Method for producing long-chain fatty acid and glyceryl triacetate through grease

A technology of glycerol triacetate and long-chain fatty acids, which is applied in chemical instruments and methods, preparation of carboxylate esters, preparation of carboxylate esters/lactones, etc., can solve the problems of unavoidable discharge of small molecule toxic substances and high production costs, Achieve high selectivity and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

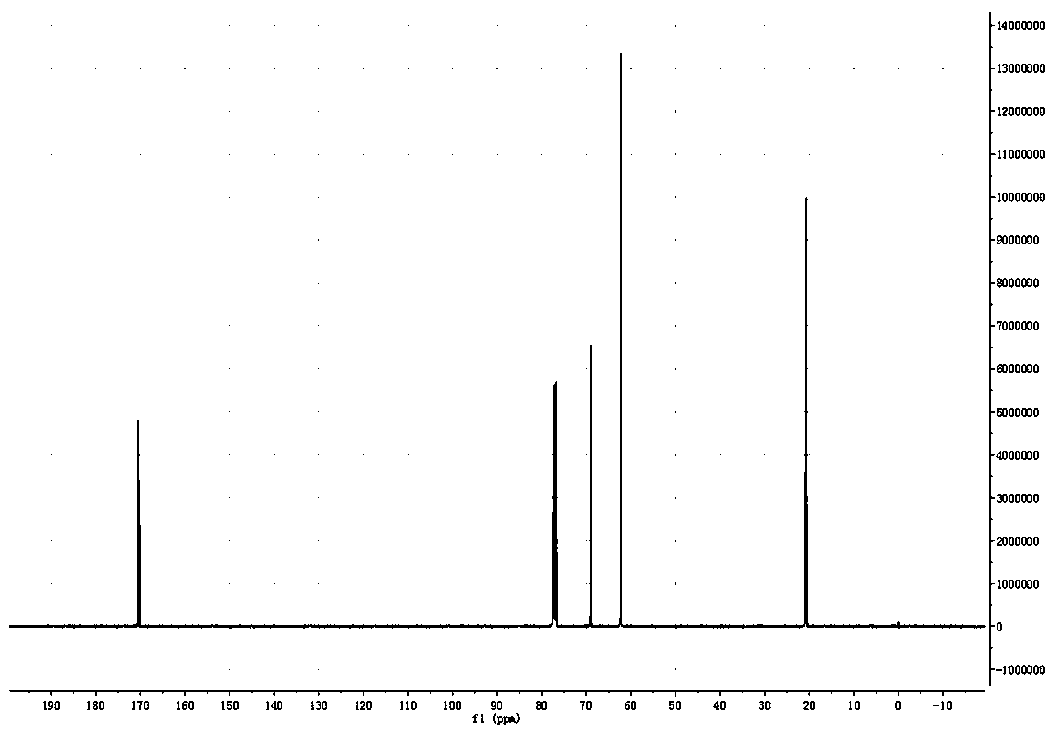

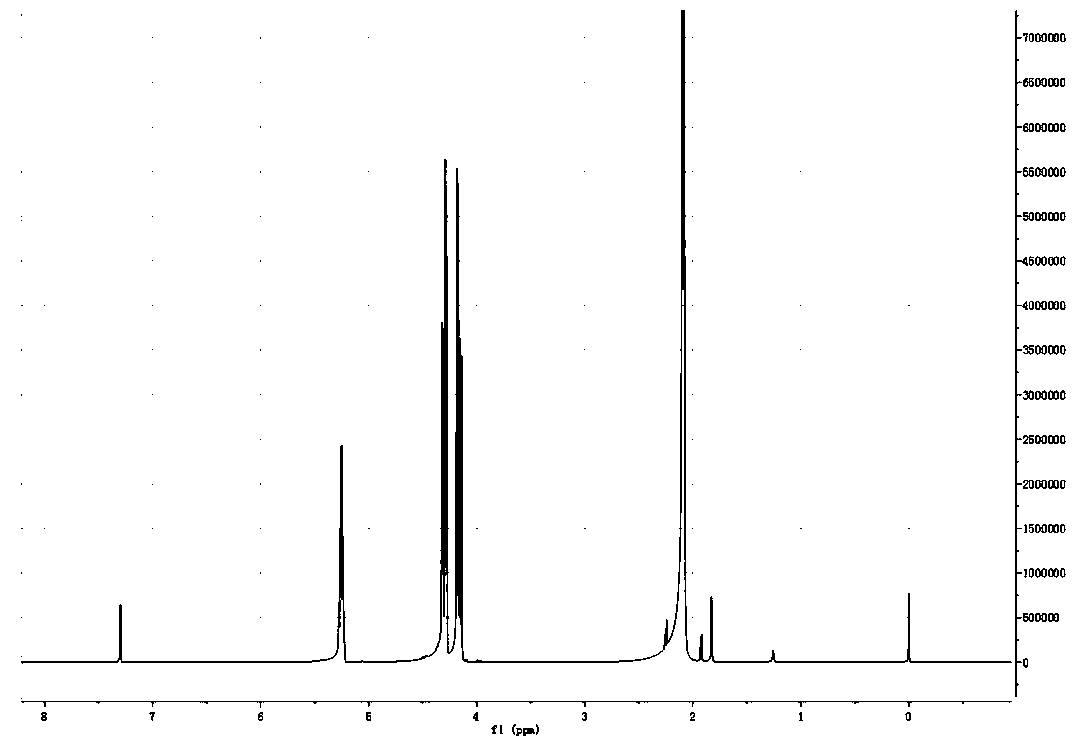

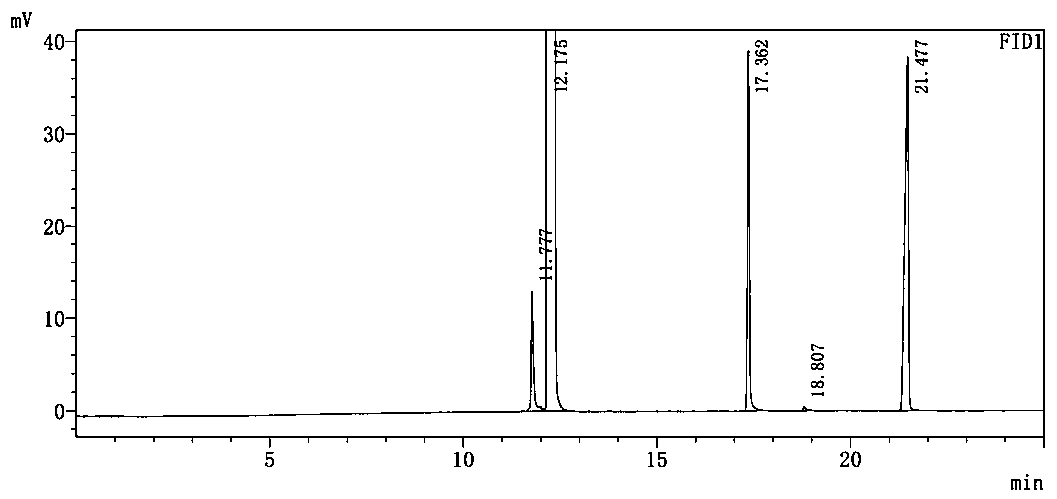

[0036] Mix 1.0g glyceryl tristearate, 0.01g phosphotungstic acid and 0.2g glacial acetic acid, react at 120°C for 10h, filter at 60°C after the reaction is completed, and obtain phosphotungstic acid insoluble in acetic acid, cool the filtrate to 40°C, and filter The long-chain fatty acid solid that separates out, after the filtrate decompression distillation, reclaims acetic acid, and obtains glyceryl triacetate (see attached figure 1 , 2 , 3), the conversion rate of glyceryl tristearate is 100% through analysis, and the molar yield of glyceryl triacetate is 95%, and long-chain fatty acid (see attached Figure 4 and 5 ) are all octadecyl fatty acids, and the yield is 100%.

Embodiment 2

[0038] Mix 1.0g tallow oil, 0.05g benzenesulfonic acid and 100g mass percent concentration of 80% acetic acid aqueous solution, react at 140°C for 8h, after the reaction is completed, filter the precipitated long-chain fatty acid solid, and then distill the filtrate under reduced pressure, Reclaim acetic acid, add 0.01g organic solvent ethyl ether and leave standstill layering, obtain organic solution and the catalyzer after reaction, distill and remove organic solvent, obtain glyceryl triacetate, the conversion ratio of oil and fat is 100% through analysis, the glycerol triacetate The molar yield is 97%, and the long-chain fatty acids are all octadecyl fatty acids, and the yield is 98%.

Embodiment 3

[0040] Mix 1.0g of lard oil, 0.1g of p-toluenesulfonic acid and 80g of 90% acetic acid aqueous solution by mass, and react at 160°C for 4 hours. After the reaction is completed, filter the precipitated fatty acid solid, and then distill the filtrate under reduced pressure to recover Acetic acid, add 0.05g organic solvent chloroform and leave standstill layering, obtain organic solution and the catalyzer after reaction, distill and remove organic solvent, obtain glyceryl triacetate, the conversion rate of oil and fat is 100% through analysis, the mole of glyceryl triacetate The yield is 96%, and the long-chain fatty acids are all octadecyl fatty acids, and the yield is 96%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap