A kind of low-density polyvinyl chloride foam material and preparation method thereof

A technology of polyvinyl chloride and foaming materials, applied in the field of low-density polyvinyl chloride foaming materials and its preparation, can solve the problems of low density, poor flame retardancy, and high cost, and achieve low density and overcome poor flame retardancy , to overcome the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

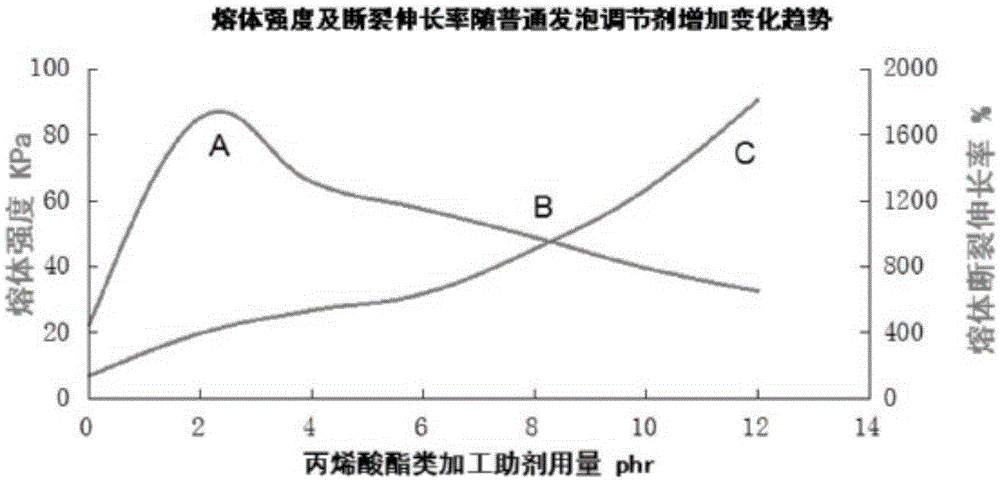

[0094] According to the same preparation method and extrusion process of Comparative Examples 1-7, the foamed material is prepared, and the melt strength and melt elongation at break are detected according to the detection standards of Comparative Examples 1-7. The experimental data are shown in Table 6 and figure 2 , the density of the foamed rod at the three points A, B, and C are 0.856, 0.522, and 0.297g / cm respectively 3 .

[0095] Table 6 comparative examples 8-14 melt strength and melt elongation at break data

[0096]

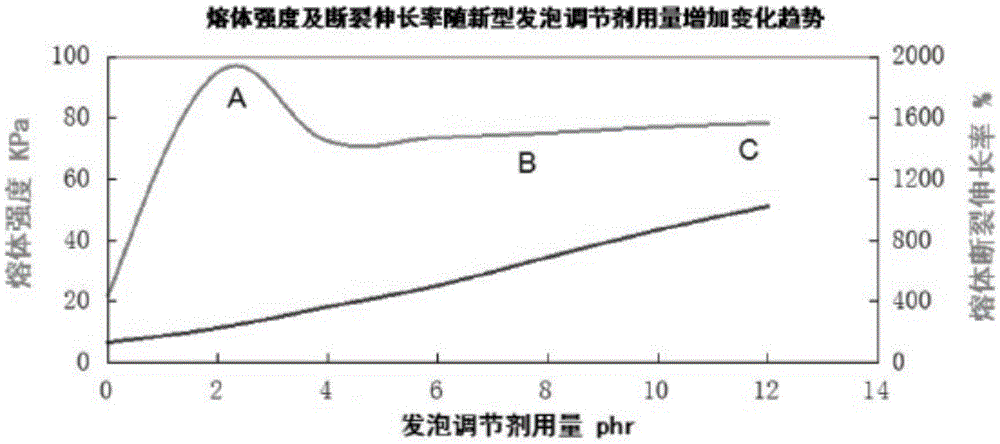

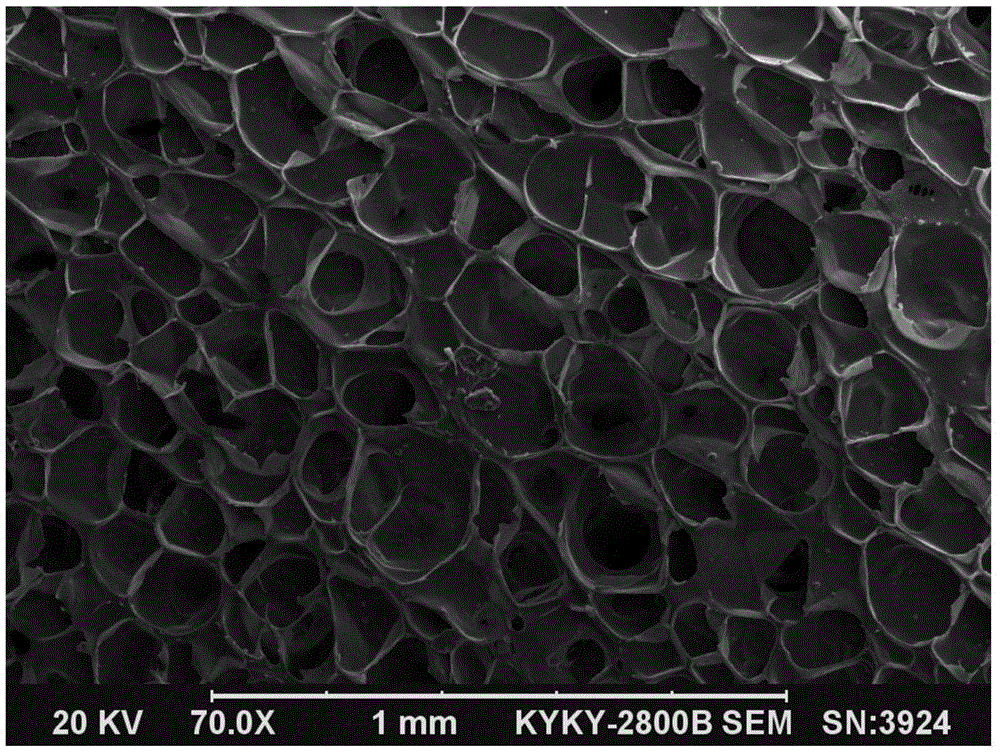

[0097] From Table 6 and figure 2 It can be seen that with the increase of the amount of foaming regulator in the PVC foaming formula, the melt strength gradually increases. long rate. we are at figure 2 Mark three points A, B, and C in the middle, and compare their influence on the density and cell structure of the foamed rod as follows: Figure 4 As shown, when the amount of foam regulator is small ( figure 2 As shown in point A), the melt ...

Embodiment 15

[0106] The preparation process of Example 15 is: adding the raw materials of the foaming material into a high-speed mixer, adding polyvinyl chloride resin and organotin stabilizer at 51°C; adding stearic acid, oxidized polyethylene wax, paraffin wax, Sodium bicarbonate and azodicarbonamide; add lubricating processing aids and foam regulators at 69°C; add calcium carbonate and titanium dioxide at 74°C, then complete the mixing at 108°C, pass through a 40-mesh sieve, and pass through the screw The extruder is melted and extruded, the barrel temperature of the screw extruder includes the temperature ranges of 154°C, 159°C, 164°C, 159°C and 159°C, the main engine speed of the screw extruder is 6.5rpm, and the melting The pulling speed during extrusion was 1.8 m / min.

Embodiment 16

[0107] The preparation process of Example 16 is as follows: add the raw materials of the foaming material into a high-speed mixer, add polyvinyl chloride resin and calcium zinc stabilizer at 52°C; add paraffin wax, oxidized polyethylene wax, calcium stearate at 61°C , potassium bicarbonate and azodicarbonamide; add lubricating processing aids and foam regulators at 70°C; add calcium carbonate and fluorescent whitening agent at 76°C, then complete the mixing at 106°C and pass through a 40-mesh sieve , melted and extruded through a screw extruder, the barrel temperature of the screw extruder includes the temperature ranges of 156°C, 161°C, 166°C, 161°C and 161°C, and the speed of the main engine of the screw extruder is 7.5rpm, The pulling speed during the melt extrusion is 2.2 m / min.

[0108] Detect melt strength and melt elongation at break according to the detection standards of Comparative Examples 1-7, the experimental data are shown in Table 7, and the density and cell str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com