Oxygen vacancy dominated CuO/ZnFe2O4 core-shell structure microsphere-based xylene gas sensor and preparation method thereof

A technology of gas sensor and core-shell structure, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve problems such as people's health and life threats, and achieve the effects of fast response recovery, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

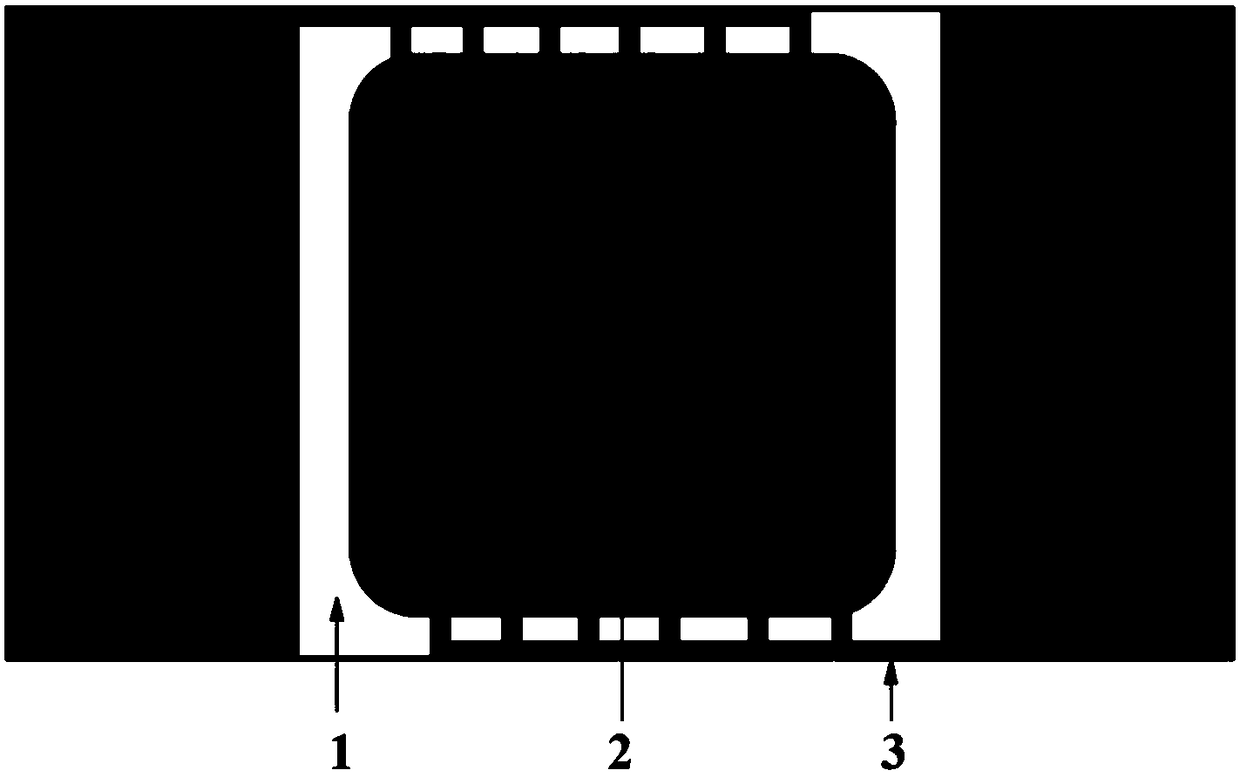

[0040] 1. Treatment of Pd metal finger electrodes

[0041] First, use acetone and ethanol cotton balls to wipe the Al with Pd metal inter-finger electrodes (prepared by screen printing technology). 2 o 3 substrate, and then Al with Pd metal interfinger electrodes 2 o 3 The substrate was placed in acetone, ethanol and deionized water in turn, ultrasonically cleaned for 10 minutes, and finally dried at 100 °C;

[0042] The present invention uses screen printing technology on Al 2 o 3 Prepare Pd metal finger electrodes on the substrate, the specific method is as follows: mix ink [Jiahua JX07500487]: Pd powder: diluent at a mass ratio of 1:1:2, stir to make a paste; then inject the paste into On the screen plate with the pattern of the inserted finger electrode, scrape the paste at an inclination angle of 30° and a pressure of 5 Newtons, in Al 2 o 3 The electrode is printed on the substrate and dried, and the preparation of the Pd metal finger electrode is completed after u...

Embodiment 2

[0054] The sensitivity is 16.3 (100ppm xylene);

[0055] The response time is 15 seconds and the recovery time is 6 seconds.

Embodiment 3

[0057] The sensitivity is 23.7 (100ppm xylene);

[0058] The response time was 27 seconds and the recovery time was 14 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com