A kind of preparation method of titanium dioxide film based on nanofluid

A nano-titanium dioxide and nano-fluid technology, applied in the field of thin film material preparation, can solve the problems of secondary pollution, limited application conditions, harsh reaction conditions, etc., and achieve the effect of stable structure, high repeatability, and rapid film formation at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

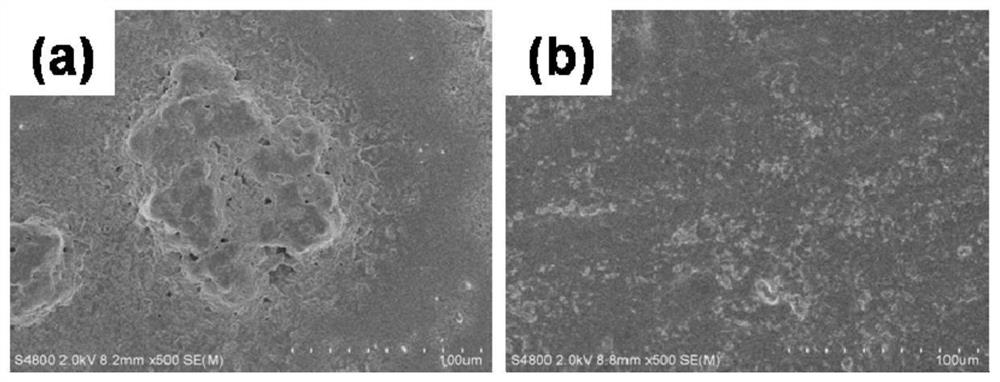

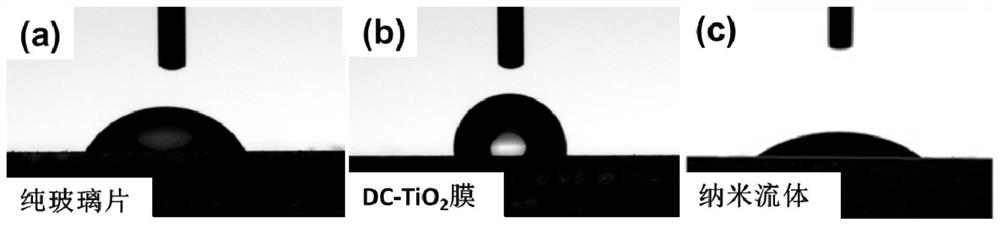

Image

Examples

Embodiment 1

[0039] (1) Add urea with a molar ratio of 1:1 to 0.5M Ti(SO 4 ) 2 In the aqueous solution, stir until the urea is completely dissolved, then add the solution into an autoclave with a filling degree of 80%, and keep the temperature at 180°C under hydrothermal conditions for 6 hours. The obtained product was repeatedly washed with deionized water until the filtrate was neutral, and finally dried at 80°C for 8 hours to obtain the product;

[0040] (2) Add 3 g of the above product into 25 mL of deionized water, ultrasonically disperse for 30 min, add 8 drops of aqueous sodium hydroxide solution (mass fraction 10%), and stir evenly for 7 days;

[0041] (3) Add 7 mL of DC5700 (CH 3 O) 3 Si(CH 2 ) 3 N + (CH 3 ) 2 (C 18 h 37 ) Cl - 40% methanol solution and 3mL KH550 (NH 2 (CH 2 ) 3 Si(OC 2 h 5 ) 3 ), after the white precipitate appeared, stop stirring, let it stand for 12 hours, wash with deionized water and centrifuge, repeat the cleaning and centrifugation process ...

Embodiment 2

[0045] (1) Add urea with a molar ratio of 1:1 to 0.5M Ti(SO 4 ) 2 In the aqueous solution, stir until the urea is completely dissolved, then add the solution into an autoclave with a filling degree of 80%, and keep the temperature at 180°C under hydrothermal conditions for 6 hours. The obtained product was repeatedly washed with deionized water until the filtrate was neutral, and finally dried at 80°C for 8 hours to obtain the product;

[0046] (2) Add 1.5 g of the above product into 25 mL of deionized water, ultrasonically disperse for 30 min, add 8 drops of aqueous sodium hydroxide solution (mass fraction 10%), and stir evenly for 7 days;

[0047] (3) Add 7mL DC5700 (40% methanol solution) and 1.5mL KH550 dropwise to the reaction solution obtained in (2). After white precipitate appears, stop stirring, let stand for 12h, wash with deionized water and centrifuge, repeat Washing and centrifuging at least three times, and then drying at 70°C, the hydrophobic titanium dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com