Flexible curing agent for fluorocarbon coating and preparation method of flexible curing agent

A technology of fluorocarbon coating and curing agent, applied in the direction of coating, etc., can solve the problems of low elongation, poor low temperature resistance, insufficient flexibility, etc., and achieve the effect of good tensile strength and good yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

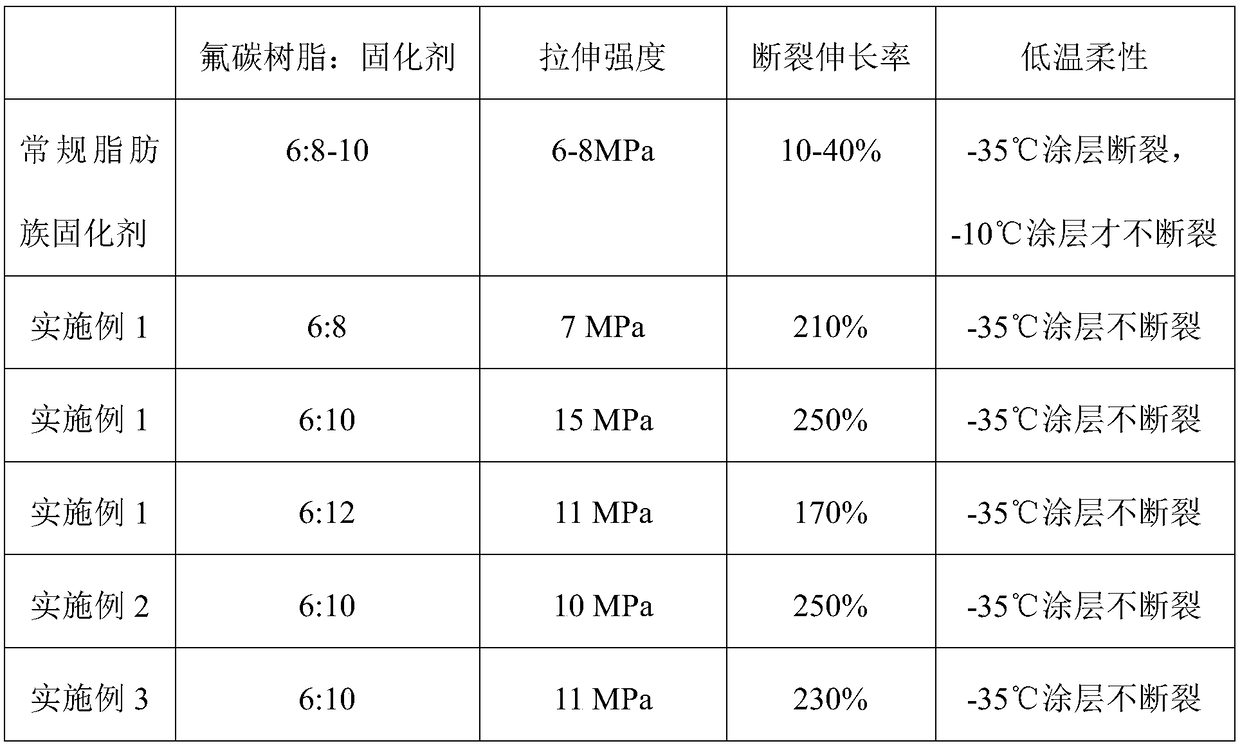

Examples

Embodiment 1

[0023] Preparation of modified polyether polyol with low unsaturation and high molecular weight: 100 parts by weight of difunctional polyol with molecular weight of 6000-10000, 60 parts by weight of trifunctional polyol with molecular weight of 6000-10000, 20 parts by weight of Polytetrahydrofuran ether with a temperature of 2000-4000 and 3 parts by weight of aliphatic isocyanate are reacted to synthesize a modified polyether polyol with low unsaturation and high molecular weight. The reaction temperature is 80-90°C and the reaction time is 0.5-2h.

[0024] Preparation of curing agent: Put 100 parts by weight of modified polyether polyol with low unsaturation and high molecular weight and 20 parts by weight of polycarbonate diol into the reaction kettle, stir evenly, heat up to 110-120°C for 1-1.5 hours, and then Add 40 parts by weight of isophorone diisocyanate during the stirring process, and after stirring for 10 minutes, slowly add the diluted catalyst into the reaction ket...

Embodiment 2

[0026] Preparation of curing agent: Put 100 parts by weight of the modified polyether polyol with low unsaturation and high molecular weight prepared in Example 1, and 15 parts by weight of polycaprolactone diol into the reaction kettle, stir evenly, and heat up to 110-120°C Dehydration for 1-1.5 hours, then add 30 parts by weight of hexamethylene diisocyanate during the stirring process, and after stirring for 10 minutes, slowly add the diluted catalyst into the reactor according to the amount, the temperature is controlled at 90-95 °C, and the constant temperature reaction is 4- 5h, finally add ethyl acetate, stir for 0.5h, stop the reaction when the NCO reaches the set value, vacuum degassing for 0.5h, and discharge to obtain the curing agent.

Embodiment 3

[0028] Preparation of curing agent: Put 100 parts by weight of the modified polyether polyol with low unsaturation and high molecular weight prepared in Example 1, and 20 parts by weight of polycaprolactone diol into the reaction kettle, stir evenly, and heat up to 110-120°C Dehydration for 1-1.5 hours, then add 44 parts by weight of isophorone diisocyanate during the stirring process, and after stirring for 10 minutes, slowly add the diluted catalyst into the reactor according to the amount, the temperature is controlled at 90-95 °C, and the constant temperature reaction is 4- 5h, finally add xylene, stir for 0.5h, stop the reaction when NCO reaches the set value, vacuum degassing for 0.5h, and discharge to obtain the curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com