Preparation method and application of a molybdenum and nitrogen doped lignocellulose composite nano-adsorption material

A nano-adsorption material and lignocellulose technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of high operating costs, short service life, and need for regeneration, and achieve low cost, Anti-aging, repeated use rate, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

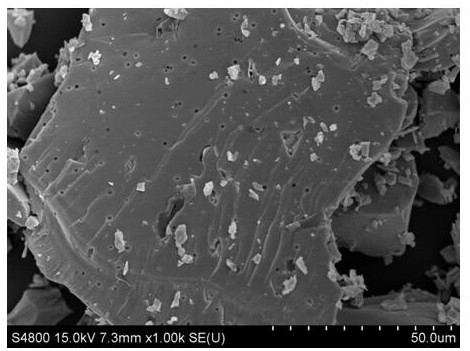

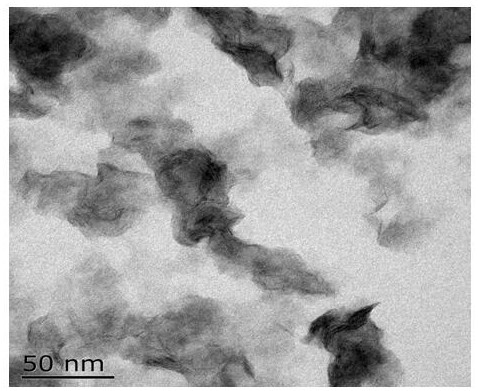

[0056] The preparation and application of a kind of molybdenum, nitrogen-doped lignocellulose composite nano-adsorption material of the present invention, comprises the following steps successively:

[0057] Lignocellulose was calcined at 800°C for 2 hours in an ammonia atmosphere, the heating rate was 5°C / min, and then ground after natural cooling to obtain nitrogen-doped lignocellulose;

[0058] (1) Dissolve 0.5mmol of ammonium molybdate in 40mL of deionized water to form solution I;

[0059] (2) Dissolve 10mmol thioacetamide in 40mL deionized water to make solution II;

[0060] (3) Fully mix solution I and solution II to prepare solution III;

[0061] (4) Add 30 mg of nitrogen-doped lignocellulose into solution III, and stir evenly to obtain solution IV;

[0062] (5) Transfer 80mL of solution IV to a 100mL autoclave and react at 200°C for 20h;

[0063] (6) After the solution is cooled, centrifuge the reaction product of step (6), collect the precipitate, wash with deioni...

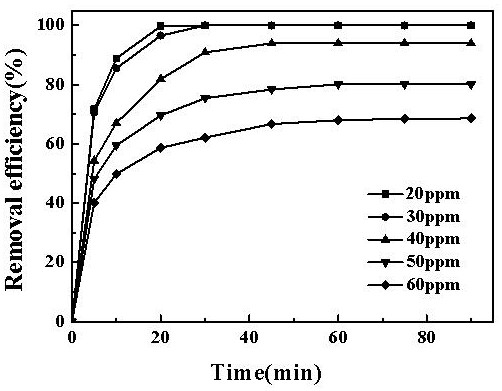

Embodiment 2

[0071] The preparation and application of a kind of molybdenum, nitrogen-doped lignocellulose composite nano-adsorption material of the present invention, comprises the following steps successively:

[0072] (1) Lignocellulose was calcined at 800°C for 2 hours in an ammonia atmosphere, the heating rate was 5°C / min, and then ground after natural cooling to obtain nitrogen-doped lignocellulose;

[0073] (2) Dissolve 0.5mmol of ammonium molybdate in 40mL of deionized water to make solution I;

[0074] (3) Dissolve 10mmol of thioacetamide in 40mL of deionized water to form solution II;

[0075] (4) Fully mix solution I and solution II to prepare solution III;

[0076] (5) Add 30 mg of nitrogen-doped lignocellulose into solution III, and stir evenly to obtain solution IV;

[0077] ⑹Transfer 80mL of solution IV to a 100mL autoclave, and react at 200°C for 20h;

[0078] (7) After the solution is cooled, centrifuge the reaction product of step (6), collect the precipitate, wash it ...

Embodiment 3

[0086] The preparation and application of a kind of molybdenum, nitrogen-doped lignocellulose composite nano-adsorption material of the present invention, comprises the following steps successively:

[0087] (1) Lignocellulose was calcined at 800°C for 2 hours in an ammonia atmosphere, the heating rate was 5°C / min, and then ground after natural cooling to obtain nitrogen-doped lignocellulose;

[0088] (2) Dissolve 0.5mmol of ammonium molybdate in 40mL of deionized water to make solution I;

[0089] (3) Dissolve 10mmol of thioacetamide in 40mL of deionized water to form solution II;

[0090] (4) Fully mix solution I and solution II to prepare solution III;

[0091] (5) Add 30 mg of nitrogen-doped lignocellulose into solution III, and stir evenly to obtain solution IV;

[0092] ⑹Transfer 80mL of solution IV to a 100mL autoclave, and react at 200°C for 20h;

[0093] (7) After the solution is cooled, centrifuge the reaction product of step (6), collect the precipitate, wash it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com