Preparation method of manganese oxide supported normal temperature catalyst and application

A manganese oxide, supported technology is applied in the field of preparation of manganese oxide-supported room temperature catalysts, which can solve the problems of difficult application of powder catalysts, and achieves the promotion of catalytic oxidation reaction and intermediate product conversion, mild reaction conditions and complete removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of manganese oxide supported normal temperature catalyst of the present invention, comprises the following steps:

[0022] (1) Carrier pretreatment: add the carrier to water to wash 1 to 8 times, filter and dry at room temperature to 100°C; wherein, the carrier is at least one of ceramics, zeolite, silica gel, fiber, activated carbon, and molecular sieve, and the carrier is The size is not less than 60 mesh.

[0023] (2) Catalyst preparation: Dissolve permanganate in water, add additives, stir and mix evenly, put the cleaned carrier into the mixed solution, stir and react at room temperature for 0.5-12 hours, filter and air-dry naturally or place at 30-120 ℃ oven drying to obtain manganese oxide loaded catalyst at normal temperature; wherein, permanganate is sodium permanganate, ammonium permanganate, potassium permanganate, calcium permanganate, magnesium permanganate, zinc permanganate at least one of . The concentration of permanganate ...

Embodiment 1

[0028] Add activated carbon carrier with a size of not less than 60 mesh into water and wash 6 times, filter and dry in an oven at 30°C; dissolve 0.09mol potassium permanganate in 100mL water, add 0.08mol citric acid additive and stir until mixed evenly, and wash Put 9g of activated carbon into the mixed solution, stir and react at room temperature for 8h, filter and dry in an oven at 105°C to obtain MnO x / activated carbon.

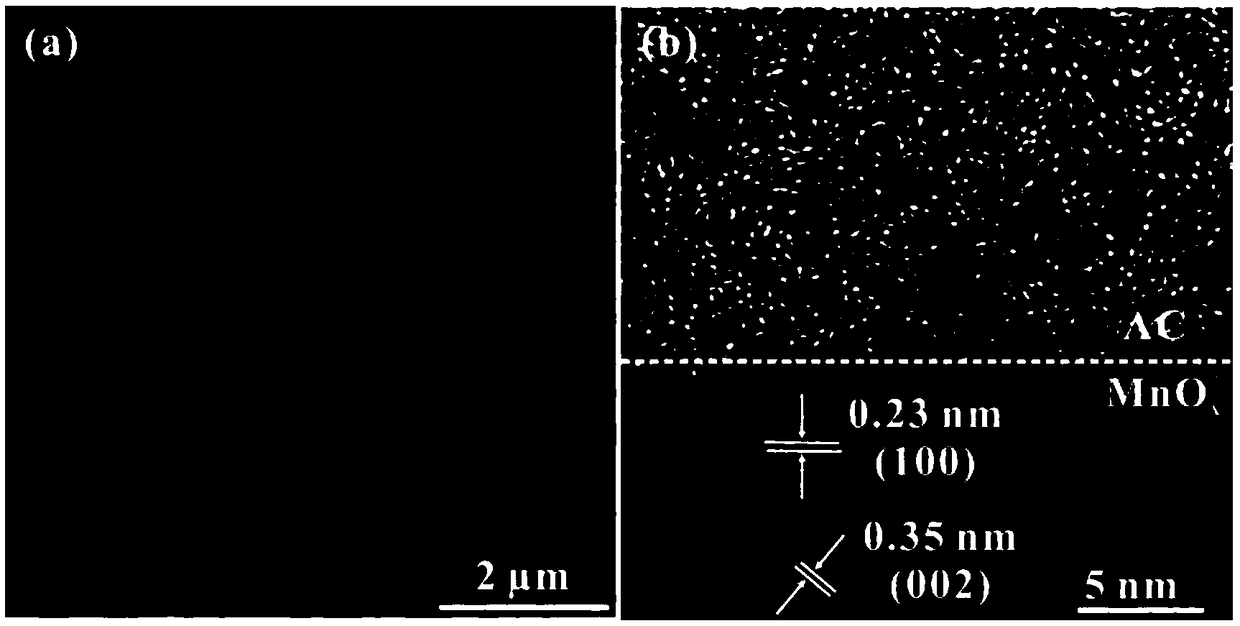

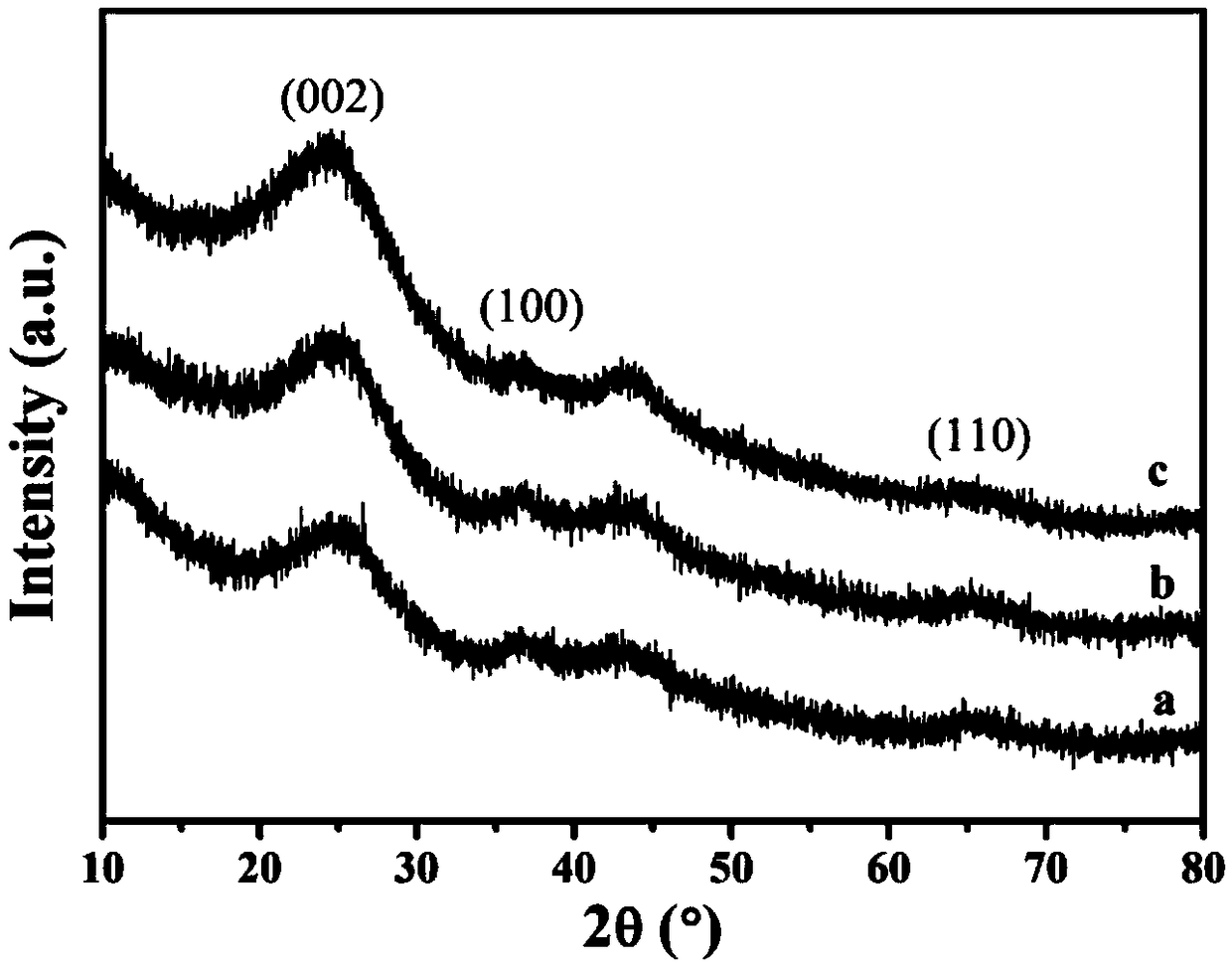

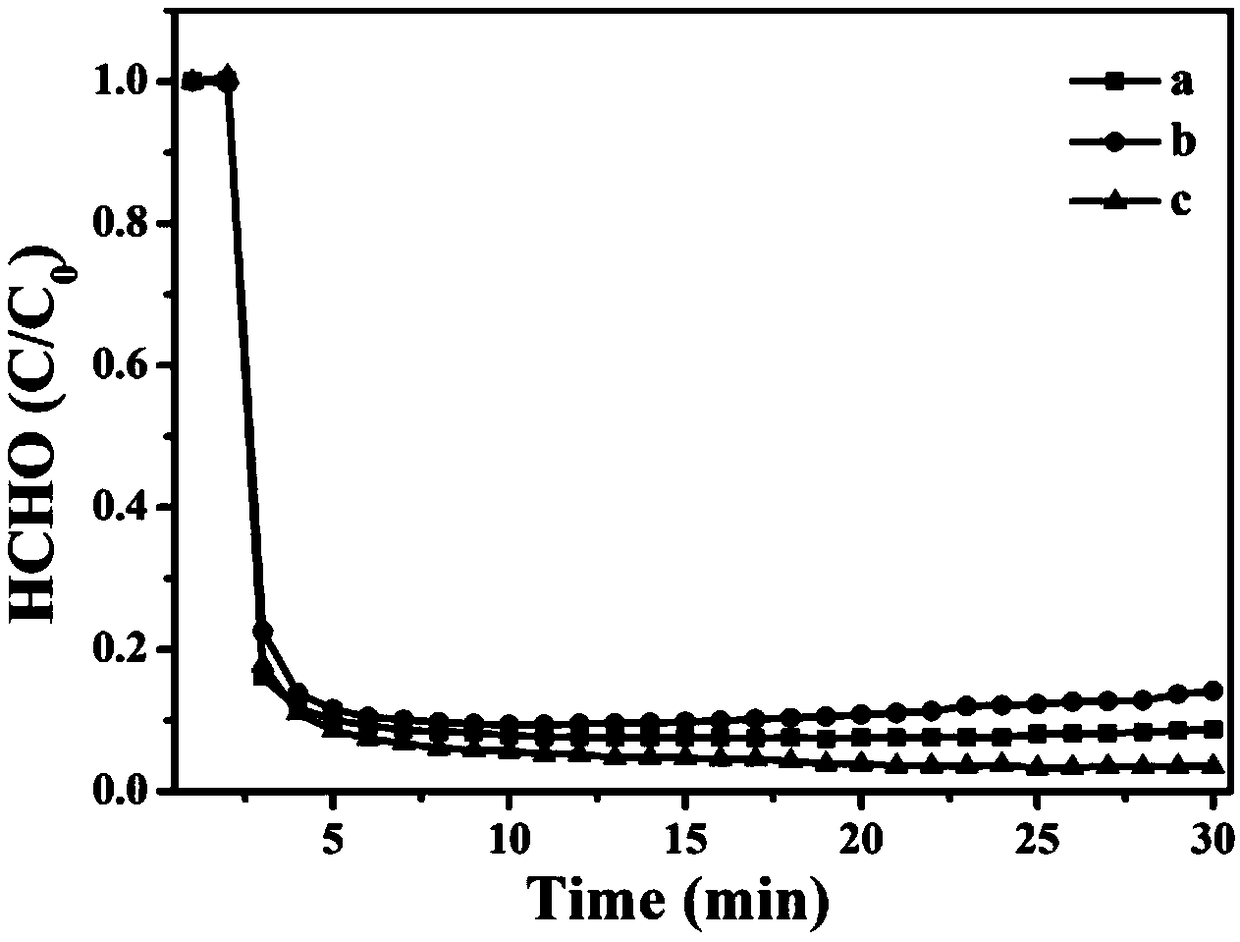

[0029] figure 1 The SEM image in (a) shows that MnO x The particles are uniformly coated on the surface of the activated carbon carrier; figure 1 (b) TEM images of activated carbon and MnO x The interface is clearly visible, indicating that the MnO x Successfully loaded on the surface of activated carbon; figure 2 The XRD in a shows that the surface of activated carbon supports MnO x It is birnessite type with poor crystallinity; image 3 It can be seen from the figure of formaldehyde removal rate in a that MnO x / The removal rate of formaldeh...

Embodiment 2

[0031] Add the molecular sieve carrier with a size of not less than 60 mesh into water to wash twice, filter and dry in an oven at 50°C; dissolve 0.10mol of sodium permanganate in 100mL of water, add 0.05mol of ethylene glycol additives and stir until evenly mixed, and wash The final 6g molecular sieve was put into the mixed solution, stirred and reacted at room temperature for 6h, filtered and air-dried to obtain MnO x / molecular sieve.

[0032] figure 2 The XRD in b shows that the surface of the molecular sieve supports MnO x It is birnessite type with poor crystallinity; image 3 The formaldehyde removal rate figure in b shows that MnO x / Molecular sieves can remove formaldehyde up to 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com