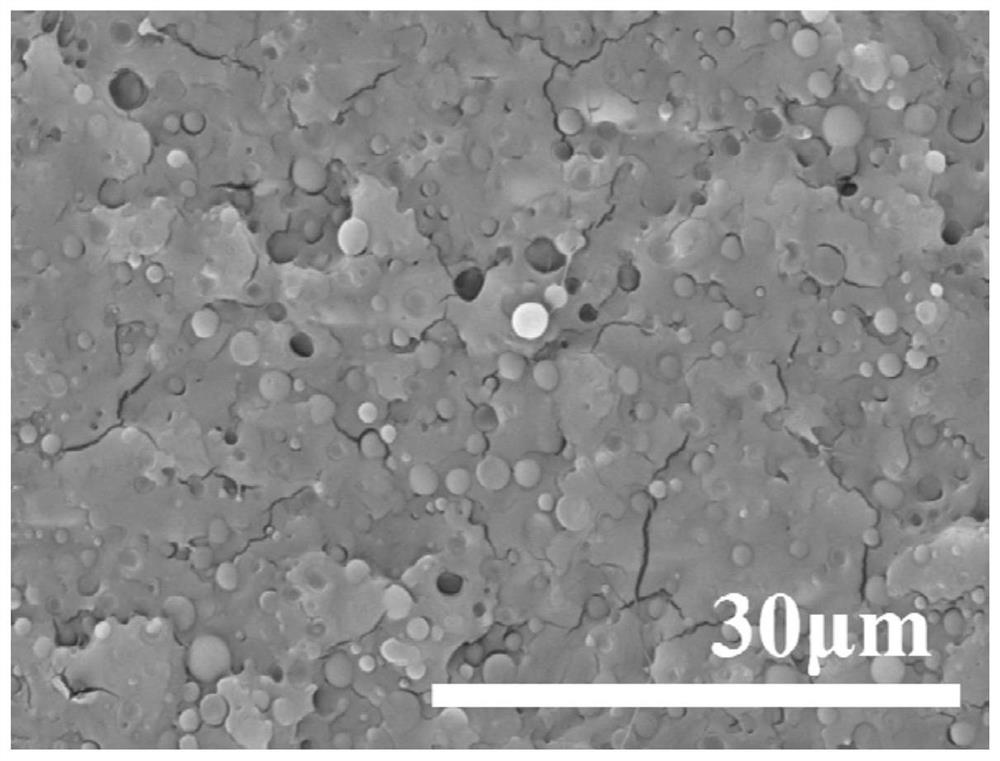

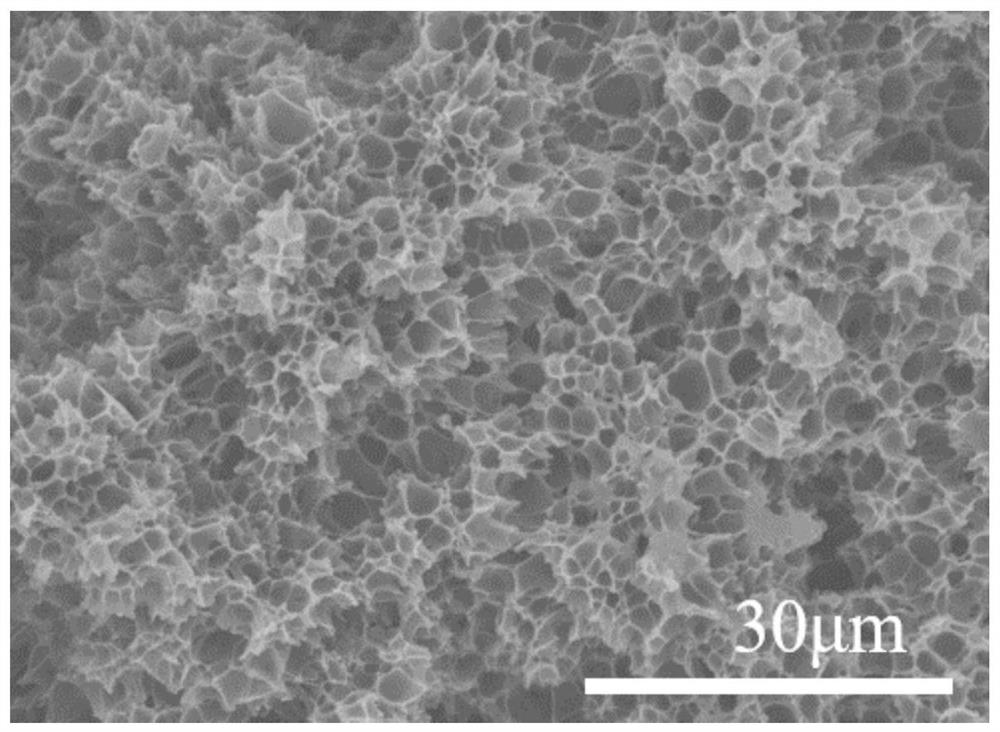

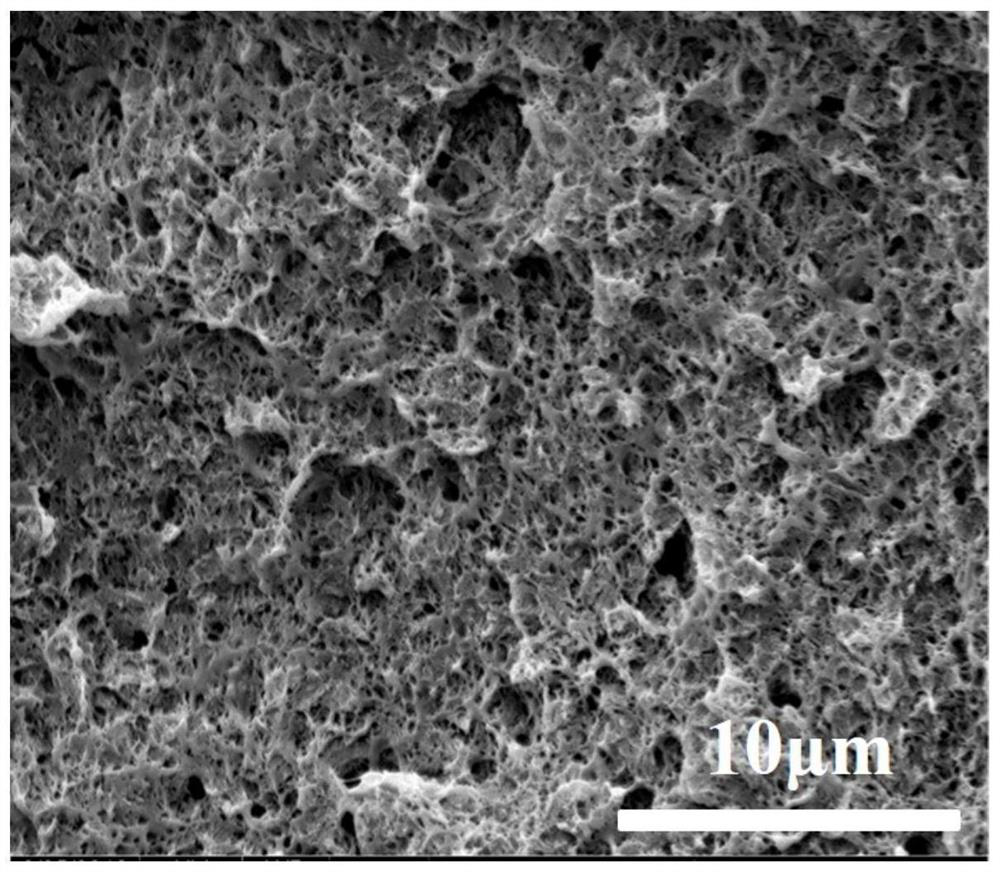

A kind of polylactic acid nano-cell foam material and preparation method thereof

A foaming material, polylactic acid technology, applied in the field of biodegradable polymer foaming material and its preparation, can solve the problems of uneven cell, low cell density, large cell size, etc., and achieve the purpose of suppressing the cell The effect of growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a polylactic acid nanocellular foaming material, and its raw materials are as follows:

[0036] Polylactic acid, 2003D, Natureworks, USA; L-lactic acid content greater than 98%, melt flow rate 6g / 10min, melt strength 100mN;

[0037]Chain extender master batch (containing 10% epoxy oligomer), Joncryl 4360, German BASF company;

[0038] Nucleating agent PPZn (phenyl zinc phosphate), self-made in the laboratory; nucleating agent diameter 0.1-10μm, melting point 250-350℃;

[0039] Carbon dioxide, purity>99%, commercially available;

[0040] The specific content is shown in Table 1.

[0041] Table 1

[0042] sample Polylactic acid (parts) PBAT (number of copies) Nucleating agent (number of parts) Chain extender (parts) 1 100 0 0 0 2 100 0 0 3 3 100 0 0.5 3 4 100 0 0.5 0 5 80 20 0.5 3

[0043] The polylactic acid nanocellular foam material provided in this example is prepared according ...

Embodiment 2

[0051] This embodiment provides a polylactic acid nanocellular foaming material, and its raw materials are as follows:

[0052] Polylactic acid, 2003D, Natureworks, USA; L-lactic acid content greater than 98%, melt flow rate 6g / 10min, melt strength 100mN;

[0053] Poly adipate / butylene terephthalate, C1200, German BASF company;

[0054] Carbon dioxide, purity>99%, commercially available;

[0055] The specific content is shown in Table 3.

[0056] table 3

[0057] sample Polylactic acid (parts) PBAT (number of copies) 1 90 10 2 80 20 3 70 30

[0058] Put the above components in a vacuum drying oven, dry at 60°C for more than 10 hours to remove moisture, and then mix polylactic acid, polyadipate / butylene terephthalate (PBAT) according to the component ratios in Table 3 The agent was melt-blended at 190°C for 15 minutes through an internal mixer, and the speed of the internal mixer was 60 rpm; then the blend material was hot-pressed at 190°...

Embodiment 3

[0065] This embodiment provides a polylactic acid nanocellular foaming material, and its raw materials are as follows:

[0066] Branched polylactic acid, synthesized in laboratory, molecular weight 220,831g / mol, melt flow rate 4.7g / 10min, melt strength 300mN;

[0067] Carbon dioxide, purity>99%, commercially available;

[0068] The branched polylactic acid was placed in a vacuum drying oven, dried at 60°C for more than 10 hours to remove moisture, and then hot-pressed at 190°C to form a 2mm-thick sheet for foaming, and the hot-pressing time was 10min.

[0069] In the second step, put the sample prepared in the previous step into the autoclave and inject supercritical CO 2 Carry out pressure foaming in the kettle, the soaking temperature in the kettle is 100°C, and the soaking pressure is 20MPa; after isothermal and pressure soaking for a certain period of time (as shown in Table 5), open the pressure relief valve to quickly release the pressure in the kettle to normal pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com