UV-PU dual-curing 3D printing resin and preparation method and application thereof

A dual-curing, resin technology, applied in the field of 3D printing materials, can solve the problems of high shrinkage, increased viscosity, limited use, etc., and achieve the effect of improving the degree of reaction, reducing shrinkage, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

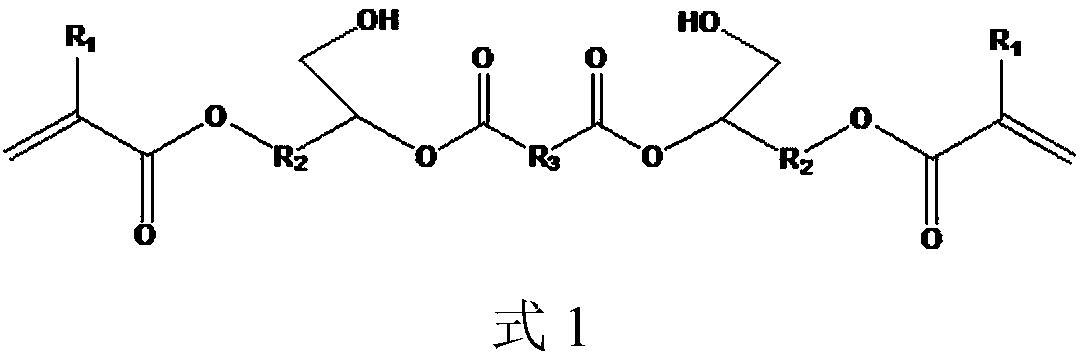

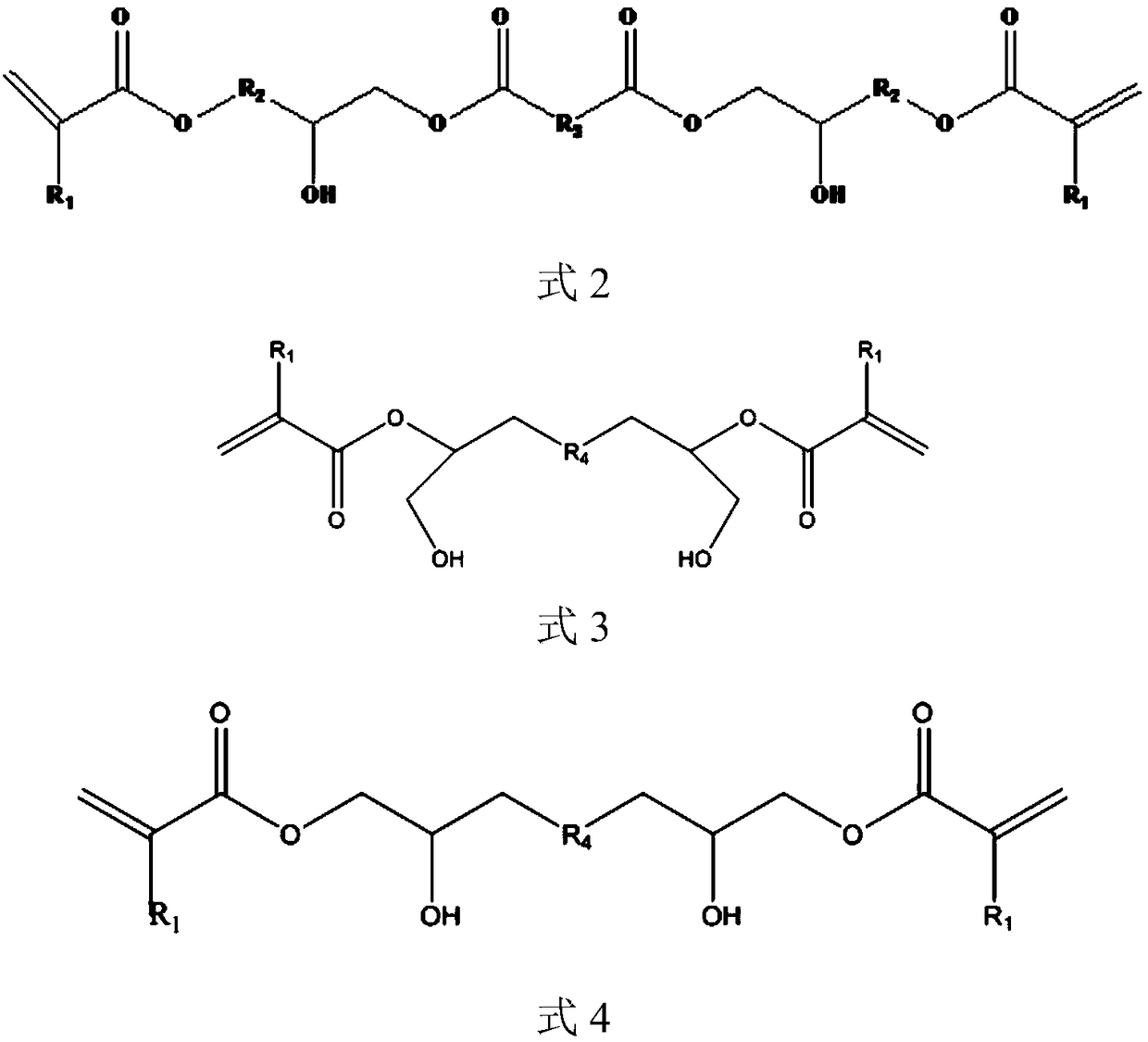

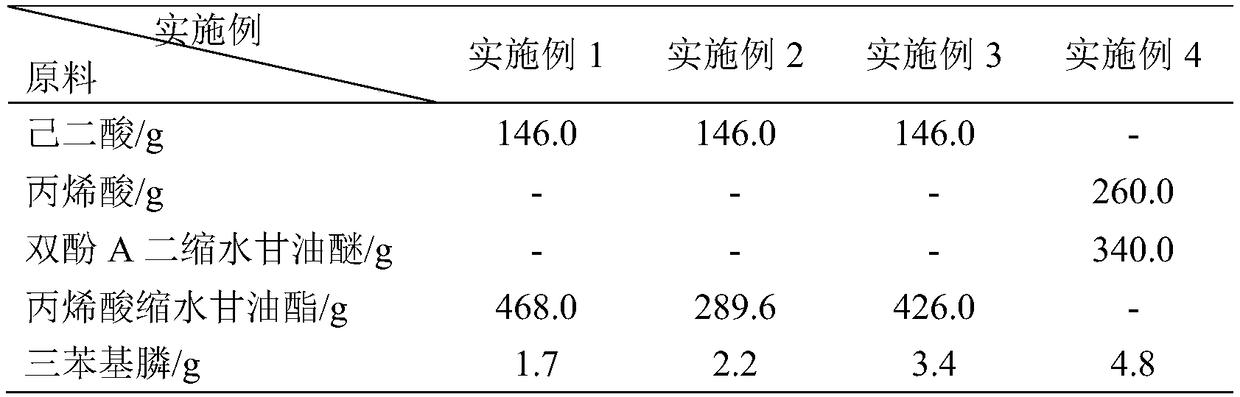

[0021] 1. Add organic acid, epoxy monomer, catalyst and polymerization inhibitor according to Table 1 in a 500ml four-necked flask with mechanical stirring, temperature control thermocouple and condenser. Heat and stir, keep the temperature at 80°C until the system becomes transparent, raise the temperature to 100°C, and continue the reaction until the acid value is lower than 20-10mgKOH / g. The prepolymer is at least one of formula 1 to formula 4.

[0022] 2. According to Table 2, take the above-mentioned prepolymer in a beaker, add photoinitiator, diluent and curing agent in another beaker, keep away from light and stir until the photoinitiator is completely dissolved, pour it into the prepolymer, avoid Stir until it is transparent and uniform, and prepare the resin for later use.

[0023] 3. Use a laser stereolithography (SLA) 3D printer to print out a standard tensile test sample according to the ISO527 standard. The samples were baked in an oven at 120°C for 2h.

[0024...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com