Artificial ecological stone and preparation method thereof

An ecological stone and man-made technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increasing the cost of waste concrete, the plastic board is not ecological and environmentally friendly, and the strength is difficult to guarantee, and achieves increased physical bonding capacity, price reduction, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

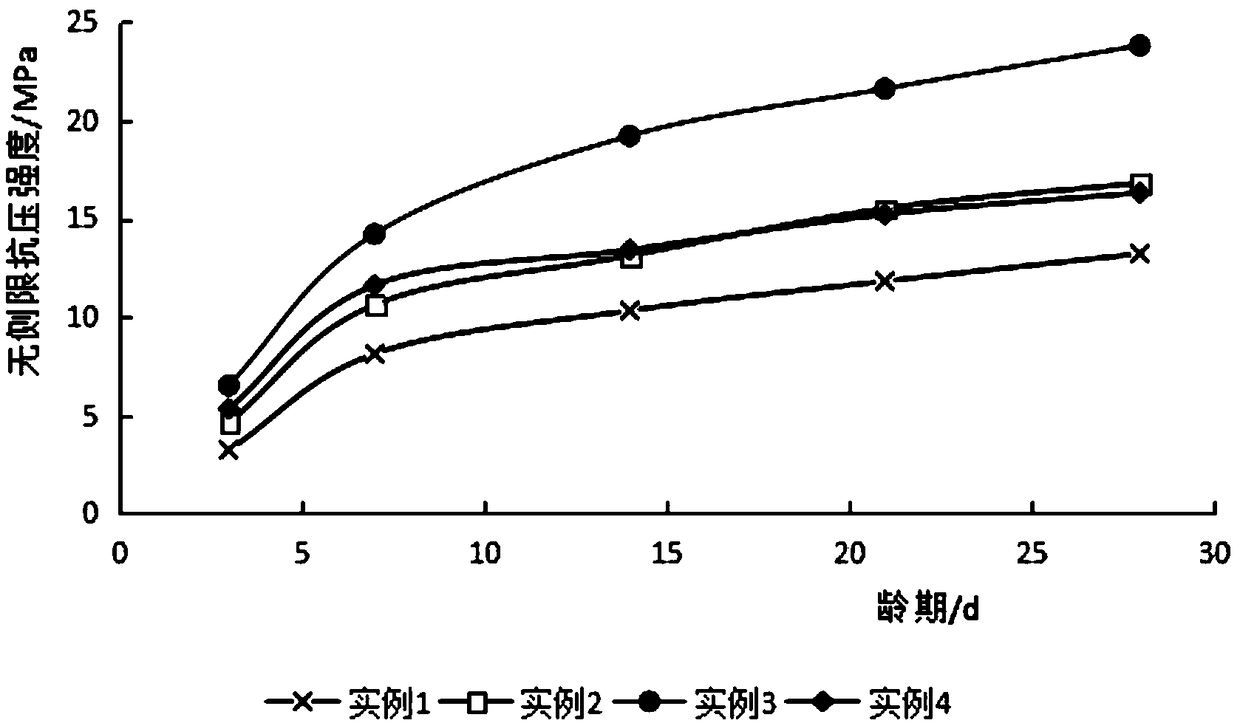

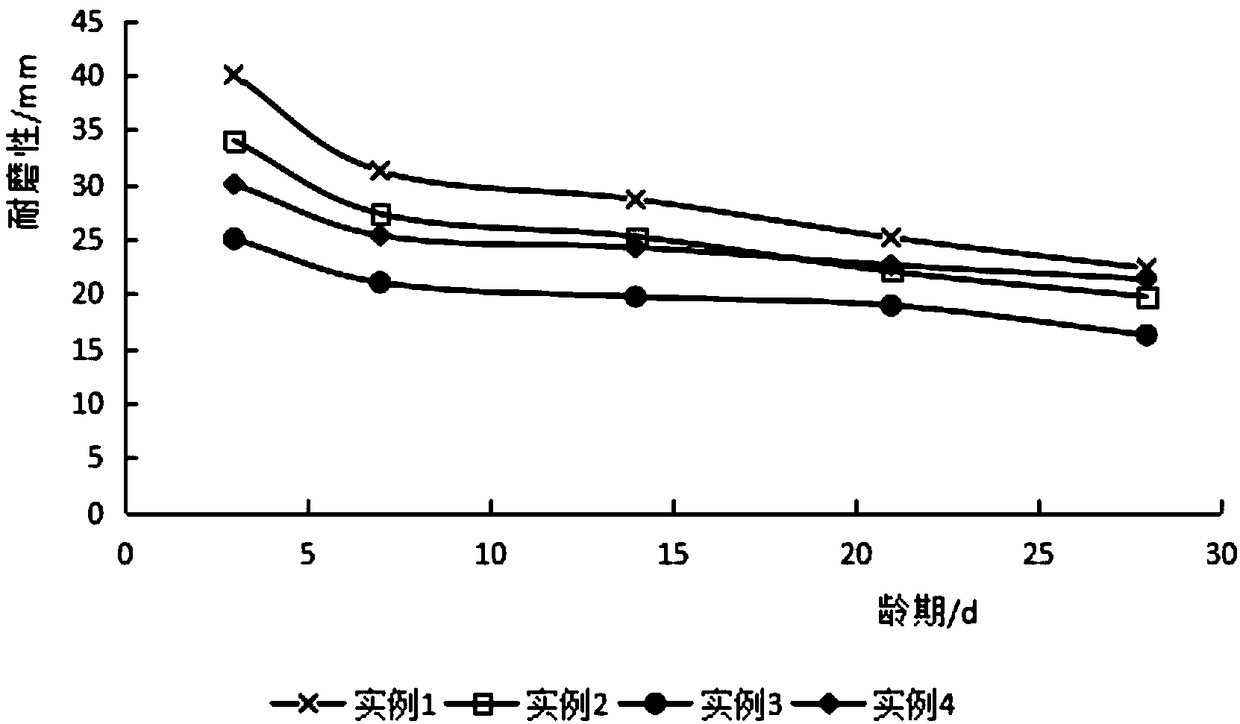

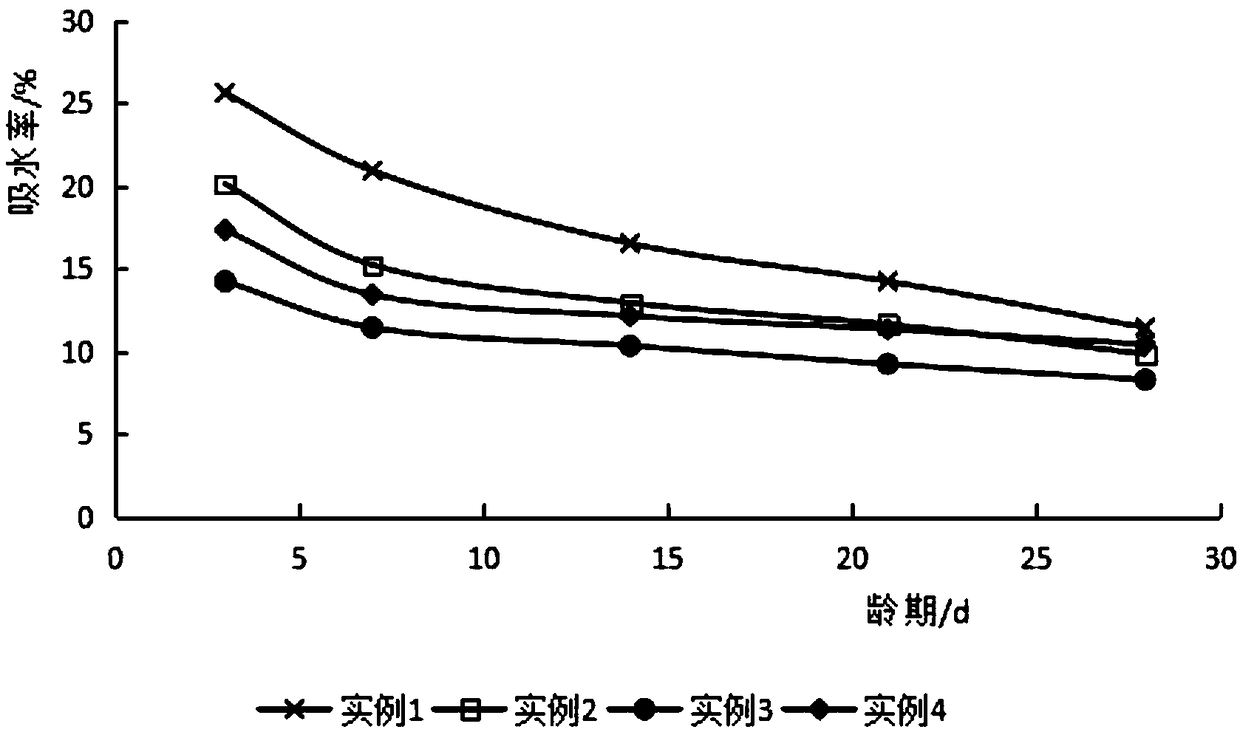

[0044] The ratio by weight is: 6 parts by weight of No. 425 ordinary Portland cement, 10 parts by weight of mineral powder, 8 parts by weight of water, 0.05 parts by weight of polyurethane, 0.02 parts by weight of sodium hydroxide, and 0.05 parts by weight of silane coupling agent. 0.1 parts by weight of hydroxyl liquid polybutadiene, 0.1 parts by weight of diethylaminoethanol, 0.3 parts by weight of silicon dioxide, and 0.02 parts by weight of fiber balls. After the above materials are mixed and stirred evenly, mix them with dredged soil according to the ratio of 20%: 80%, stir evenly and make molds for maintenance, and test the unconfined compressive strength under the ages of 3d, 7d, 14d, 21d, and 28d respectively , wear resistance, water absorption and frost resistance.

Embodiment 2

[0046] The ratio by weight is: 8 parts by weight of No. 425 ordinary Portland cement, 12 parts by weight of mineral powder, 10 parts by weight of water, 0.07 parts by weight of polyurethane, 0.04 parts by weight of triethanolamine, 0.07 parts by weight of silane coupling agent, terminal hydroxyl 0.12 parts by weight of liquid polybutadiene, 0.12 parts by weight of diethylaminoethanol, 0.4 parts by weight of silicon dioxide, and 0.03 parts by weight of fiber balls. After the above materials are mixed and stirred evenly, they are mixed with dredged soil according to the ratio of 20%:80%, stirred evenly, molded and maintained, and tested for unconfined compressive strength at ages 3d, 7d, 14d, 21d, and 28d respectively , wear resistance, water absorption and frost resistance.

Embodiment 3

[0048] The proportion by weight is: 10 parts by weight of No. 425 ordinary Portland cement, 14 parts by weight of mineral powder, 12 parts by weight of water, 0.09 parts by weight of polyurethane, 0.02 parts by weight of triethanolamine, 0.04 parts by weight of sodium hydroxide, silane coupling 0.09 parts by weight of agent, 0.14 parts by weight of hydroxyl-terminated liquid polybutadiene, 0.14 parts by weight of diethylaminoethanol, 0.5 parts by weight of silicon dioxide, and 0.04 parts by weight of fiber balls. After mixing and stirring the above materials evenly, mix them with the dredged soil according to the ratio of 20%:80%, stir evenly, make molds and maintain them, and test the unconfined compressive strength under the ages of 3d, 7d, 14d, 21d, and 28d respectively , wear resistance, water absorption and frost resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com