also arranged on the central shaft (11). There is a certain gap between the outermost periphery of each stage of the rotary vane device (18) in the recovery area (4) and the inner wall of the tower body (10), and above each stage of the rotary vane device (18) in the heat recovery area (4). The spray pipe (19), the lower rotary vane device (18) of the heat recovery area (4) is provided with an annular heat exchange receiving tank (401) tightly connected to the inner wall of the tower, and the annular heat exchange receiving tank (401) is adjacent to the spray pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com