A kind of preparation method of epoxy resin based on silicon thiazole dopo type flame retardant modification

An epoxy resin and flame retardant technology, which is applied in the field of epoxy resin preparation based on silicon thiazole DOPO type flame retardant modification, can solve the problems of limited application scope, reduced thermal stability and mechanical properties, and decreased Tg value. , to achieve the effect of improving compatibility, good flame retardant effect and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

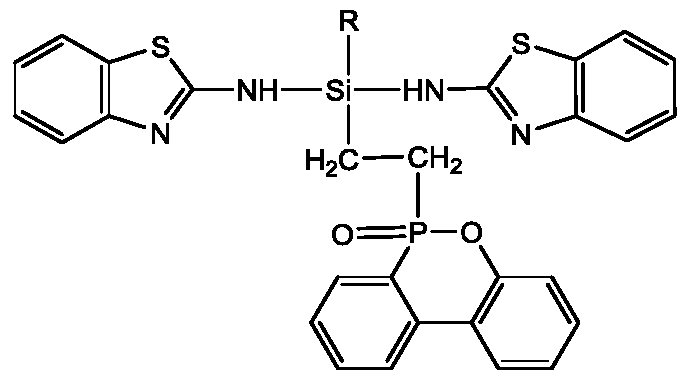

Image

Examples

Embodiment 1

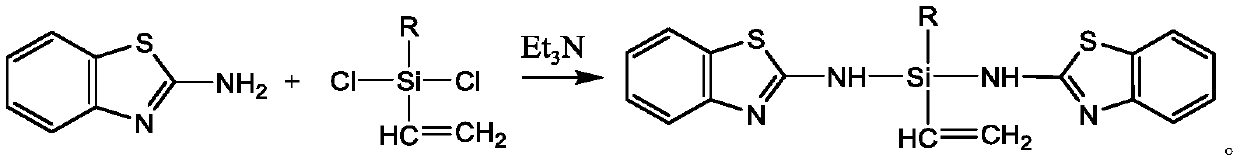

[0037] Under the protection of high-purity nitrogen, 2-aminobenzothiazole (40mmol) and triethylamine (6ml) were added to a three-necked flask, and dichloromethylvinylsilane (20mmol) and tetrahydrofuran were added dropwise through a constant pressure dropping funnel (40ml) of the mixed solution, the temperature of the whole system is controlled at 30 ° C, after the dropwise addition is completed, the reaction is continued at this temperature for 5 h, after the reaction is completed, it is left to settle, and the hydrochloride of triethylamine is removed by suction filtration, and the filtrate is collected and used Wash with anhydrous ether, remove the solvent by rotary evaporation, and dry in vacuum to obtain vinyldiaminobenzothiazole.

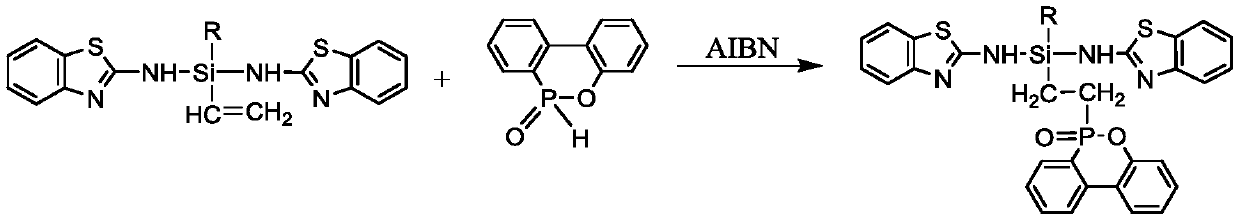

[0038] Under high-purity nitrogen protection, the mixture of DOPO (16.5mmol), vinyl diaminobenzothiazole (15mmol) and toluene (30ml) is added in the 150ml three-necked flask that magnetic stirrer and reflux condenser tube are housed, be warming ...

Embodiment 2

[0043] The silicon-containing thiazole DOPO type flame retardant synthesized in Example 1 (mass fraction is 2.5%) is used as a flame retardant modifier, and 4,4-diaminodiphenylmethane (mass fraction is 17.1%) is used as a curing agent to prepare a modified E44 epoxy resin material.

[0044] Weigh silicon-containing thiazole DOPO flame retardant (3.11g) and slowly add it into E44 epoxy resin (100g), stir at 100°C for 20min to obtain a homogeneous mixture. Then the obtained epoxy resin and 4,4-diaminodiphenylmethane (21.30 g) were stirred at 100° C. for 5 min until the curing agent was completely dissolved. Finally, the epoxy resin mixture was poured into the mold for heating and curing. The curing program was 100°C for 120 minutes and 150°C for 120 minutes to prepare a modified epoxy resin material with a flame retardant content of 2.5%.

Embodiment 3

[0046] The silicon-containing thiazole DOPO type flame retardant synthesized in Example 1 (mass fraction is 5%) is used as a flame retardant modifier, and 4,4-diaminodiphenylmethane (mass fraction is 16.3%) is used as a curing agent to prepare a modified E44 epoxy resin material.

[0047] Weigh silicon-containing thiazole DOPO flame retardant (6.36g) and slowly add to E44 epoxy resin (100g), stir at 100°C for 20min to obtain a homogeneous mixture. Then the obtained epoxy resin and 4,4-diaminodiphenylmethane (20.75 g) were stirred at 100° C. for 10 min until the curing agent was completely dissolved. Finally, the epoxy resin mixture was poured into the mold for heating and curing. The curing program was 100°C for 120 minutes and 150°C for 150 minutes to prepare a modified epoxy resin material with a flame retardant content of 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com