Preparation of chitosan-covering zein nanoparticles and application thereof in load acacetin sodium salt

A technology of zein and chitosan, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, and drug combinations, etc., can solve the problems of poor chemical stability of acacetin sodium salt and the like , to achieve the effects of excellent stability, high drug encapsulation efficiency, and high nanoparticle yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Precisely weigh 100.1 mg of zein and dissolve it in 10 ml of 80% ethanol, ultrasonicate for 5 minutes to dissolve it completely, and place it in a 50 ml spray bottle;

[0036] (2) Measure 10ml of deionized water and place it in another 50ml spray bottle;

[0037] (3) At room temperature, spray two spray bottles in a closed device to obtain a milky white solution. The resulting solution was rotary evaporated at 50°C for 30 min to remove ethanol;

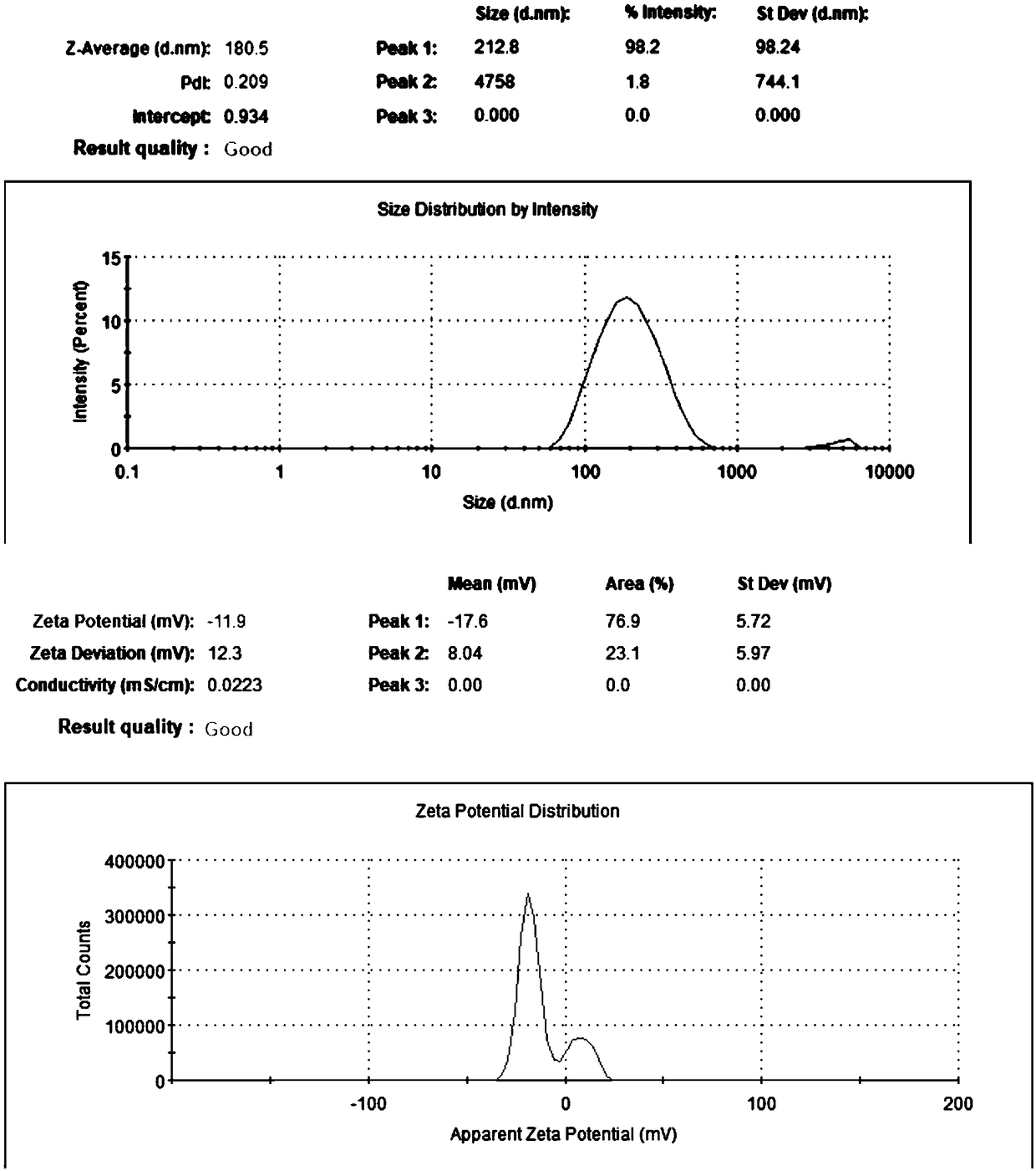

[0038] (4) Get the supernatant as a sample by centrifuging at 2000rpm for 10min, measure the particle size and potential of the product with nano-zs90 Malvern particle size and potential meter, the average particle size is about 180.5nm (polydispersity index=0.209), and the potential is -11.9mv, the particle size and potential distribution of nanoparticles are shown in the attached figure 1 .

Embodiment 2

[0040] (1) Precisely weigh 100.3 mg of zein, dissolve it in 10 ml of 80% ethanol, ultrasonicate for 5 minutes to dissolve it completely, and place it in a 50 ml spray bottle;

[0041] (2) Precisely weigh 5.2mg PEG400 and dissolve it in 10ml deionized water, sonicate for 5 minutes to dissolve it completely, and place it in another 50ml spray bottle;

[0042] (3) At room temperature, spray two spray bottles in a closed device to obtain a milky white solution. The resulting solution was rotary evaporated at 50°C for 30 min to remove ethanol;

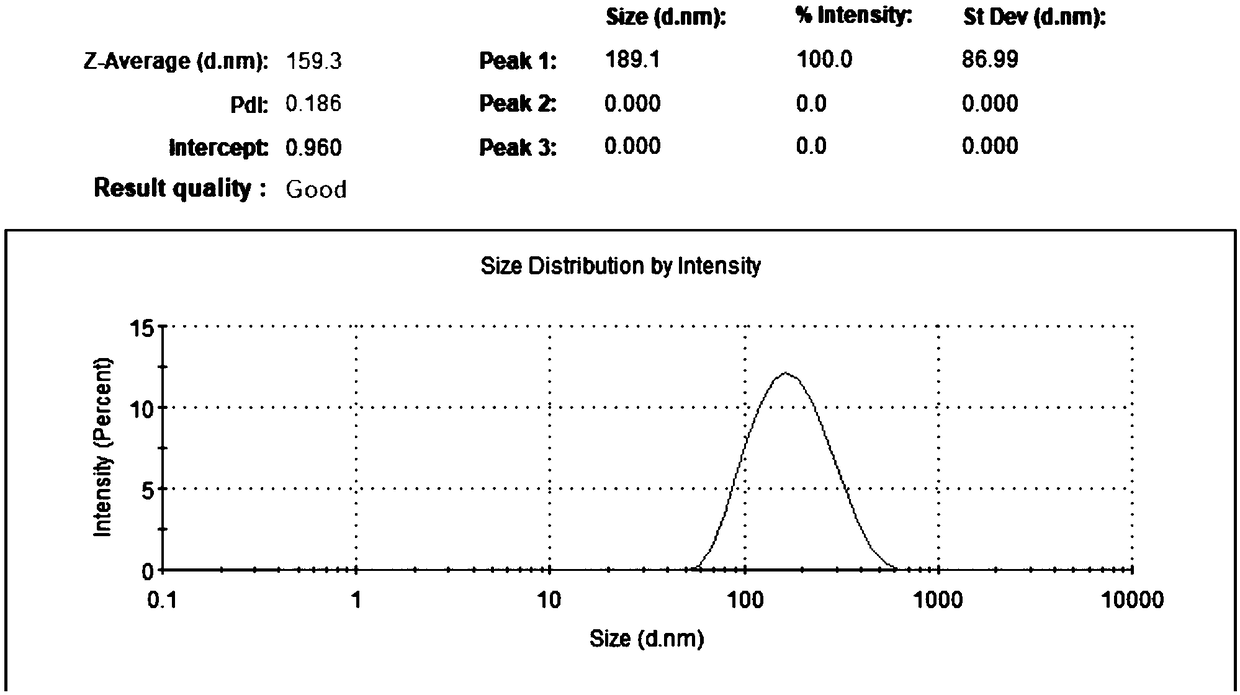

[0043] (4) The supernatant was taken as a sample by centrifugation at 2000 rpm for 10 min, and the particle size of the product was measured with a nano-zs90 Malvern particle size and potentiometer. The average particle size of the zein nanoparticles stabilized by 5% PEG400 is about 159.3nm (polydispersity index=0.186), and the particle size distribution diagram is shown in figure 2 .

Embodiment 3

[0045] (1) Precisely weigh 100.3 mg of zein, dissolve it in 10 ml of 80% ethanol, ultrasonicate for 5 minutes to dissolve it completely, and place it in a 50 ml spray bottle;

[0046] (2) Precisely weigh 5.3mg of F68 and dissolve it in 10ml of deionized water, sonicate for 5 minutes to dissolve it completely, and place it in another 50ml spray bottle;

[0047] (3) At room temperature, spray two spray bottles in a closed device to obtain a milky white solution. The resulting solution was rotary evaporated at 50°C for 30 min to remove ethanol;

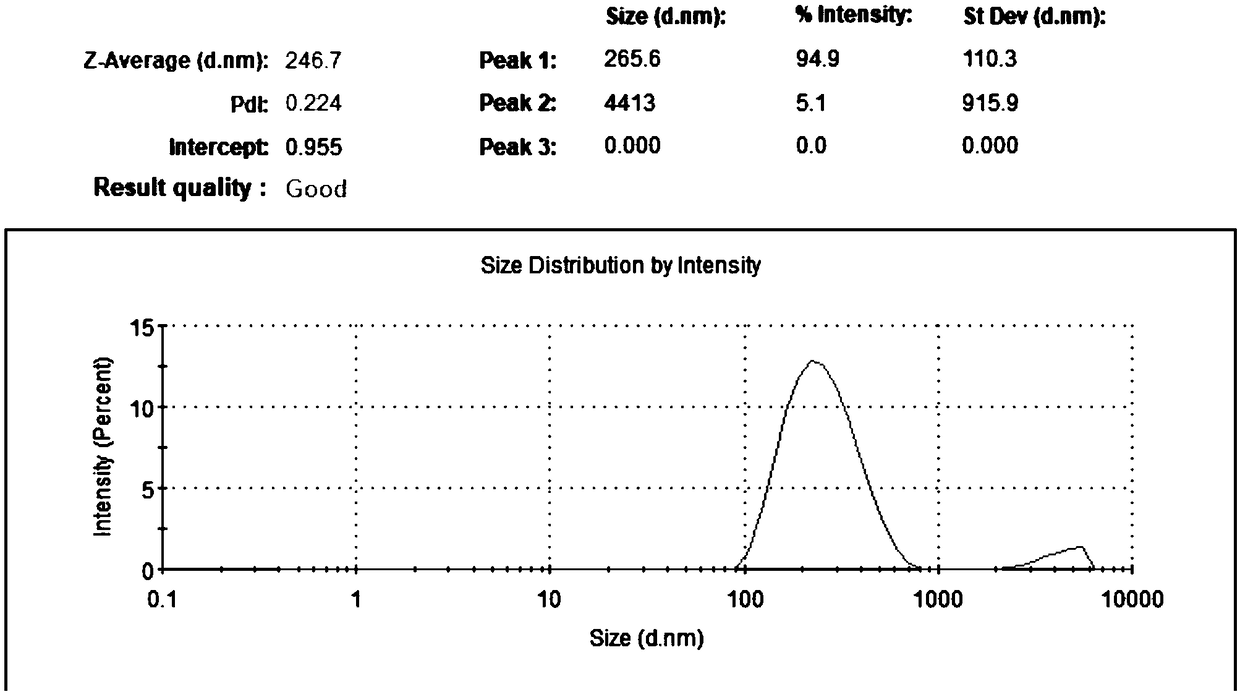

[0048] (4) Take the supernatant as a sample by centrifuging at 2000rpm for 10min, measure the particle diameter of the product with a nano-zs90 Malvern particle diameter and potentiometer, and the particle diameter of the zein nanoparticles stabilized by 5% F68 is about 246.7nm (polydispersity index=0.224), particle size distribution figure sees image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com