A pe grass-proof ground cloth with long-term anti-aging function

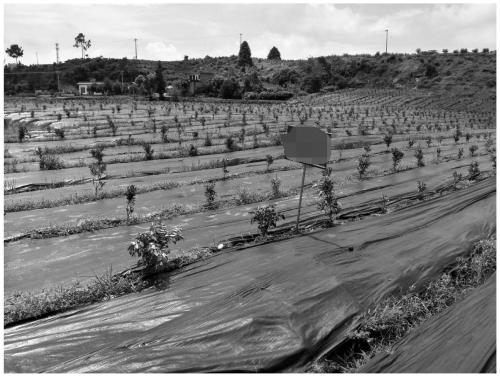

An anti-aging and grassland technology, which is applied in the fields of agriculture and horticulture, can solve the problems of poor anti-aging performance of plastic film, high labor cost of agricultural film, short service life and other problems, and achieve strong weather resistance, shorten the growth cycle and ensure the inhibition effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

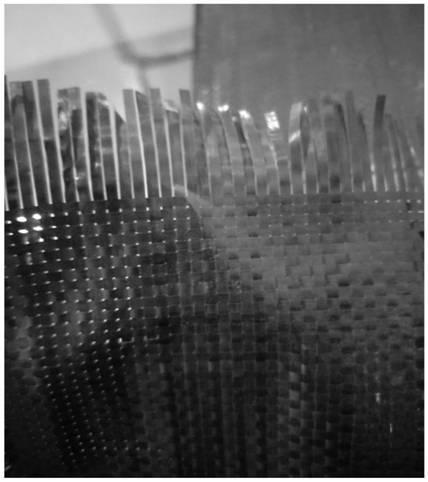

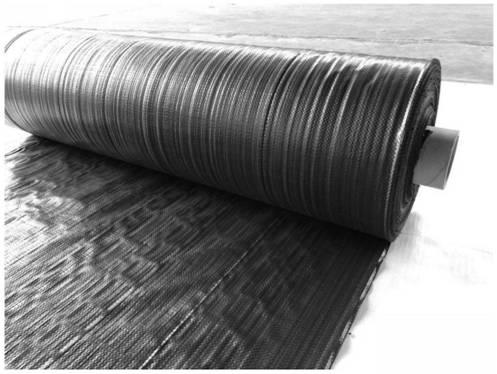

Image

Examples

Embodiment 1

[0029] This embodiment provides a PE anti-grass cloth with long-term anti-aging function. Calculated by mass percentage, the raw material composition of the PE anti-grass cloth is:

[0030] 85% polyethylene, 5% color masterbatch, 5% anti-aging additives, 5% filler masterbatch.

[0031] The raw material composition of color masterbatch is: polyethylene 15%, polyethylene wax 25%, carbon black 30%, calcium carbonate 30%.

[0032] The raw material composition of the anti-aging auxiliary agent is: 77.5% of polyethylene, 20% of light stabilizer, 2% of antioxidant, and 0.5% of lubricant. The light stabilizer is LS770; the antioxidant is a mixture of antioxidant 1010 and antioxidant CA in a mass ratio of 1:1; the lubricant is glyceryl stearate.

[0033] The raw material composition of the filler masterbatch is: calcium carbonate 82%, coupling agent 1%, dispersant 1%, lubricant 4%, polyethylene 12%. The coupling agent is KH560; the dispersant is ethylene-acrylic acid copolymer; the l...

Embodiment 2

[0035] This embodiment provides a PE anti-grass cloth with long-term anti-aging function. Calculated by mass percentage, the raw material composition of the PE anti-grass cloth is:

[0036] 90% polyethylene, 4% color masterbatch, 3% anti-aging additives, 3% filler masterbatch.

[0037] The raw material composition of color masterbatch is: polyethylene 15%, polyethylene wax 25%, carbon black 30%, calcium carbonate 30%.

[0038] The raw material composition of the anti-aging auxiliary agent is: 77.5% of polyethylene, 20% of light stabilizer, 2% of antioxidant, and 0.5% of lubricant. The light stabilizer uses N539; the antioxidant uses antioxidant TNP; the lubricant uses polyethylene wax.

[0039] The raw material composition of the filler masterbatch is: calcium carbonate 82%, coupling agent 1%, dispersant 1%, lubricant 4%, polyethylene 12%. The coupling agent is a mixture of SCA1503 and KH560 at a mass ratio of 1:1; the dispersant is ethylene-acrylic acid copolymer; the lubri...

Embodiment 3

[0041] This embodiment provides a PE anti-grass cloth with long-term anti-aging function. Calculated by mass percentage, the raw material composition of the PE anti-grass cloth is:

[0042] 87% polyethylene, 5% color masterbatch, 4% anti-aging additives, 4% filler masterbatch.

[0043] The raw material composition of color masterbatch is: polyethylene 15%, polyethylene wax 25%, carbon black 30%, calcium carbonate 30%.

[0044] The raw material composition of the anti-aging auxiliary agent is: 77.5% of polyethylene, 20% of light stabilizer, 2% of antioxidant, and 0.5% of lubricant. The light stabilizer is a mixture of LS770 and N539 in a mass ratio of 2:1; the antioxidant is a mixture of antioxidant 1010, antioxidant CA and antioxidant TNP in equal parts by mass; the lubricant is glyceryl stearate and Polyethylene wax is a 1:1 mixture by mass.

[0045] The raw material composition of the filler masterbatch is: calcium carbonate 82%, coupling agent 1%, dispersant 1%, lubricant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com