Preparation device and method for fly-ash-based mineral polymer thermal insulation materials

A technology of mineral polymers and thermal insulation materials, applied in the field of building materials, can solve the problems of cumbersome preparation and maintenance process, poor thermal insulation effect, poor fire resistance, etc., and achieve the effects of good mechanical properties, good processing performance, and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

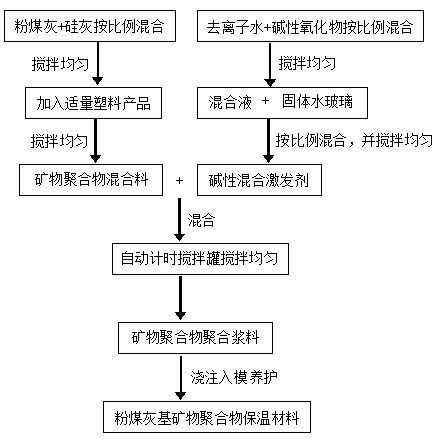

[0033] Embodiment 1: a kind of preparation method of fly ash-based mineral polymer thermal insulation material, comprises the following steps:

[0034] S1. Weigh an appropriate amount of alkaline oxide, and measure an appropriate amount of deionized water, mix the alkaline oxide and deionized water at a mass ratio of 40%, and stir evenly to obtain the alkaline oxide and deionized water. A mixture of ionized water;

[0035] S2. Weighing an appropriate amount of solid water glass, adding the solid water glass to the mixed solution prepared in S1 according to the ratio of 4-24% of the mass ratio of the alkali oxide to the solid water glass, and stirring evenly to prepare Alkaline mixed activator;

[0036] S3. Weigh a certain amount of fly ash and silica fume, use a pulverizer to grind the fly ash and silica fume, sieve it for later use, add silica fume and fly ash according to the mass ratio of 5-15% Into the mixer, stirring continuously for 5-15min to obtain a uniform solid po...

Embodiment 2

[0046] Embodiment 2: Based on Example 1, the difference is that potassium oxide and polyethylene foam are used as main raw materials, and 28g of basic potassium oxide is weighed, and 42g of deionized water is added to the weighed potassium oxide Mix in, stir evenly, obtain the mixed solution of alkaline oxide and deionized water, take by weighing 630g modulus and be the solid water glass of 1.5, join solid water glass in the mixed solution of potassium oxide and water, stir evenly, Prepare an alkaline mixed activator, weigh an appropriate amount of fly ash and silica fume, use a pulverizer to grind the fly ash and silica fume, sieve it for later use, and take 1662.5g of the pulverized 200-mesh sieve Add fly ash and 87.5g silica fume to the mixer, stir continuously for 5 minutes to obtain a uniform solid powder mixture, weigh 35g polyethylene foam, and add polyethylene foam to the solid powder mixture of fly ash and silica fume , and stirred for 10 minutes to prepare a uniform ...

Embodiment 3

[0047] Embodiment 3: Based on Examples 1 and 2, the difference is that sodium oxide and waste foam plastics are used as the main raw materials, and 182g of alkaline sodium oxide is weighed, and 273g of deionized water is added to the weighed oxidation Mix in sodium, stir evenly, obtain the mixed solution of alkaline oxide and deionized water, take by weighing 682.5g of solid water glass with a modulus of 2, add solid water glass to the mixed solution of sodium oxide and water, stir Evenly, prepare an alkaline mixed activator, weigh an appropriate amount of fly ash and silica fume, use a pulverizer to grind the fly ash and silica fume, and sieve it for later use. 1575g of fly ash and 175g of silica fume were added to the mixer, continuously stirred for 10min to obtain a uniform solid powder mixture, and 87.5g of waste foam was weighed, and waste foam was added to the solid powder mixture of fly ash and silica fume, and stirred for 15 minutes to prepare a uniform mineral polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com