Bare concrete surfactant

A technology of fair-faced concrete and surface treatment agent, which is applied to biocide-containing paints, anti-fouling/underwater paints, coatings, etc. It can solve problems such as discoloration of clear-water concrete, limit design styles, corrosion, etc., and reduce construction complexity Increase, broaden the design style, enrich the effect of the color system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

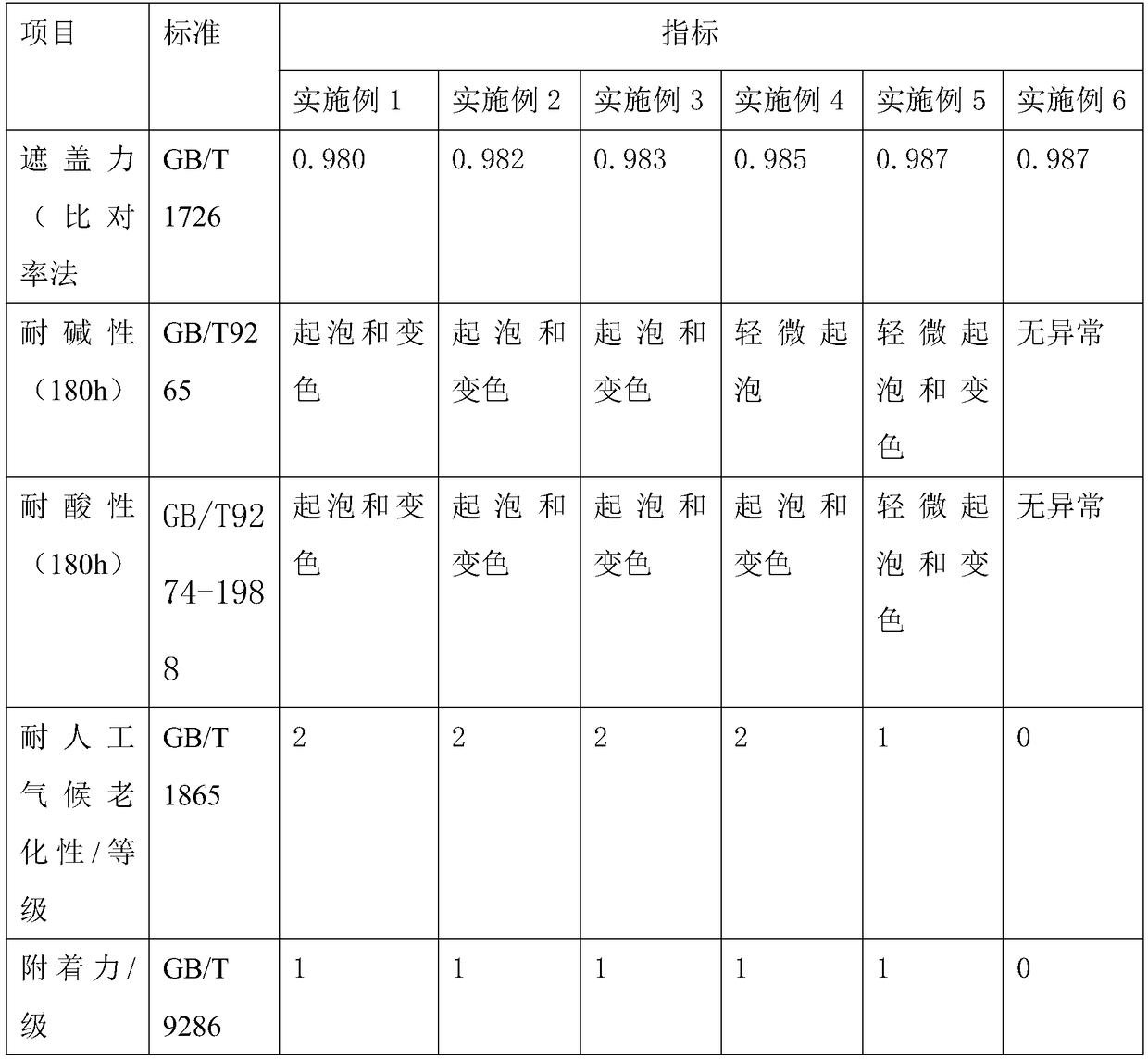

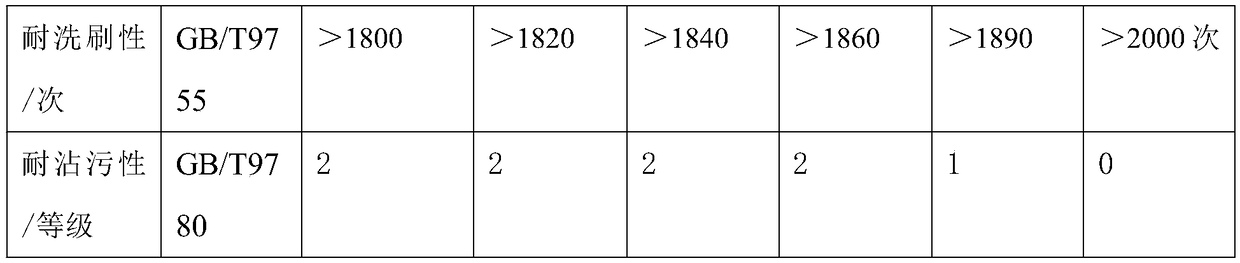

Examples

Embodiment 1

[0044] The surface treatment agent for clear-water concrete comprises the coloring material layer coated on the clear-water concrete surface, and the coloring material of the coloring material layer comprises the following components by weight percentage: dispersant 0.5%, quick penetrating agent 2%, matting agent 0.3%, defoamer 0.1%, aqueous emulsion 25%, pH regulator 3%, leveling agent 0.5%, wetting agent 0.2%, colorant 4.5%, redispersible latex powder 1.0%, deionized water 51.7%;

[0045] The preparation method of the coloring material is as follows:

[0046] (1) Add the deionized water, dispersant, wetting agent, defoamer, matting agent and aqueous emulsion in the mixer in the mass parts, and stir at 2500r / min for 15min to obtain the mixed solution 1;

[0047] (2) Continue to add the colorant, redispersible latex powder and leveling agent in parts by mass to the mixed solution 1 in the agitator, stir evenly and adjust the pH to ≤10 with a pH regulator to obtain the mixed so...

Embodiment 2

[0060] The surface treatment agent for fair-faced concrete comprises the coloring material layer coated on the clear-water concrete surface, and the coloring material of the coloring material layer comprises the following components by weight percentage: dispersant 0.7%, fast penetrating agent 3%, matting agent 0.5%, defoamer 0.3%, aqueous emulsion 35%, pH regulator 5%, leveling agent 0.8%, wetting agent 0.5%, colorant 7.0%, redispersible latex powder 2.5%, deionized water 58.6%;

[0061] The concrete component raw material of the colored material of the present embodiment is identical with embodiment 1;

[0062] The preparation method of the coloring material of the present embodiment is the same as embodiment 1;

[0063] The coating method of the surface treatment agent of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0065] The surface treatment agent for fair-faced concrete comprises the coloring material layer coated on the clear-water concrete surface, and the coloring material of the coloring material layer comprises the following components by weight percentage: dispersant 0.6%, fast penetrating agent 2.5%, matting agent 0.4%, defoamer 0.15%, aqueous emulsion 27%, pH regulator 4%, leveling agent 0.7%, wetting agent 0.4%, colorant 4.5%, redispersible latex powder 2%-, deionized water 55.5% ;

[0066] The concrete component raw material of the colored material of the present embodiment is identical with embodiment 1;

[0067] The preparation method of the coloring material of this embodiment is the same as that of Embodiment 1.

[0068] The coating method of the surface treatment agent of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com