Sialic acid and extraction method thereof

An extraction method, a technology of sialic acid, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of complex process, high cost, and many operation steps, and achieve the effect of simple operation and short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

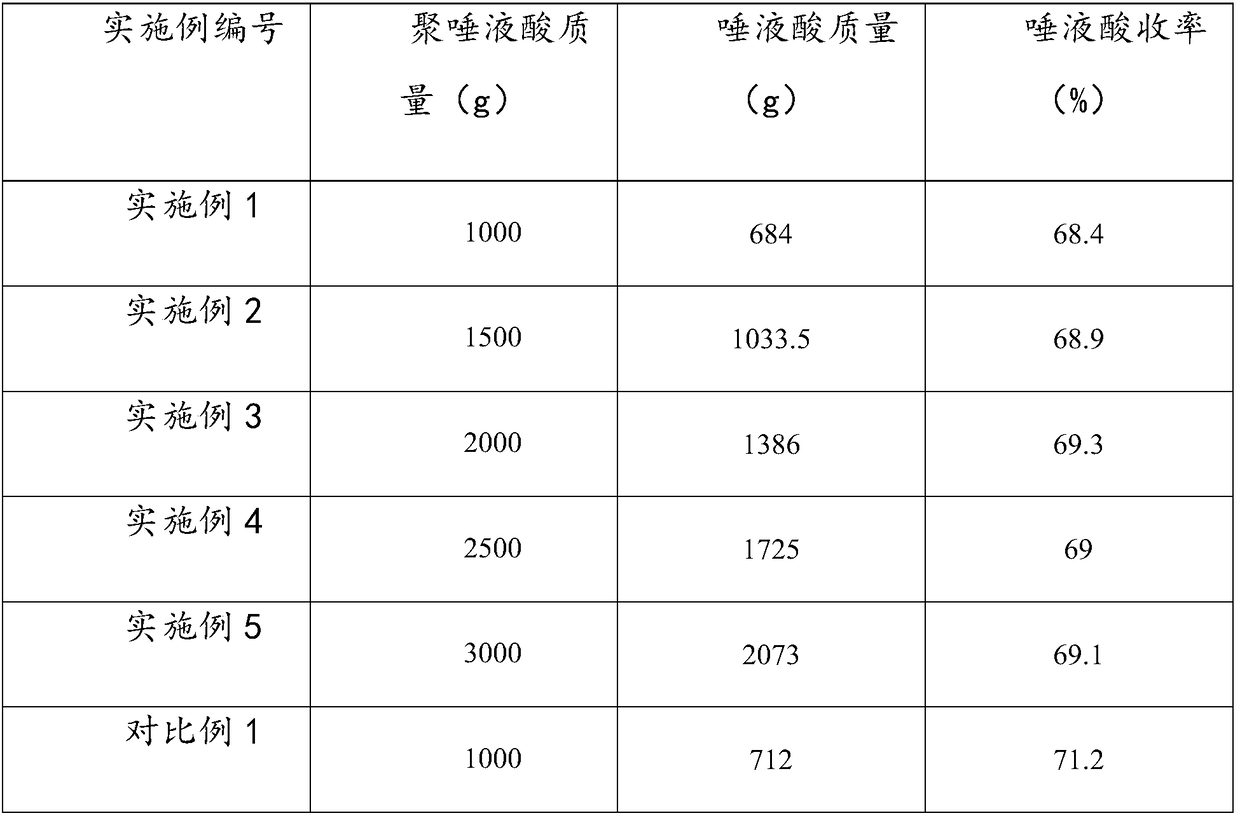

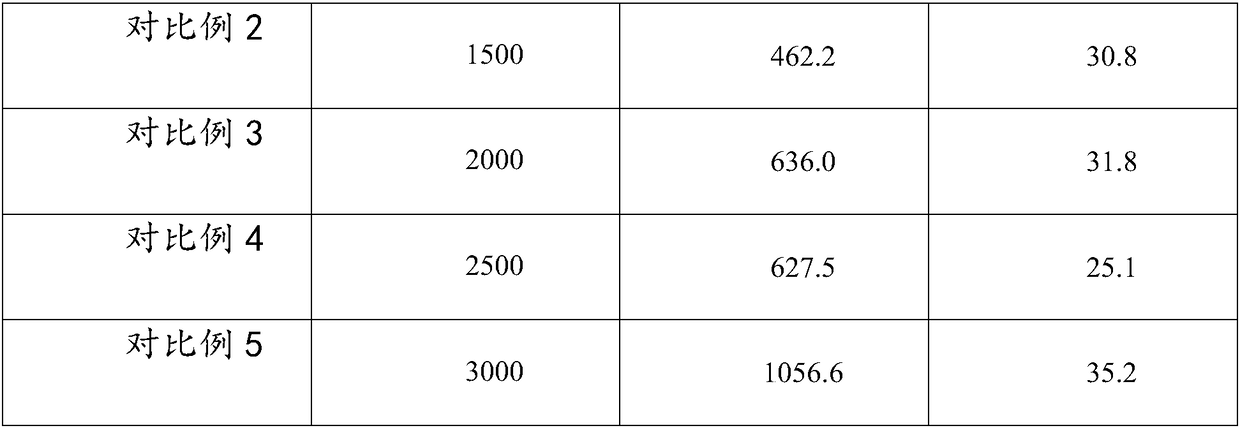

Examples

Embodiment 1

[0034]Use a 50nm ceramic membrane to filter the 10g / L polysialic acid fermentation broth, and then use an 8KDa ultrafiltration membrane to filter until the solid content of the solution is less than 3 times the polysialic acid content to obtain a polysialic acid solution. Add hydrochloric acid to the polysialic acid solution until the pH of the solution is 1, and react at a temperature of 80° C. for 4 hours to obtain a sialic acid solution. Adding to the sialic acid solution the ratio of 0.5% activated carbon to the sialic acid solution mass for decolorization treatment to obtain a decolorization solution, adding sodium hydroxide to the pH of the solution is 5 and obtains a sialate solution, and adopts a 0.5KDa ultrafiltration membrane to decolorize the solution The incompletely hydrolyzed polysialic acid was removed by filtration. A 200Da nanofiltration membrane is used to desalt the sialate solution, so that the solid content in the nanofiltration solution is less than three...

Embodiment 2

[0036] A 100nm ceramic membrane was used to filter the 15g / L polysialic acid fermentation broth, and then a 9KDa ultrafiltration membrane was used to filter until the solid content of the solution was less than 3 times the polysialic acid content to obtain a polysialic acid solution. Add hydrochloric acid to the polysialic acid solution until the pH of the solution is 1, and react at a temperature of 85° C. for 3 hours to obtain a sialic acid solution. Adding to the sialic acid solution the ratio of the mass of the sialic acid solution to the sialic acid solution is 1.5% activated carbon decolorization treatment to obtain a decolorization solution, adding sodium hydroxide to the pH of the solution is 5 and obtains a sialate solution, and adopts a 0.8KDa ultrafiltration membrane to decolorize the solution The incompletely hydrolyzed polysialic acid was removed by filtration. A 250Da nanofiltration membrane is used to desalt the sialate solution to obtain a nanofiltration soluti...

Embodiment 3

[0038] A 150nm ceramic membrane is used to filter the 20g / L polysialic acid fermentation broth, and then a 10KDa ultrafiltration membrane is used to filter until the solid content of the solution is less than 3 times the polysialic acid content to obtain a polysialic acid solution. Sulfuric acid was added to the polysialic acid solution until the pH of the solution was 2, and the reaction was carried out at a temperature of 90° C. for 2 hours to obtain a sialic acid solution. Adding to the sialic acid solution the ratio of the mass of the sialic acid solution to 2.5% gac decolorization treatment to obtain a decolorization solution, adding sodium hydroxide to the pH of the solution is 6 and obtains a sialate solution, and adopts an ultrafiltration membrane of 1.0KDa to decolorize the solution The incompletely hydrolyzed polysialic acid was removed by filtration. A 300Da nanofiltration membrane is used to filter the sialate solution to obtain a nanofiltration solution, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com