Low-viscosity environmental-friendly UV/moisture dual-curing three-proofing adhesive and preparation method thereof

A dual-curing and moisture-curing technology, applied in adhesives, adhesive types, adhesive additives, etc., can solve problems such as high viscosity, achieve good toughness, good surface dryness, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

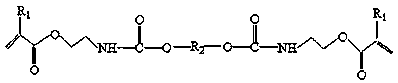

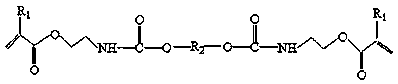

[0027] To make your own low viscosity moisture curable acrylate follow these steps:

[0028] Add 1mol of HDI trimer, 50ppm of polymerization inhibitor, and 100ppm of antioxidant into a three-necked flask with a thermometer, heat and stir, and when the temperature reaches 50°C, add 1mol of hydroxyl acrylate, and continue to heat up to 70-80°C. The reaction is carried out at 70-80°C for 2-3 hours, and the material is discharged after cooling down to obtain a low-viscosity moisture-curable acrylate.

Embodiment 2

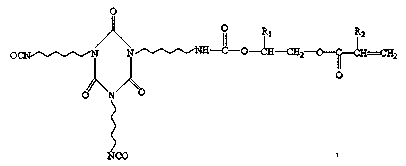

[0030] Self-made viscosity difunctional polyurethane acrylate is carried out according to the following steps:

[0031] Add 2.2mol of isocyanate monomer into a three-necked flask with a thermometer, heat and stir, when the temperature reaches 60°C, add 1mol of polyether diol, add 20ppm of catalyst, raise the temperature to 70-75°C, react for 2~3h, use infrared The spectrometer analyzes the content of OH groups, and when the peak of OH completely disappears, the addition reaction is stopped to obtain low-viscosity difunctional polyurethane acrylate.

Embodiment 3

[0033] The present invention selects self-made low-viscosity moisture-curable acrylate, self-made low-viscosity bifunctional urethane acrylate, acrylic reactive diluent, photoinitiator, polymerization inhibitor, silane coupling agent, according to the appropriate number of formulations , to prepare low-viscosity environmentally friendly UV / moisture dual-cure three-proof adhesive.

[0034] The following are examples given by the inventors, but the present invention is not limited to these examples.

[0035] Table I

[0036]

[0037] Preparation:

[0038]Accurately weigh various raw materials according to the number of formulations in Table 1, self-made low-viscosity moisture-curable acrylate, self-made low-viscosity difunctional urethane acrylate, isobornyl acrylate, tetrahydrofuran acrylate, photoinitiator 184, Photoinitiator TPO, photoinitiator LTM, polymerization inhibitor p-benzoquinone, and coupling agent KH570 are added into the mixer in sequence, the temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com