Extreme pressure anti-wear additive and preparation method thereof

An extreme pressure anti-wear and additive technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor water resistance, achieve good water resistance, solve the effects of easy settlement and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An extreme pressure antiwear additive, comprising the following raw materials in parts by weight:

[0035] Industrial salicylic acid 10 parts, boric acid 80 parts, lithium hydroxide 3 parts, calcium hydroxide 4 parts, potassium hydroxide 40 parts, water 70 parts, base oil A 120 parts, base oil B 60 parts.

[0036] The base oil A is high-viscosity highly refined mineral oil 150BS; the base oil B is a base oil synthesized from esters.

[0037] The extreme pressure antiwear additive and its preparation method specifically comprise the following steps:

[0038] (1) Put base oil A and industrial salicylic acid into the reactor, and stir for 10-20 minutes while heating up;

[0039] (2) When the temperature is raised to 60-80° C., lithium hydroxide, calcium hydroxide and 10% water are prepared into lye and put into the reaction kettle to stir evenly with the mixture of step (1), and slowly heat up for dehydration;

[0040] (3) After the dehydration is completed, when the tem...

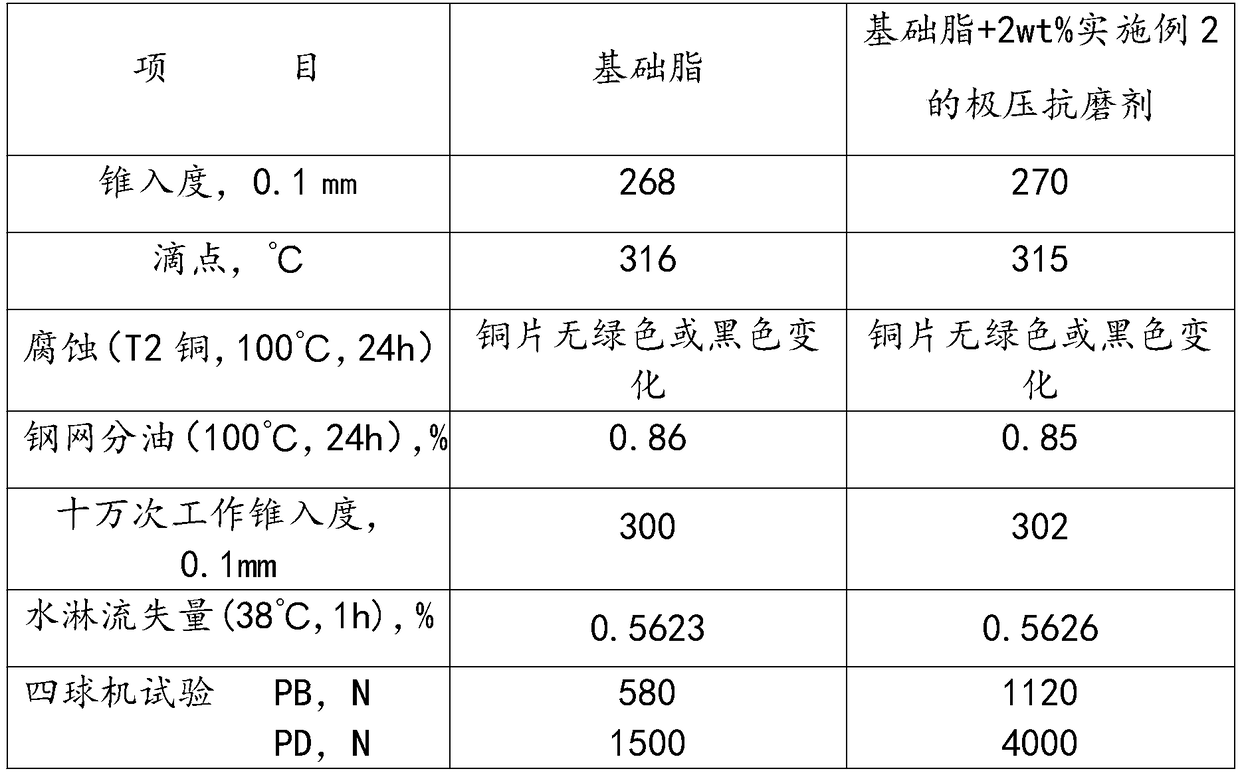

Embodiment 2

[0046] An extreme pressure antiwear additive, comprising the following raw materials in parts by weight:

[0047] 20 parts of industrial salicylic acid, 100 parts of boric acid, 3-4 parts of lithium hydroxide, 4-6 parts of calcium hydroxide, 60 parts of potassium hydroxide, 90 parts of water, 160 parts of base oil A, and 80 parts of base oil B.

[0048] The base oil A is high-viscosity highly refined mineral oil 150BS; the base oil B is a base oil synthesized from esters.

[0049] The extreme pressure antiwear additive and its preparation method specifically comprise the following steps:

[0050] (1) Put base oil A and industrial salicylic acid into the reactor, and stir for 10-20 minutes while heating up;

[0051] (2) When the temperature is raised to 60-80° C., lithium hydroxide, calcium hydroxide and 10% water are prepared into lye and put into the reaction kettle to stir evenly with the mixture of step (1), and slowly heat up for dehydration;

[0052] (3) After the dehydra...

Embodiment 3

[0058] An extreme pressure antiwear additive, comprising the following raw materials in parts by weight:

[0059] Industrial salicylic acid 16 parts, boric acid 90 parts, lithium hydroxide 3.5 parts, calcium hydroxide 5 parts, potassium hydroxide 50 parts, water 80 parts, base oil A 140 parts, base oil B 70 parts.

[0060] The base oil A is high-viscosity highly refined mineral oil 150BS; the base oil B is a base oil synthesized from esters.

[0061] The extreme pressure antiwear additive and its preparation method specifically comprise the following steps:

[0062] (1) Put base oil A and industrial salicylic acid into the reactor, and stir for 10-20 minutes while heating up;

[0063] (2) When the temperature is raised to 60-80° C., lithium hydroxide, calcium hydroxide and 10% water are prepared into lye and put into the reaction kettle to stir evenly with the mixture of step (1), and slowly heat up for dehydration;

[0064] (3) After the dehydration is completed, when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com