Heat-vulcanized quickly-formed rubber

A thermal vulcanization and rapid technology, which is applied in the field of rubber production for automobiles, can solve the problems of high temperature resistance, low ozone resistance, difficulty in meeting high performance requirements, long thermal vulcanization time, etc., to improve anti-aging , prolong the anti-aging time, reduce the effect of scorching phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

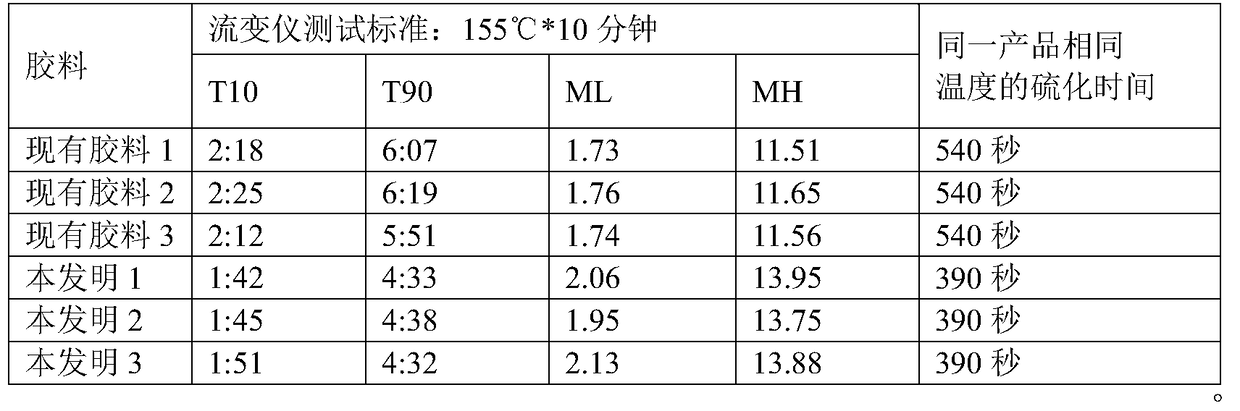

Examples

Embodiment 1

[0033] A thermally vulcanized rapid prototyping rubber, made by mixing the following components: 80kg of natural rubber (SVR3L), 20kg of butadiene rubber (butadiene rubber 9000), 5kg of zinc oxide, 2kg of stearic acid, 3kg of microcrystalline wax, Guma Long resin 3kg, coupling agent (silane coupling agent Si-69) 2kg, flow aid (model ADDITEK-222, Taikai Chemical) 3kg, softener (No. 46 engine oil) 8kg, carbon black mixture 78kg, anti-aging Agent mixture 4kg, accelerator mixture 1kg, vulcanizing agent (sulfur) 2.2kg, anti-scorch agent (CTP-80) 0.2kg.

[0034] The carbon black mixture is a mixture of carbon black 330 and carbon black 774, and the weight ratio of the two is carbon black 330: carbon black 774 = 50: 30.

[0035] The antiaging agent mixture is a mixture of antiaging agent RD and antiaging agent 4010NA, and the weight ratio of the two is antiaging agent RD:antiaging agent 4010NA=2:3.

[0036]The accelerator mixture is a mixture of accelerator CZ, accelerator DM and ac...

Embodiment 2

[0047] A thermally vulcanized rapid prototyping rubber, made by mixing the following components: 70kg of natural rubber (SVR3L), 30kg of butadiene rubber (butadiene rubber 9000), 6kg of zinc oxide, 1.5kg of stearic acid, 2kg of microcrystalline wax, ancient Malone resin 5kg, coupling agent (silane coupling agent Si-69) 3kg, flow aid (model ADDITEK-222, Taikai Chemical) 4kg, softener (No. 46 engine oil) 7kg, carbon black mixture 75kg, Aging agent mixture 7kg, accelerator mixture 1.3kg, vulcanizing agent (sulfur) 1.8kg, anti-scorch agent (CTP-80) 0.3kg.

[0048] Described carbon black mixture is the mixture of carbon black 330 and carbon black 774, and the weight ratio of the two is carbon black 330: carbon black 774=60:20.

[0049] The antiaging agent mixture is a mixture of antiaging agent RD and antiaging agent 4010NA, and the weight ratio of the two is antiaging agent RD:antiaging agent 4010NA=3:2.

[0050] The accelerator mixture is a mixture of accelerator CZ, accelerator...

Embodiment 3

[0061] A thermally vulcanized rapid prototyping rubber, made by mixing the following components: 90kg of natural rubber (SVR3L), 10kg of butadiene rubber (butadiene rubber 9000), 8kg of zinc oxide, 1kg of stearic acid, 4kg of microcrystalline wax, Guma Long resin 4kg, coupling agent (silane coupling agent Si-69) 1kg, flow aid (model ADDITEK-222, Taikai Chemical) 2kg, softener (No. 46 engine oil) 5kg, carbon black mixture 80kg, anti-aging Agent mixture 5.5kg, accelerator mixture 1.5kg, vulcanizing agent (sulfur) 2.5kg, anti-scorch agent (CTP-80) 0.1kg.

[0062] Described carbon black mixture is the mixture of carbon black 330 and carbon black 774, and the weight ratio of the two is carbon black 330: carbon black 774=55:25.

[0063] The antiaging agent mixture is a mixture of antiaging agent RD and antiaging agent 4010NA, and the weight ratio of the two is antiaging agent RD:antiaging agent 4010NA=2.5:2.5.

[0064] The accelerator mixture is a mixture of accelerator CZ, acceler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com