Streptomyces aureus fermentation tetracycline production method

A kind of Streptomyces aureus and tetracycline technology, which is applied in the fields of biology and medicine, can solve the problems of the appearance quality of the strain to the influence of the inner spore vitality, the complex composition is difficult to accurately determine, and the appearance quality of the inclined plane fluctuates greatly, etc., and achieves strong adaptability, The effect of improved fermentation level and shorter fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

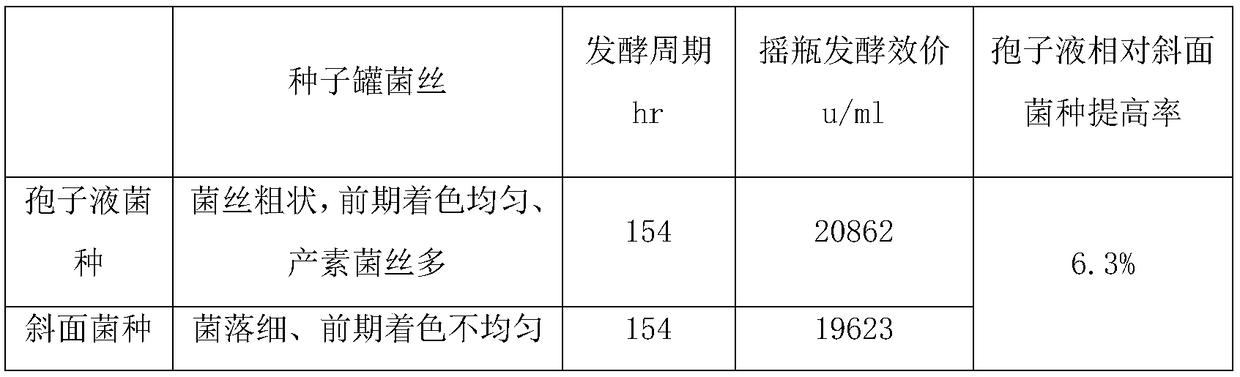

Embodiment 1

[0018] Embodiment 1 (repeat three groups)

[0019] 1. Preparation of spore medium:

[0020] Spore medium formula: bran 1.0%, dipotassium hydrogen phosphate 0.003%, starch 1.0%, magnesium sulfate 0.01%, corn steep liquor 0.3%, yeast powder 0.03%, calcium carbonate 0.01%.

[0021] Preparation method: Dissolve the above materials (except calcium carbonate) and put them in a fixed container, add calcium carbonate to fully dissolve, stir evenly, control the pH at about 7.2, divide into 500ml triangular flasks, each bottle contains 120ml. Carry out sterilization control sterilization temperature 117-121 ℃, pressure 0.08-0.12MPa, sterilization 20-25min, pH after sterilization is 6.4-6.7.

[0022] 2. Spore culture:

[0023] Take 1 tetracycline original strain (Streptomyces aureus), add 1ml of sterile water, shake well, absorb 0.5ml, insert it into the above-mentioned spore culture medium under aseptic conditions, shake well, and culture at 33-35°C for 17 -25 hours.

[0024] 3. Sha...

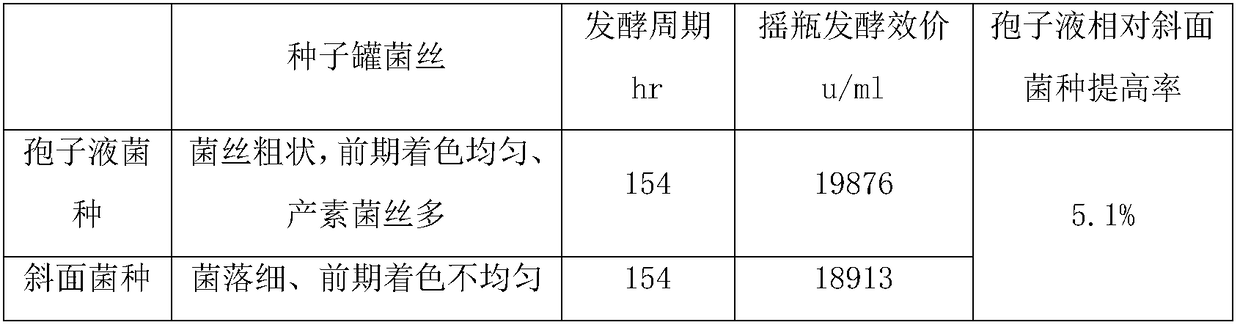

Embodiment 2

[0044] Embodiment 2 (repeat three groups)

[0045] 1. Preparation of spore medium:

[0046] Spore medium formula: bran 1.2%, dipotassium hydrogen phosphate 0.005%, starch 1.2%, magnesium sulfate 0.02%, corn steep liquor 0.5%, yeast powder 0.05%, calcium carbonate 0.02%.

[0047] Preparation method: Dissolve the above materials (except calcium carbonate) and put them in a fixed container, add calcium carbonate to fully dissolve, stir evenly, control the pH at about 7.2, divide into 500ml triangular flasks, each bottle contains 120ml. Carry out sterilization control sterilization temperature 117-121 ℃, pressure 0.08-0.12MPa, sterilization 20-25min, pH after sterilization is 6.4-6.7.

[0048] 2. Spore preparation:

[0049] Take 1 tetracycline original strain (Streptomyces aureus), add 1ml of sterile water, shake well, absorb 0.5ml, insert it into the above-mentioned spore culture medium under aseptic conditions, shake well, and culture at 33-35°C for 17 -25 hours.

[0050] 3....

Embodiment 3

[0070] Embodiment 3 (repeat three groups)

[0071] 1. Preparation of spore medium:

[0072] Spore medium formula: bran 1.5%, dipotassium hydrogen phosphate 0.006%, starch 1.6%, magnesium sulfate 0.03%, corn steep liquor 0.8%, yeast powder 0.06%, calcium carbonate 0.03%.

[0073] Preparation method: Dissolve the above materials (except calcium carbonate) and put them in a fixed container, add calcium carbonate to fully dissolve, stir evenly, control the pH at about 7.2, divide into 500ml triangular flasks, each bottle contains 120ml. Carry out sterilization control sterilization temperature 117-121 ℃, pressure 0.08-0.12MPa, sterilization 20-25min, pH after sterilization is 6.4-6.7.

[0074] 2. Spore culture:

[0075] Take 1 tetracycline original strain (Streptomyces aureus), add 1ml of sterile water, shake well, absorb 0.5ml, insert it into the above-mentioned spore culture medium under aseptic conditions, shake well, and culture at 33-35°C for 17 -25 hours.

[0076] 3. Sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com