Halogen-free flame-retarding unsaturated polyester resin glass-reinforced plastic and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of halogen-free flame retardant unsaturated polyester resin glass fiber reinforced plastic and its preparation, to achieve the effects of improving wear resistance, reducing water absorption and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

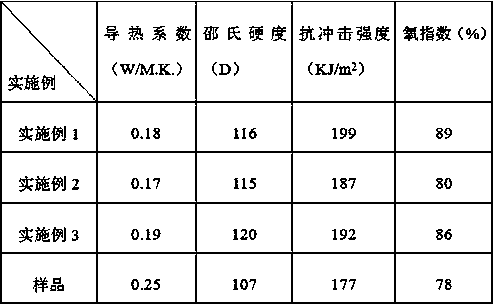

Examples

Embodiment 1

[0033] A halogen-free flame-retardant unsaturated polyester resin glass fiber reinforced plastics, comprising the following components in parts by weight: 50 parts of o-phthalic unsaturated polyester resin, 0.5 parts of methyl ethyl ketone peroxide, 5 parts of zinc stearate, 10 parts of carbon fiber, 25 parts of alkali-free glass fiber with a length of 3 mm, 30 parts of styrene, and 5 parts of aluminum hydroxide.

[0034] Described alkali-free glass fiber is through pretreatment, and the specific steps of pretreatment are:

[0035] 1) Calcining the alkali-free glass fiber in a muffle furnace, the calcination temperature is 400°C, and the calcination time is 1h, and the calcined glass fiber is obtained for use;

[0036] 2) Put the alkali-free glass fiber calcined in step 1) into soapy water for ultrasonic cleaning for 5 minutes, then ultrasonically clean it with clean water for 3 minutes, and then dry it to obtain the alkali-free glass fiber after drying and removing impurities...

Embodiment 2

[0049]A halogen-free flame-retardant unsaturated polyester resin glass fiber reinforced plastics, comprising the following components in parts by weight: 70 parts of isophthalic unsaturated polyester resin, 1 part of cyclohexanone peroxide, 7 parts of calcium stearate, carbon nano 20 parts of tubes, 35 parts of alkali-free glass fibers with a length of 3 mm, 40 parts of methyl methacrylate, and 15 parts of modified aluminum hydroxide. When carbon nanotubes are used, the specific steps of processing are: Soak in ethanol for 2~3h, then reflux the carbon nanotubes with 1:1 nitric acid for 12h~24h. Remove the residual nitric acid by filtration to obtain a precipitate. After the precipitate is ultrasonically treated with mixed acid (the volume ratio of concentrated nitric acid and concentrated sulfuric acid is 1:3) for 2~4 hours, it is then ultrasonically treated with 20% hydrogen peroxide aqueous solution for 2~4 hours. Centrifuge and wash with double distilled water until neutral...

Embodiment 3

[0064] A halogen-free flame-retardant unsaturated polyester resin glass fiber reinforced plastics, comprising the following components in parts by weight: 90 parts of vinyl-type unsaturated polyester resin, 1.5 parts of methyl ethyl ketone peroxide, 10 parts of magnesium stearate, and 30 parts of graphene , 50 parts of alkali-free glass fiber with a length of 3 mm, 50 parts of styrene, and 20 parts of modified aluminum hydroxide.

[0065] The alkali-free glass fiber with a length of 3mm is pretreated, and the specific steps of pretreatment are as follows:

[0066] 1) Calcining the alkali-free glass fiber in a muffle furnace, the calcination temperature is 450°C, and the calcination time is 1h, and the calcined glass fiber is obtained for use;

[0067] 2) Put the alkali-free glass fiber calcined in step 1) into soapy water for 10 minutes of ultrasonic cleaning, then ultrasonically clean it with clean water for 5 minutes and then dry it to obtain the alkali-free glass fiber afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com