A kind of intumescent water-based fire-proof and flame-retardant coating for wood materials and preparation method thereof

A technology for fire-retardant and flame-retardant coatings and wood materials, applied in fire-resistant coatings, coatings, etc., can solve problems such as affecting the health and life safety of disaster victims and rescuers, hindering evacuation and rescue operations, etc., and achieves good water resistance, The effect of improving toughness and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

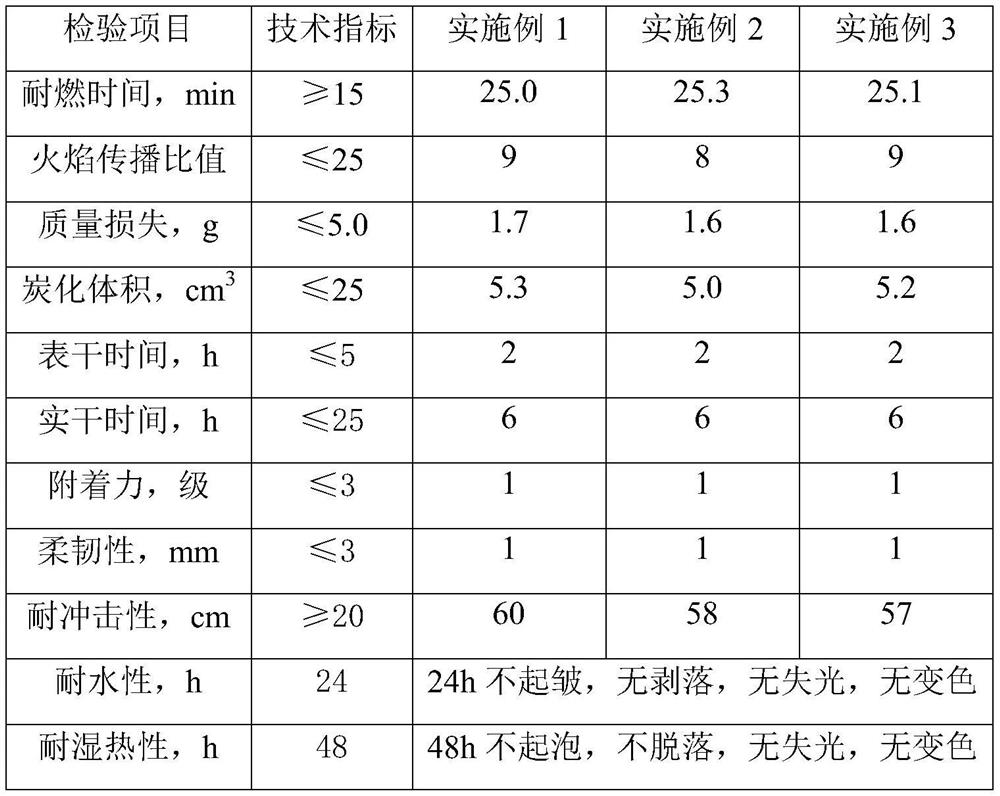

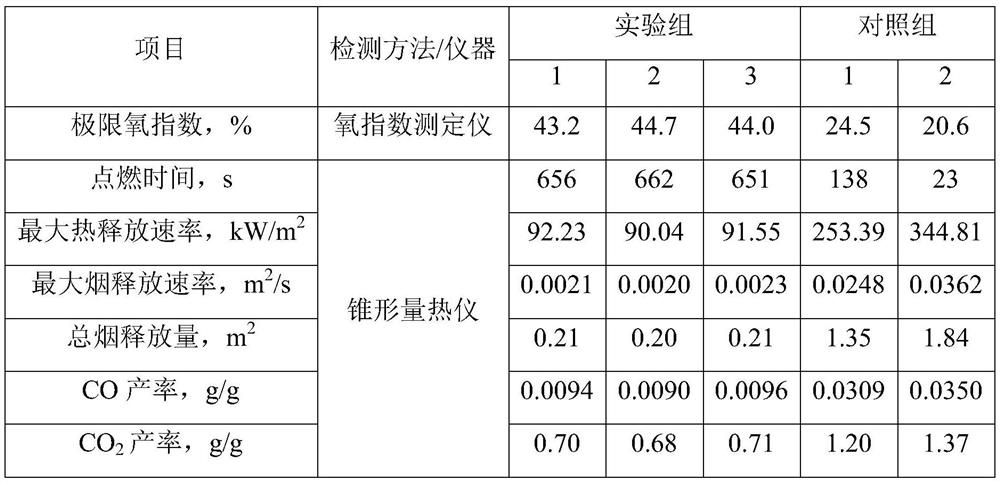

Examples

Embodiment 1

[0039] The intumescent water-based fire-proof and flame-retardant coating for wood materials of the present embodiment consists of water and the following components in parts by weight: 200 parts of melamine-modified urea-formaldehyde resin emulsion, 110 parts of ethylene-vinyl acetate copolymer emulsion, 24 parts of boric acid, 36 parts of amine polyphosphate, 20 parts of guanidine urea phosphate, 36 parts of pentaerythritol, 30 parts of melamine, 1.4 parts of sulfonated carbon, 3.6 parts of zinc borate, 2.4 parts of ammonium octamolybdate, 18 parts of paint additives, 36 parts of pigment and filler titanium dioxide parts; the solid content of the coating is 50%.

[0040] Wherein, the coating aid is composed of film-forming aids, dispersants, defoamers, wetting agents, thickeners and leveling agents, and the film-forming aids and dispersants, defoamers, thickeners , The mass ratio of the leveling agent is 10:1.3:1.2:1.5:2.5:1.5.

[0041] The sulfonated carbon is prepared by ...

Embodiment 2

[0051] The intumescent water-based fire-proof and flame-retardant coating for wood materials of the present embodiment consists of water and the following components in parts by weight: 200 parts of melamine-modified urea-formaldehyde resin emulsion, 115 parts of ethylene-vinyl acetate copolymer emulsion, 22 parts of boric acid, 38 parts of amine polyphosphate, 22 parts of amidine urea phosphate, 38 parts of pentaerythritol, 32 parts of melamine, 1.3 parts of sulfonated carbon, 4.0 parts of zinc borate, 2.0 parts of ammonium octamolybdate, 16 parts of paint additives, 34 parts of titanium dioxide for pigments and fillers parts; the solid content of the coating is 51%.

[0052] Wherein, the coating aid is composed of film-forming aids, dispersants, defoamers, wetting agents, thickeners and leveling agents, and the film-forming aids and dispersants, defoamers, thickeners , The mass ratio of the leveling agent is 10:1.0:1.0:1.0:2.0:1.0.

[0053] The sulfonated carbon is prepared...

Embodiment 3

[0063] The intumescent water-based fire-proof and flame-retardant coating for wood materials of the present embodiment consists of water and the following components in parts by weight: 200 parts of melamine-modified urea-formaldehyde resin emulsion, 120 parts of ethylene-vinyl acetate copolymer emulsion, 20 parts of boric acid, 38 parts of polyphosphate amine, 24 parts of phosphoguanidinyl urea, 40 parts of pentaerythritol, 34 parts of melamine, 1.2 parts of sulfonated carbon, 3.8 parts of zinc borate, 2.2 parts of ammonium octamolybdate, 20 parts of paint additives, 38 parts of pigment and filler titanium dioxide parts; the solid content of the coating is 52%.

[0064] Wherein, the coating aid is composed of film-forming aids, dispersants, defoamers, wetting agents, thickeners and leveling agents, and the film-forming aids and dispersants, defoamers, thickeners , The mass ratio of the leveling agent is 10:1.5:2.0:1.5:3.0:2.0.

[0065] The sulfonated carbon is prepared by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com