Preparation method of multifunctional dyed fluorescent cotton fabric based on MOF

A technology for dyeing fluorescent and cotton fabrics, applied in dyeing, textile and papermaking, etc., can solve the problems of poor mechanical properties and mechanical stability, single luminescence mode, poor fluorescence effect, etc., to improve luminous efficiency and high fluorescence stability. , The effect of low difficulty in waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

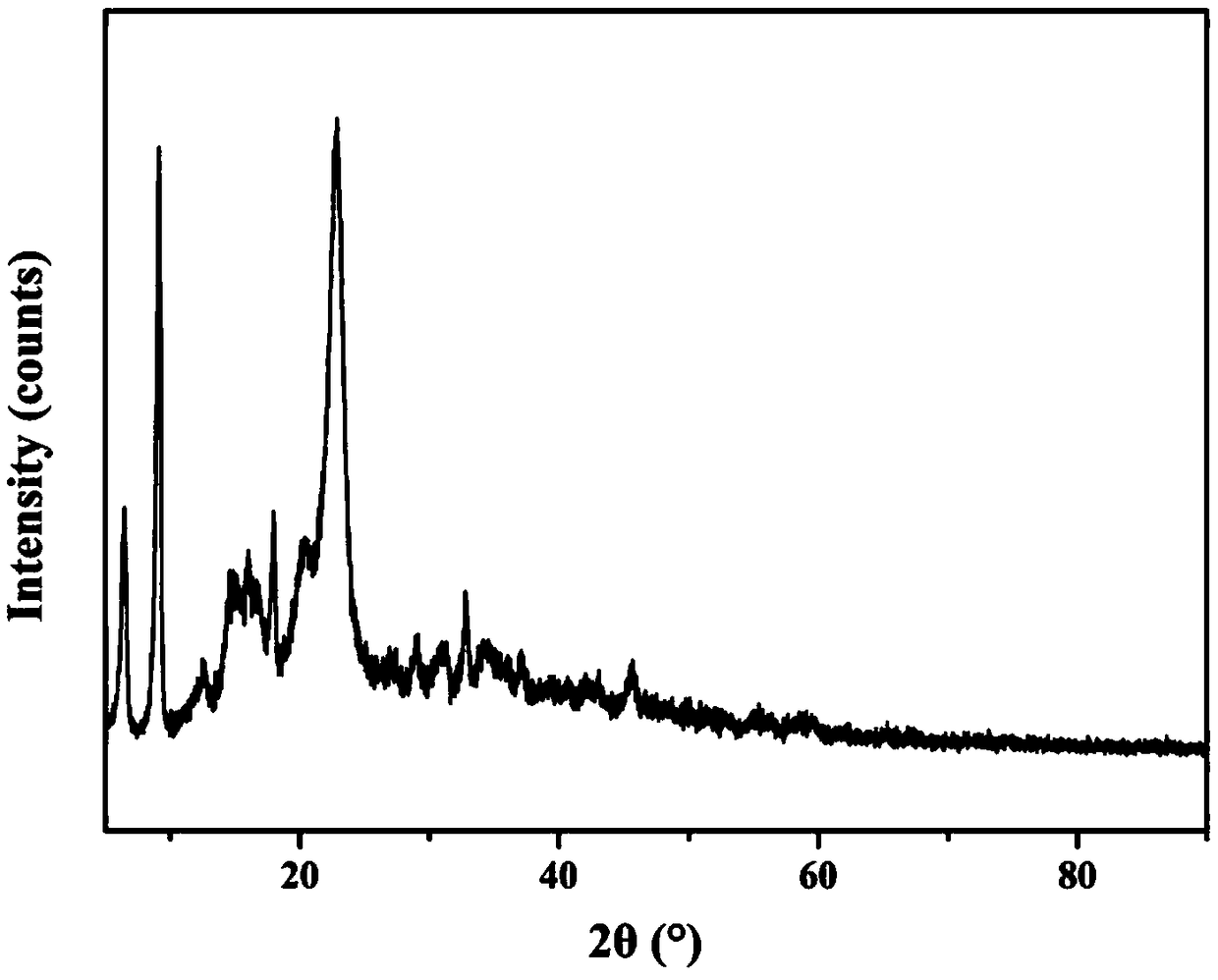

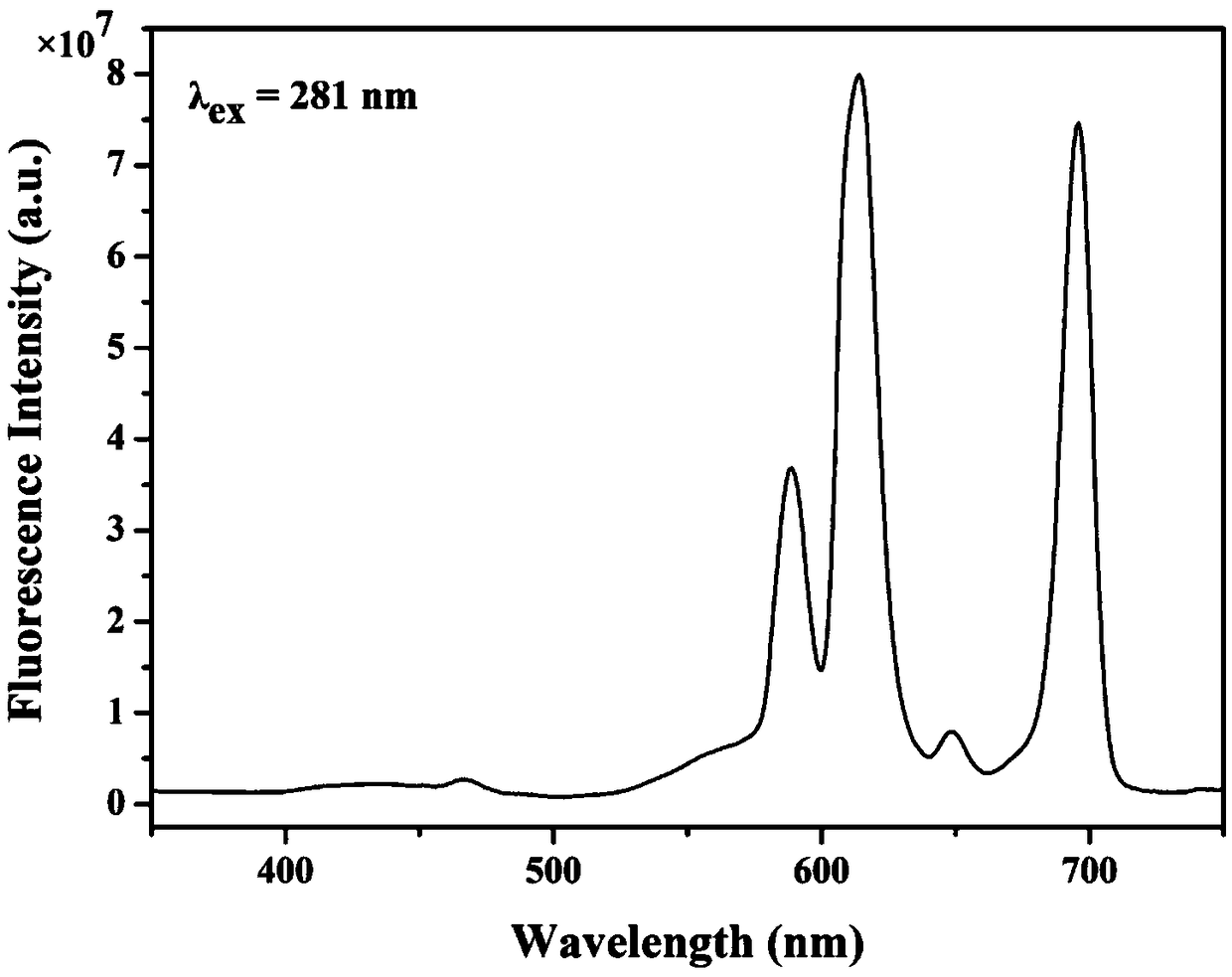

[0046] (1) Prepare 0.8mol / L zinc acetate aqueous solution A and 0.4mol / L terephthalic acid aqueous solution B respectively. Cotton fabrics were soaked in solution A at 70-75°C for 5 minutes with a liquor ratio of 1:50, washed with water at room temperature, and dried at 80°C for 30 minutes; then soaked in solution B under the same process conditions as solution A, washed with water, drying. After repeating the above steps 8 times, the Zn-MOF pretreated cotton fabric was obtained.

[0047] (2) Prepare chloroform solution C with rhodamine 6G dosage of 4.0% owf, bath ratio is 1:50, dip Zn-MOF pre-treated cotton fabric in solution C for 48 hours at 20°C, take it out, and place it in trichloromethane Rinse in methane and dry to obtain Zn-MOF dyed cotton fabric. Prepare a 0.1 mol / L europium acetate aqueous solution D, soak the Zn-MOF dyed cotton fabric in the solution D for 12 hours at 20°C, take it out, wash it with water at a bath ratio of 1:50, and dry it at 80°C for 45 minutes...

Embodiment 2

[0052] (1) Prepare 0.6mol / L zinc chloride aqueous solution A and 0.4mol / L trimesic acid aqueous solution B respectively. Cotton fabrics were soaked in solution A at 70-75°C for 5 minutes with a liquor ratio of 1:50, washed with water at room temperature, and dried at 90°C for 25 minutes; then soaked in solution B under the same process conditions as solution A, washed with water, drying. After repeating the above steps 8 times, the Zn-MOF pretreated cotton fabric was obtained.

[0053] (2) Prepare chloroform solution C with 2.0% owf of crystal violet, the bath ratio is 1:50, dip and dye the Zn-MOF pre-finished cotton fabric in solution C for 36 hours at 25°C, take it out in chloroform Rinse in medium and dry to get Zn-MOF dyed cotton fabric. Prepare a 0.05 mol / L europium chloride aqueous solution D, soak the Zn-MOF dyed cotton fabric in the solution D for 12 hours at 25°C, take it out, wash it with water at a bath ratio of 1:50, and dry it at 90°C for 30 minutes to obtain M...

Embodiment 3

[0055] (1) Prepare 0.4 mol / L zinc nitrate aqueous solution A and 0.1 mol / L pyromellitic acid aqueous solution B respectively. Cotton fabrics were soaked in solution A at 70-75°C for 8 minutes, with a bath ratio of 1:20, washed with water at room temperature, and dried at 100°C for 20 minutes; then soaked in solution B under the same process conditions as solution A, washed with water, drying. After repeating the above steps 12 times, the Zn-MOF pre-treated cotton fabric was obtained.

[0056] (2) Prepare a 0.01mol / L samarium chloride aqueous solution C, soak the Zn-MOF pretreated cotton fabric in the solution C for 18 hours at 30°C, take it out, wash it with water at a bath ratio of 1:20, and dry it at 100°C 20min, the fluorescent cotton fabric based on Zn-MOF was obtained. Prepare chloroform solution D with rhodamine B content of 1.0% owf, bath ratio is 1:20, dip and dye Zn-MOF-based fluorescent cotton fabric in solution D for 24 hours at 30°C, take it out in chloroform Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluorescence lifetime | aaaaa | aaaaa |

| Fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com