Cathode material of lithium battery and preparation method thereof

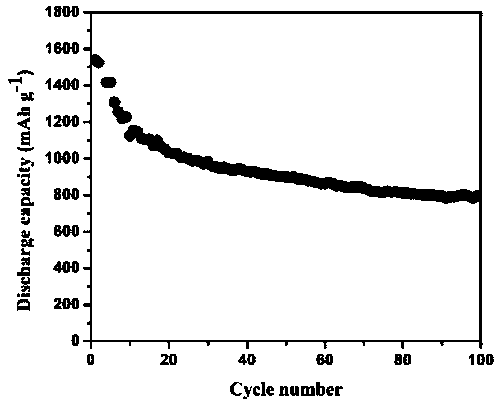

A negative electrode material, technology of lithium ion battery, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance and rate performance, loss of active material of lithium battery, low utilization rate of sulfur cathode, etc., to achieve cycle stability Improved, excellent cycle stability, high discharge capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] Step 1: Preparation of Ni-ZIF-67@CC / CNTS composite:

[0024] 1400mg of Co(NO 3 ) 2 ·6H 2 O was added to 200ml of anhydrous methanol and stirred; 1600mg of 2-methylimidazole was added to 200ml of anhydrous methanol and stirred, and the solution mixed with 2-methylimidazole was slowly poured into the still stirring Co(NO 3 ) 2 ·6H 2 O solution and add a little carbon cloth, stir for 30min and let stand. After 24 h the solution was centrifuged and dried. Take 350mgNi(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of absolute ethanol, and the prepared ZIF-67 / CC was added to the above solution. Reflux at 80°C for 60 minutes. Obtained Ni-ZIF-67 / CC composite material.

[0025] Step 2: Preparation of Ni-ZIF-67@CC / CNTS composite:

[0026] Put the Ni-ZIF-67 / CC composite material prepared in the first step into a porcelain boat, put the porcelain boat into a tube furnace, heat up to 600°C, first pass argon, then hydrogen, and finally acetylene, After the reaction was complet...

Embodiment example 2

[0030] The first step: Preparation of Ni-ZIF-67@CC composite material:

[0031] 1500mg of Co(NO 3 ) 2 ·6H 2 O was added to 200ml of anhydrous methanol and stirred; the 2-methylimidazole of 1700mg was added to 200ml of anhydrous methanol and stirred, and the solution mixed with 2-methylimidazole was slowly poured into the still stirring Co(NO 3 ) 2 ·6H 2 O solution and add a little carbon cloth, stir for 30min and let stand. After 24 h the solution was centrifuged and dried. Take 350mgNi(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of absolute alcohol, and the prepared ZIF-67 / CC was added to the above solution. Reflux at 80°C for 60 minutes. Obtained Ni-ZIF-67 / CC composite material.

[0032] Step 2: Carbonization of Ni-ZIF-67@CC / CNTS composite:

[0033] Put the Ni-ZIF-67 / CC composite material prepared in the first step into a porcelain boat, put the porcelain boat into a tube furnace, heat up to 700°C, first pass argon, then hydrogen, and finally acetylene, After the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com