Treatment method for high-salt and high-COD (chemical oxygen demand) wastewater

A treatment method and wastewater technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high energy consumption and high production cost, reduce energy consumption, reduce environmental protection pressure, The effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

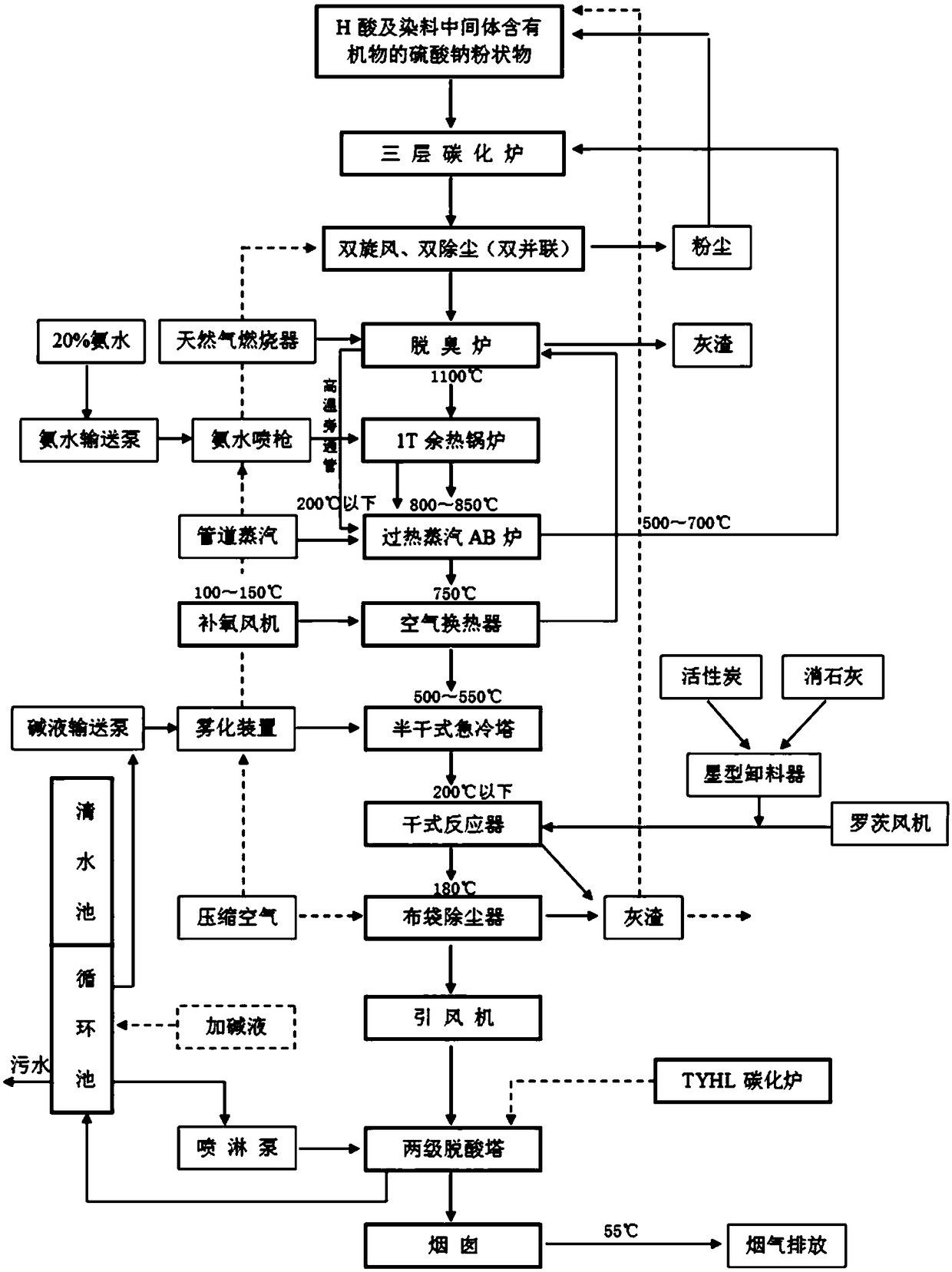

[0044] This embodiment is a treatment method for high-salt and high-COD wastewater, wherein the high-salt and high-COD wastewater is the wastewater produced in the regeneration production of dye intermediates and dilute acids, including disperse dye wastewater, H acid wastewater, sodium chloride solution, sulfuric acid Sodium solution or para-ester wastewater, the present embodiment selects para-ester wastewater, including the following steps:

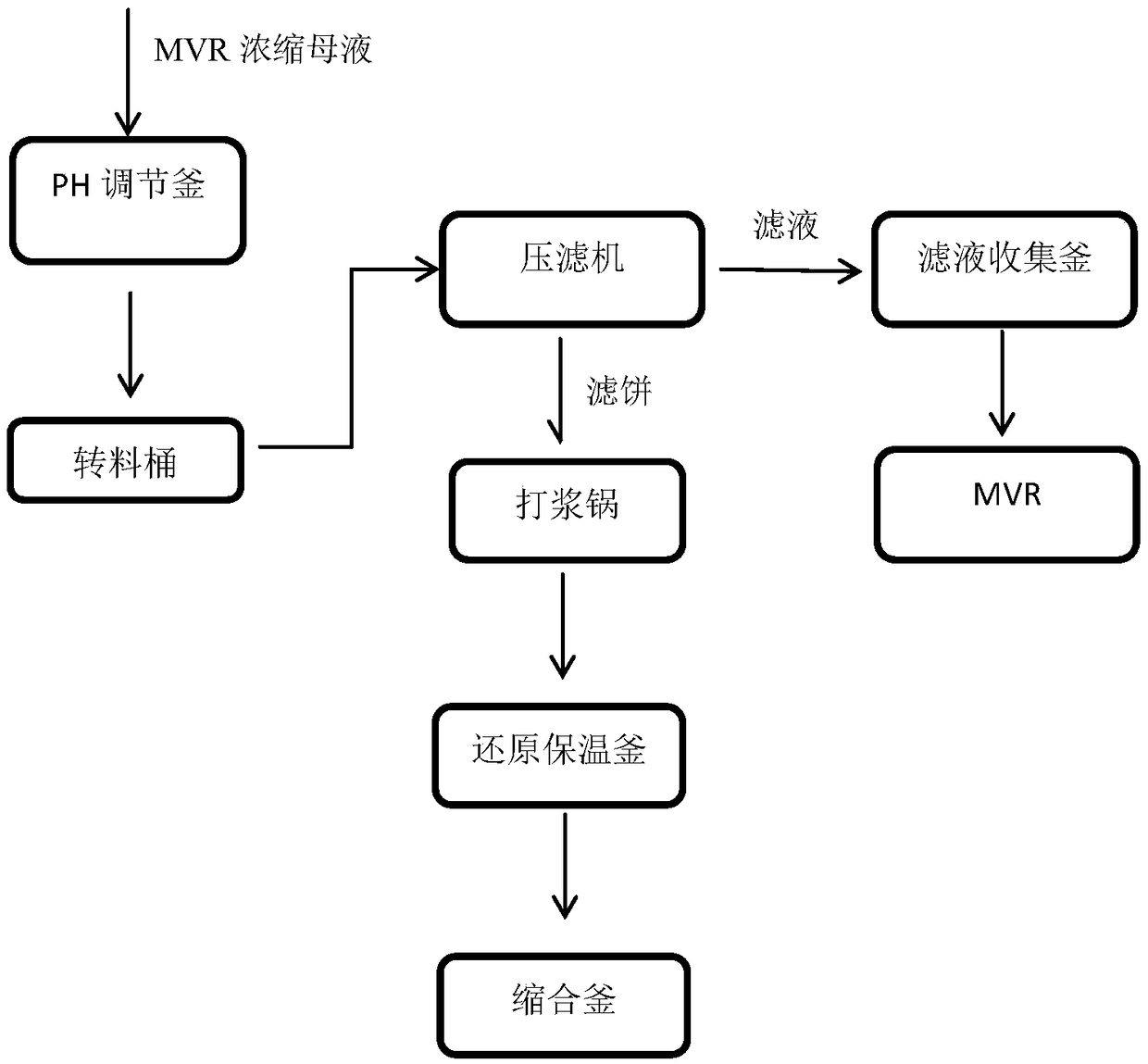

[0045] (1) Concentrate high-salt and high-COD wastewater by MVR distillation and spray drying to form powder:

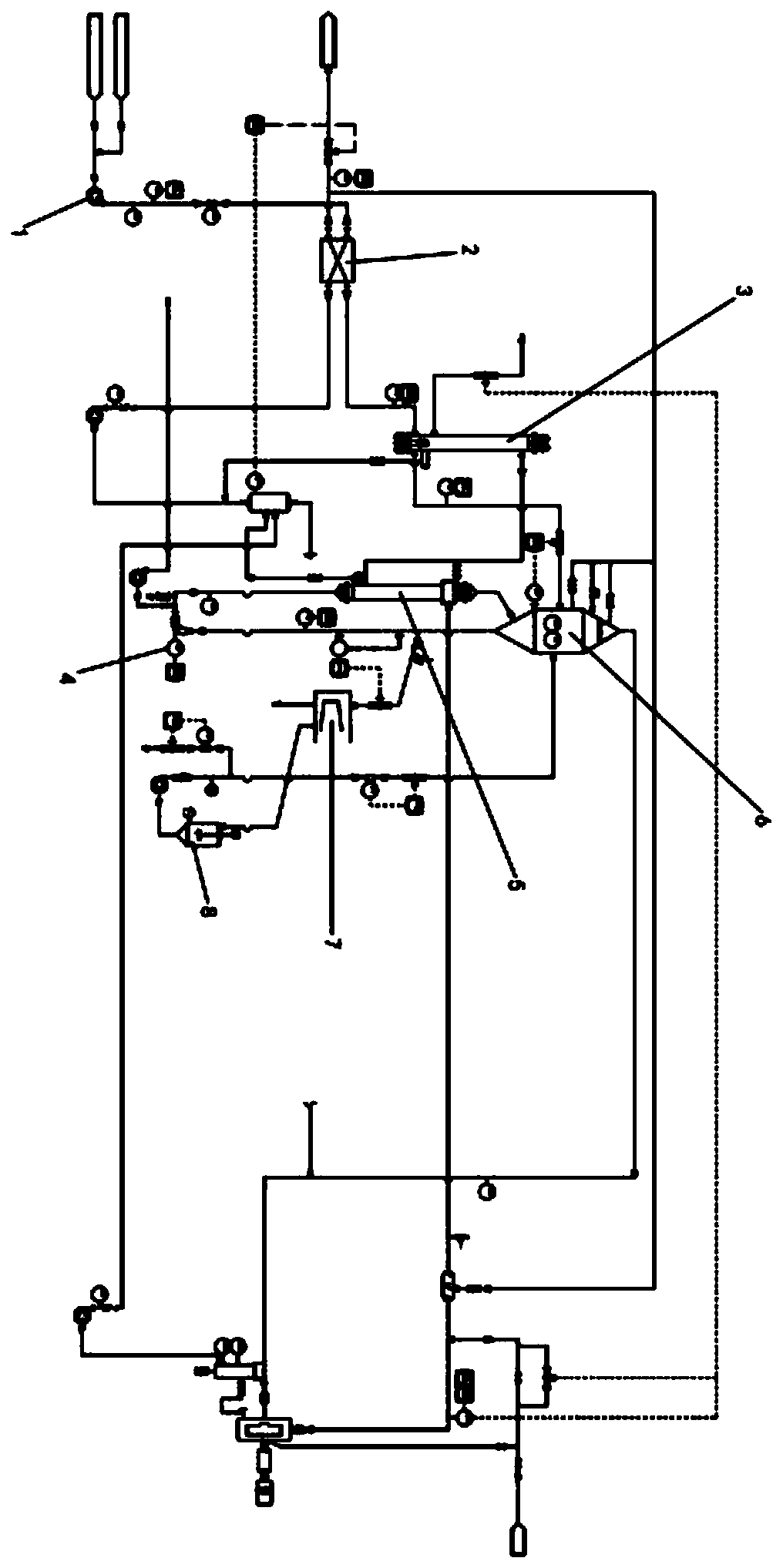

[0046] as attached figure 1 As shown, the waste water in this embodiment is pressurized by the feed pump 1 and firstly enters the first plate-type preheater 2, conducts heat exchange with the condensed water generated by the system and heats it to 95-98°C, and then enters the second tube-type preheater The device exchanges heat with the non-condensable gas.

[0047]The material preheated twice enters the crystallizer 6 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com