Method for preparing gel ball

A gel ball and coagulator technology, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of inaccurate flow rate control, influence of mechanical strength and adsorption performance, large difference in diameter of gel balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

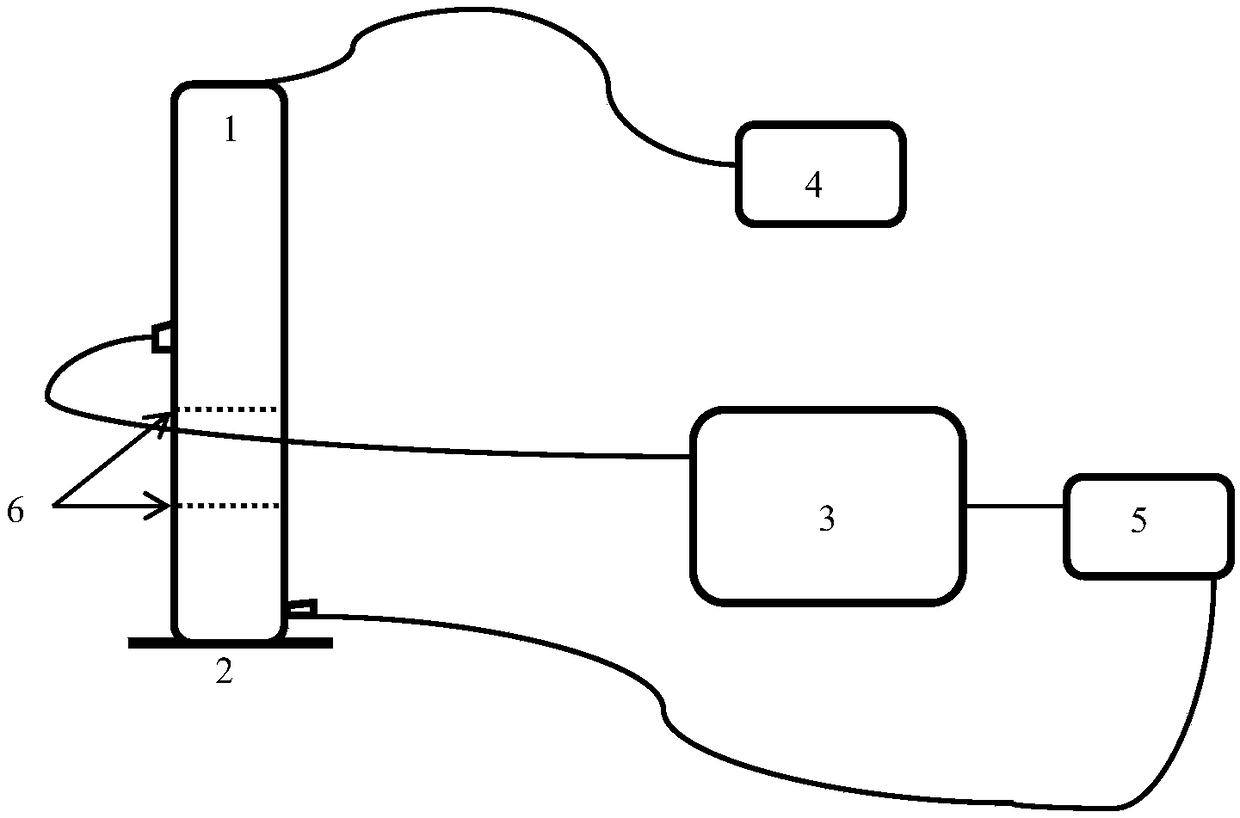

Method used

Image

Examples

Embodiment 1

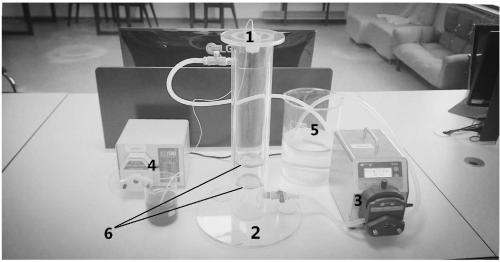

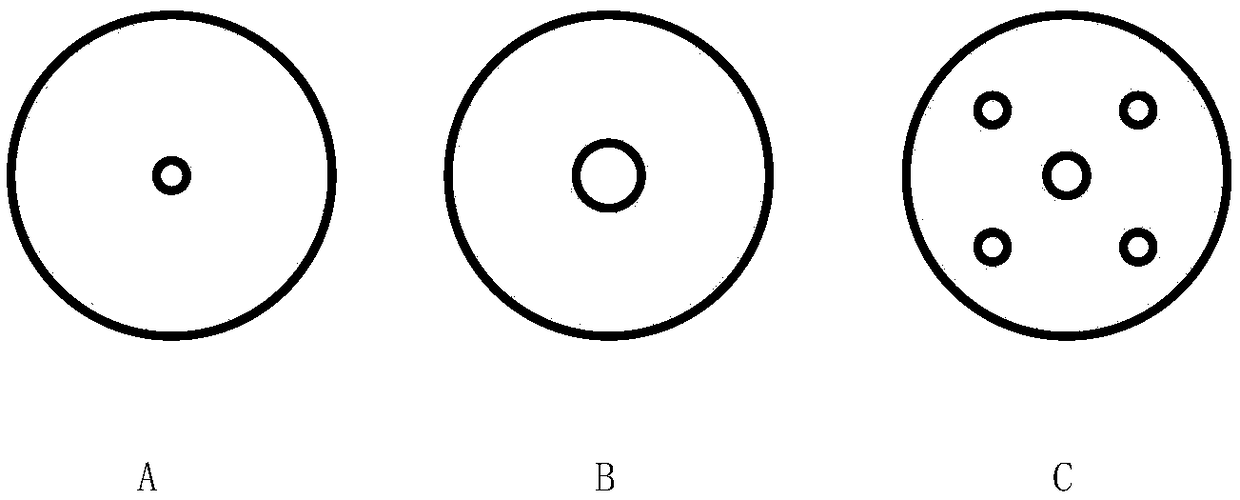

[0027] Use a single-hole drip injector with an aperture of Φ1mm to prepare gel beads for immobilizing keratinase; the pump ① uses a high-performance liquid chromatography pump; the coagulator uses an outer sleeve with an outer diameter of 100mm, a thickness of 10mm, and a height of 50cm; the inner sleeve The outer diameter of the cylinder is 88mm, the thickness is 5mm, and the height is 10cm. There are three separators, with two sorters, the upper separator has a stainless steel screen of 4 mesh, and the lower separator has a stainless steel screen of 10 mesh; the cross-linking agent storage uses a glass beaker; Pump ② chooses ordinary peristaltic pump. The polymer material solution is selected from 0.5%wt sodium alginate solution (i.e. 0.5g sodium alginate is dissolved in 100ml water), and the cross-linking agent is 0.6%wt calcium chloride solution (i.e. 0.6g calcium chloride is dissolved in 100ml water) . The flow rate of pump ① is 1mL / min, and the flow rate of pump ② is 5m...

Embodiment 2

[0042] Use a five-hole drip injector with a pore diameter of Φ50dmm to prepare gel beads for the adsorption of heavy metal ions; the pump ① uses a high-speed countercurrent chromatography pump; the coagulator uses an outer sleeve with an outer diameter of 100mm, a thickness of 10mm, and a height of 50cm; the inner sleeve The outer diameter is 88mm, the thickness is 5mm, and the height is 10cm3. There are two sorters, the upper classifier has a stainless steel screen of 10 mesh, and the lower classifier has a stainless steel screen of 20 mesh; the cross-linking agent storage uses a glass beaker; the pump② Use ordinary peristaltic pumps. The polymer material solution is selected 4%wt sodium alginate solution (i.e. 4g sodium alginate is dissolved in 100ml water) and 1%wt chitosan solution, and cross-linking agent adopts 0.2%wt calcium chloride solution (i.e. 0.2g Calcium chloride dissolved in 100ml of water). Sodium alginate-chitosan composite gel beads with uniform size and hig...

Embodiment 3

[0044] A coaxial double hole drip injector was used to prepare gel beads; two high performance liquid chromatography pumps were selected to supply liquid to the outer hole and the inner hole of the drip injector respectively, and the outer hole provided 0.5%wt chitosan solution, and the inner hole Provide 0.5%wt sodium alginate solution; the coagulator adopts three outer sleeves with an outer diameter of 100mm, a thickness of 10mm, and a height of 50cm; an inner sleeve with an outer diameter of 88mm, a thickness of 5mm, and a height of 10cm. The stainless steel screen of the upper classifier is 4 mesh, and the stainless steel screen of the lower classifier is 10 mesh; the crosslinking agent storage is a glass beaker, and the crosslinking agent is 0.6%wt calcium chloride solution. It can prepare shell-core structure double-layer pellets with uniform size and high mechanical strength. The average particle size of the pellets is 2 mm. Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com