Pellet binder with desulfurization function, preparation method and application thereof

A binder and pellet technology, which is applied in the field of pellet binder and its preparation, to achieve the effects of improving desulfurization efficiency, increasing decomposition temperature, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

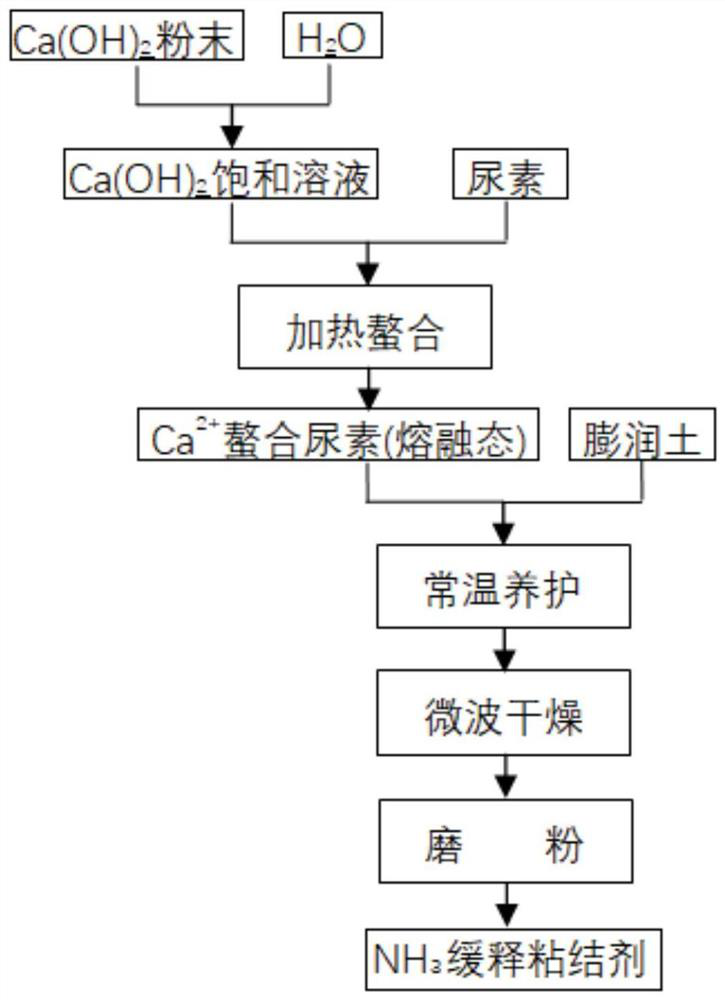

[0037] The pellet binder with desulfurization function of this embodiment includes the following components in terms of mass percentage: 2.5-10wt.% urea, 2.5-10wt.% Ca(OH) 2and 80-95wt.% bentonite, and the pellet binder is in the form of powder, and its particle size content of less than 0.074mm is greater than or equal to 95wt.%. Its preparation method comprises the following steps:

[0038] P1. Digest quicklime with water to form Ca(OH) 2 Saturated solution, add Ca(OH) 2 Equal quality of urea, fully stirred evenly;

[0039] P2. Heat and stir the mixed solution to evaporate the mixed solution until the reactants are in a molten state; specifically, stir and heat the mixed solution at a constant temperature of 100-120° C. for 0.5-3 hours;

[0040] P3. Add bentonite to the above melt and add water, and stir evenly; specifically, the quality of the added bentonite is Ca(OH) 2 and 4-19 times the mass sum of urea, and add 5-8wt.% water by mass percentage, and then stir evenly;...

Embodiment 2

[0053] The pellet binder with desulfurization function in this embodiment is basically the same as the above-mentioned embodiment, the difference is that the pellet binder in this embodiment includes the following components in terms of mass percentage: 5wt.% urea, 5wt. .% Ca(OH) 2 and 90wt.% bentonite, when prepared:

[0054] In step P1: 5 parts by mass of Ca(OH) 2 The saturated lime water that makes mixes with 5 mass parts urea;

[0055] In step P2: Stir and heat the mixed solution at a constant temperature for 1 hour at 120°C;

[0056] In step P3: add 90 parts by mass of bentonite, and add 8 parts by mass of water, and mix vigorously; the quality of bentonite is Ca(OH) 2 and 9 times the mass sum of urea;

[0057] In step P4: place the mixture at room temperature for 12 hours, then place it in a microwave oven with the temperature controlled at 100° C., heat for 1 hour, and then finely grind the agglomerated material to a particle size of less than 0.074 mm and a content...

Embodiment 3

[0060] The pellet binder with desulfurization function of this embodiment is basically the same as the above-mentioned embodiment, the difference is that the pellet binder in this embodiment comprises the following components in terms of mass percentage: 10wt.% urea, 10wt. .% Ca(OH) 2 and 80wt.% bentonite, when prepared:

[0061] In step P1: 10 parts by mass of Ca(OH) 2 The saturated lime water that makes mixes with 10 mass parts urea;

[0062] In step P2: stirring and heating the mixed solution at a constant temperature for 3 hours at 100°C;

[0063] In step P3: add 80 parts by mass of bentonite, and add 5 parts by mass of water, and mix vigorously; the quality of bentonite is Ca(OH) 2 and 4 times the mass sum of urea;

[0064] In step P4: place the mixture at room temperature for 14 hours, then place it in a microwave oven with the temperature controlled at 80° C., heat for 2 hours, and then finely grind the agglomerated material to a particle size of less than 0.074 mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com