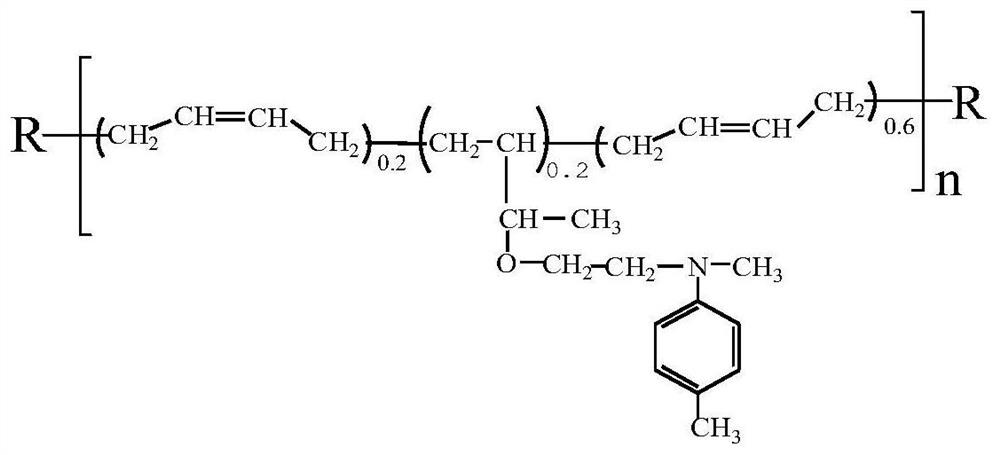

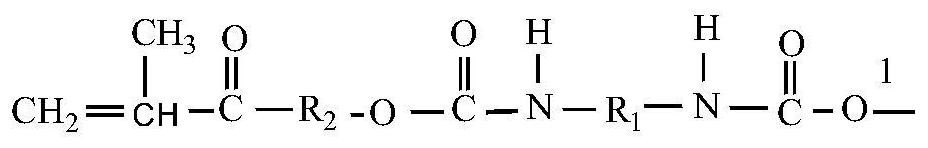

Synthesis of a Polymer Acrylate Resin with Photosensitive Autocatalytic Activity

An acrylate and self-catalyzed technology, applied in non-polymer adhesive additives, non-polymer organic compound adhesives, adhesive additives, etc., can solve poor surface dryness, poor toughness of cured products, and flexible adhesive layer sex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

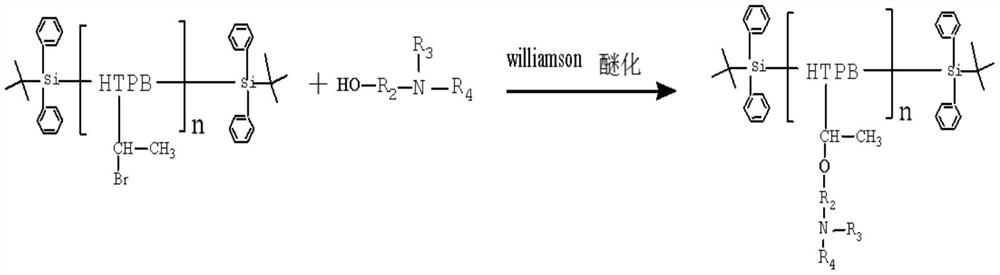

[0028] Take 430g of hydroxyl-terminated polybutadiene liquid rubber, add 30g of tert-butyldiphenylchlorosilane and 0.5g of diethyltetramethylimidazole under nitrogen protection, and react at 30°C for 4 hours to obtain silicon ether-protected rubber at both ends. the pretreatment;

[0029] Add the above-mentioned reactant to 22 g of HBr with a concentration of 40%, and react at 70° C. for 3 hours to obtain a halogenated hydrocarbon protected by silicon ether at both ends;

[0030] Add 55 g of N-methyl-N-hydroxyethyl-p-toluidine (CAS No. 2842-44-6) to the halogenated hydrocarbon protected with silicon ether at both ends prepared above, and react at 30°C under nitrogen protection for 3 hours;

[0031] Dissolve the product of the third step in tetrahydrofuran (THF) solvent, add catalyst tetraalkylammonium fluoride (TBAF) 0.26g, react at 25°C for 3-4h, and finally remove the solvent THF by rotary evaporation; after the above rotary evaporation The obtained product was vacuumized a...

Embodiment 2

[0033] Take 430g of hydroxyl-terminated polybutadiene liquid rubber, add 35g of tert-butyldiphenylchlorosilane and 1.5g of diethyltetramethylimidazole under nitrogen protection, and react at 40°C for 2 hours to obtain silicon ether-protected rubber at both ends. the pretreatment;

[0034] Add the above reactant to 20 g of HBr with a concentration of 40%, and react at 70°C for 3 hours to obtain a halogenated hydrocarbon protected by silicon ether at both ends;

[0035] Add 70 g of N-methyl-N-hydroxyethyl-p-toluidine (CAS No. 2842-44-6) to the halogenated hydrocarbon protected with silicon ether at both ends prepared above, and react at 30°C under nitrogen protection for 3 hours;

[0036] Dissolve the product of the third step in tetrahydrofuran (THF) solvent, add catalyst tetraalkylammonium fluoride (TBAF) 0.50g, react at 25°C for 3-4h, and finally remove the solvent THF by rotary evaporation; The obtained product was vacuumized at 110°C for 3 hours to remove moisture and othe...

Embodiment 3

[0038] Take 430g of hydroxyl-terminated polybutadiene liquid rubber, add 30g of tert-butyldiphenylchlorosilane and 1.0g of diethyltetramethylimidazole under nitrogen protection, and react at 40°C for 4 hours to obtain silicon ether-protected rubber at both ends. the pretreatment;

[0039] Add the above-mentioned reactant to 26 g of 40% HBr, and react at 70°C for 3 hours to obtain a halogenated hydrocarbon protected by silicon ether at both ends;

[0040] Add 48 g of N-methyl-N-hydroxyethyl-p-toluidine (CAS No. 2842-44-6) to the halogenated hydrocarbon protected with silicon ether at both ends prepared above, and react at 30°C under nitrogen protection for 3 hours;

[0041]Dissolve the product of the third step in tetrahydrofuran (THF) solvent, add catalyst tetraalkylammonium fluoride (TBAF) 0.38g, react at 25°C for 3-4h, and finally remove the solvent THF by rotary evaporation; after the above rotary evaporation The obtained product was vacuumized at 113°C for 2.5 hours to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com