Hemostyptic microsphere containing antibacterial ingredient berberine as well as preparation method and application of hemostyptic microsphere

An antibacterial ingredient, berberine technology, applied in hemostatic microspheres containing antibacterial ingredient berberine and its preparation and application fields, can solve the problems of being difficult to degrade and absorb, and not suitable for hemostatic powder, so as to achieve convenient use and shorten hemostasis time , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

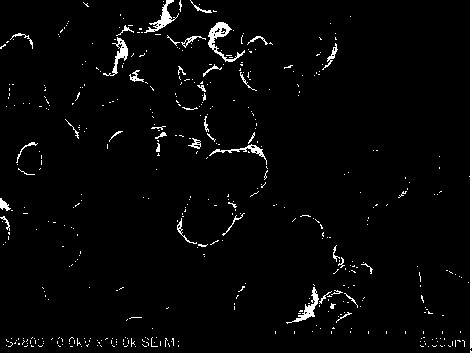

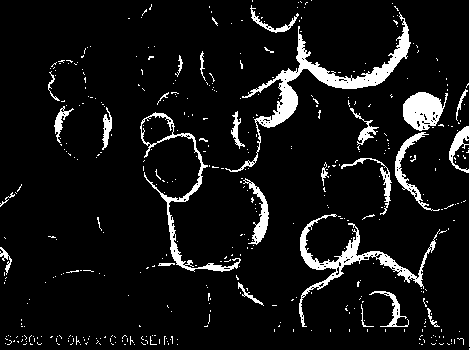

Image

Examples

Embodiment 1

[0038] 1. Preparation of matrix solution: Add 15 g of sodium alginate, 10 g of sodium carboxymethylcellulose and 0.25 g of gelatin to 1000 ml, 500 ml, and 500 ml of water and stir to dissolve, then mix the three solutions to make a matrix solution .

[0039] 2. Material mixing and emulsification cross-linking copolymerization: 2000 ml ddH 2 O was added to the beaker, and then 187.5 ml of Tween 80 was added, stirred rapidly for about 5 minutes, then the matrix solution was added, and emulsified and stirred for 30 minutes. After emulsification, slowly add 2% CaCl dropwise 2 Solution 10 ml, for cross-linking reaction, after dropwise stirring for 1 h. After the cross-linking is completed, add 5000ml of absolute ethanol to soak for 2 h.

[0040] 3. Refining: After the solution is separated, discard the lower layer solution, filter with suction, wash the crude sample 3 times with 1000 ml absolute ethanol, and then wash 3 times with 1000 ml petroleum ether. The eluted sample was ...

Embodiment 2

[0042] 1. Preparation of matrix solution: Add 15 g of sodium alginate, 10 g of sodium carboxymethylcellulose and 0.25 g of gelatin to 1000 ml, 500 ml, and 500 ml of water and stir to dissolve, then mix the three solutions to make a matrix solution .

[0043] 2. Material mixing and emulsification cross-linking copolymerization: 2000 ml ddH 2 O was added to the beaker, and then 187.5 ml of Tween 80 was added, stirred rapidly for about 5 minutes, then the matrix solution was added, and emulsified and stirred for 30 minutes. After emulsification, slowly add 2% CaCl dropwise 2 Solution 10 ml, for cross-linking reaction, after dropwise stirring for 1 h. After the cross-linking is completed, add 5000ml of absolute ethanol to soak for 2 h.

[0044] 3. Refining: After the solution is separated, discard the lower layer solution, filter with suction, wash the crude sample 3 times with 1000 ml absolute ethanol, and then wash 3 times with 1000 ml petroleum ether. Dissolve the eluted sa...

Embodiment 3

[0046] 1. Preparation of matrix solution: Add 15 g of sodium alginate, 10 g of sodium carboxymethylcellulose and 0.25 g of gelatin to 1000 ml, 500 ml, and 500 ml of water and stir to dissolve, then mix the three solutions to make a matrix solution .

[0047] 2. Material mixing and emulsification cross-linking copolymerization: 2000 ml ddH 2 O was added to the beaker, and then 187.5 ml of Tween 80 was added, stirred rapidly for about 5 minutes, then the matrix solution was added, and emulsified and stirred for 30 minutes. After emulsification, slowly add 2% CaCl dropwise 2 Solution 10 ml, for cross-linking reaction, after dropwise stirring for 1 h. After the cross-linking is completed, add 5000ml of absolute ethanol to soak for 2 h.

[0048] 3. Refining: After the solution is separated, discard the lower layer solution, filter with suction, wash the crude sample 3 times with 1000 ml absolute ethanol, and then wash 3 times with 1000 ml petroleum ether. The eluted sample was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com