Corrosion-resistant halogen-free flame-retardant unsaturated polyester resin and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of corrosion-resistant, halogen-free flame-retardant unsaturated polyester resin and its preparation, can solve the problem of reducing the anti-ultraviolet ability of the flame-retardant base material, unfavorable large-scale production and use of products, and flame-retardant The price of resin raw materials is relatively expensive, etc., to achieve the effect of improving hardness, easy molding, and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

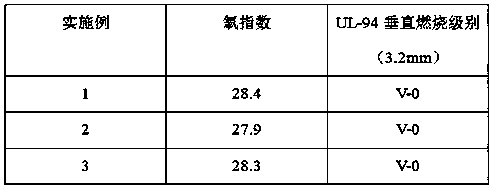

Examples

Embodiment 1

[0031] A corrosion-resistant, halogen-free, flame-retardant unsaturated polyester resin, comprising the following components in parts by weight: 50 parts of unsaturated polyester resin, 0.5 parts of initiator, 10 parts of filler, 30 parts of diluent, and 5 parts of flame retardant , 5 parts of anti-corrosion additives.

[0032] Further, the unsaturated polyester resin is phthalic acid type.

[0033] Further, the initiator is methyl ethyl ketone peroxide.

[0034] Further, the filler is modified alumina ceramic powder, and the preparation method of the modified alumina ceramic powder includes the following steps:

[0035] 1) Put 0.3 parts of alumina ceramic powder into a hydrochloric acid solution with a mass fraction of 8%, heat it in a water bath to 40°C, stir for 1 hour, filter it, wash it to neutrality, and dry it by microwave at a drying temperature of 100°C , to obtain activated alumina ceramic powder;

[0036] 2) Grinding the dried crab shells into powder to obtain cr...

Embodiment 2

[0050] A corrosion-resistant, halogen-free, flame-retardant unsaturated polyester resin, comprising the following components in parts by weight: 70 parts of unsaturated polyester resin, 1 part of initiator, 20 parts of filler, 40 parts of diluent, and 10 parts of flame retardant , 7 parts of anti-corrosion additives.

[0051] Further, the unsaturated polyester resin is isophthalic acid type.

[0052] Further, the initiator is cyclohexanone peroxide.

[0053] Further, the filler is modified alumina ceramic powder, and the preparation method of the modified alumina ceramic powder includes the following steps:

[0054] 1) Put 0.4 parts of alumina ceramic powder into a hydrochloric acid solution with a mass fraction of 9%, heat it in a water bath to 50°C, stir for 2 hours, filter it, wash it to neutrality, and dry it by microwave at a drying temperature of 110°C , to obtain activated alumina ceramic powder;

[0055] 2) Grinding the dried crab shells into powder to obtain crab s...

Embodiment 3

[0070] A corrosion-resistant, halogen-free, flame-retardant unsaturated polyester resin, comprising the following components in parts by weight: 90 parts of unsaturated polyester resin, 2 parts of initiator, 30 parts of filler, 50 parts of diluent, and 20 parts of flame retardant , 8 parts of anti-corrosion additives.

[0071] Further, the unsaturated polyester resin is bisphenol A type unsaturated polyester resin.

[0072] Further, the initiator is tert-butyl peroxybenzoate.

[0073] Further, the filler is modified alumina ceramic powder, and the preparation method of the modified alumina ceramic powder includes the following steps:

[0074] 1) Put 0.5 parts of alumina ceramic powder into a hydrochloric acid solution with a mass fraction of 10%, heat it in a water bath to 60°C, stir for 2 hours, filter, wash until neutral, and dry it by microwave at a drying temperature of 120°C , to obtain activated alumina ceramic powder;

[0075] 2) Grinding the dried crab shells into p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com