Method for producing glycine

一种制造方法、甘氨酸的技术,应用在有机化学方法、化学仪器和方法、有机化合物的制备等方向,能够解决工序数变多等问题,达到收率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

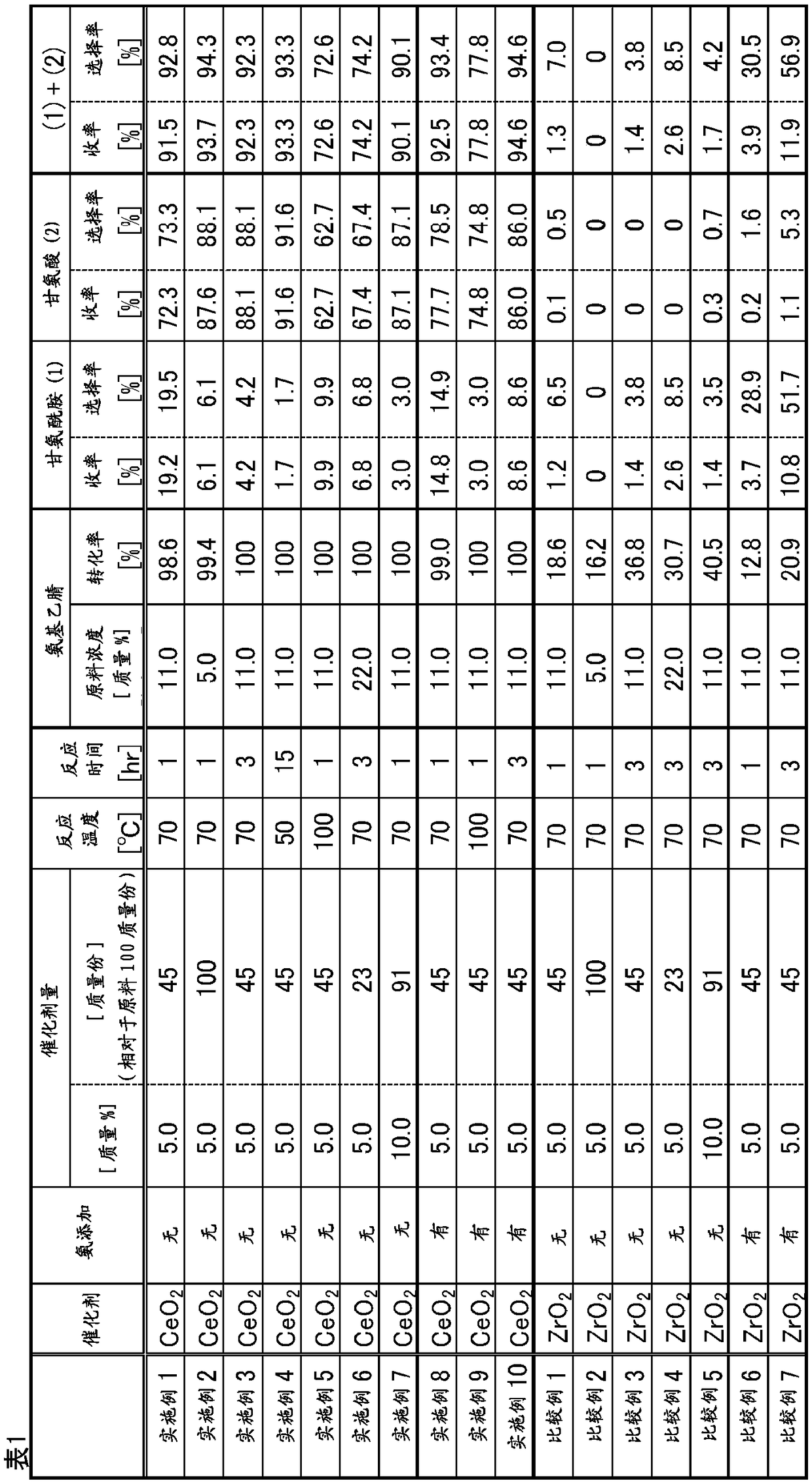

[0097] In a 15 mL glass pressure vessel with a stirrer bar added, CeO 2 0.5 g (concentration in liquid: 5.0 mass % with respect to aminoacetonitrile aqueous solution; 45 mass parts with respect to 100 mass parts of aminoacetonitrile (raw material)). 10.0 g of an aminoacetonitrile aqueous solution having a concentration of 11.0% by mass was added thereto. Furthermore, the pressure vessel was sealed, and it stirred at 70 degreeC for 1 hour. The pressure vessel was cooled to room temperature (25° C.), and the reaction liquid in the vessel was analyzed by HPLC.

Embodiment 2~7

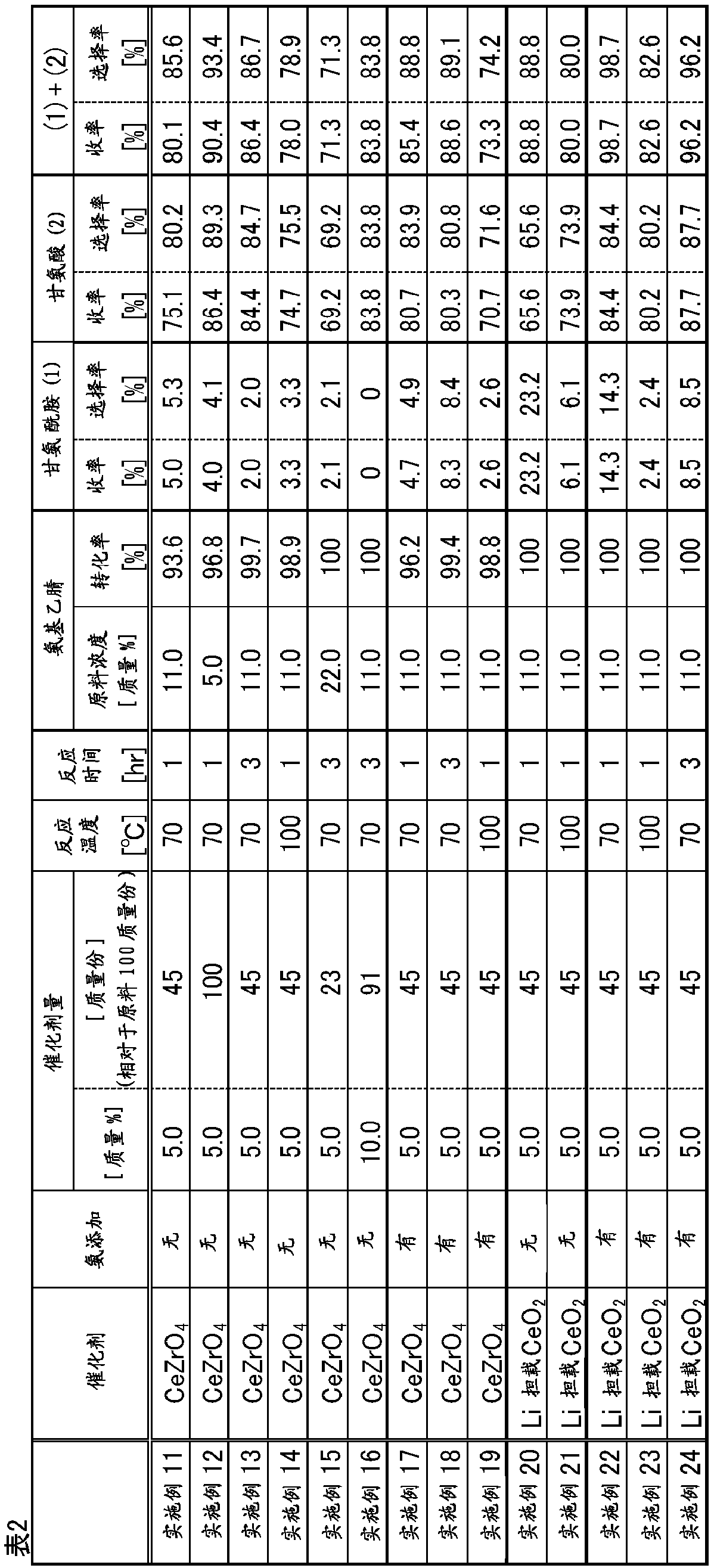

[0099]Except having changed the reaction conditions in Example 1 to the conditions shown in following Table 1, it carried out similarly to Example 1, and reacted, and HPLC analysis of the reaction liquid was performed.

Embodiment 8

[0101] In a 15 mL glass pressure vessel with a stirrer bar added, CeO 2 0.5 g (concentration in liquid: 5.0 mass % with respect to aminoacetonitrile aqueous solution; 45 mass parts with respect to 100 mass parts of aminoacetonitrile (raw material)). To this, 28% of ammonia aqueous solution was added so that the liquid concentration of ammonia might become 10.0 mass %, and it prepared. Next, 10.0 g of an aqueous aminoacetonitrile solution having a concentration of 11.0% by mass was added. Furthermore, the pressure vessel was sealed, and it stirred at 70 degreeC for 1 hour. The pressure vessel was cooled to room temperature (25° C.), and the reaction liquid in the vessel was analyzed by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com