Conductive paste and method for forming conductive pattern

A conductivity and patterning technology, which is applied in the formation of conductive patterns, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as difficult to print with thin lines, poor transfer of substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

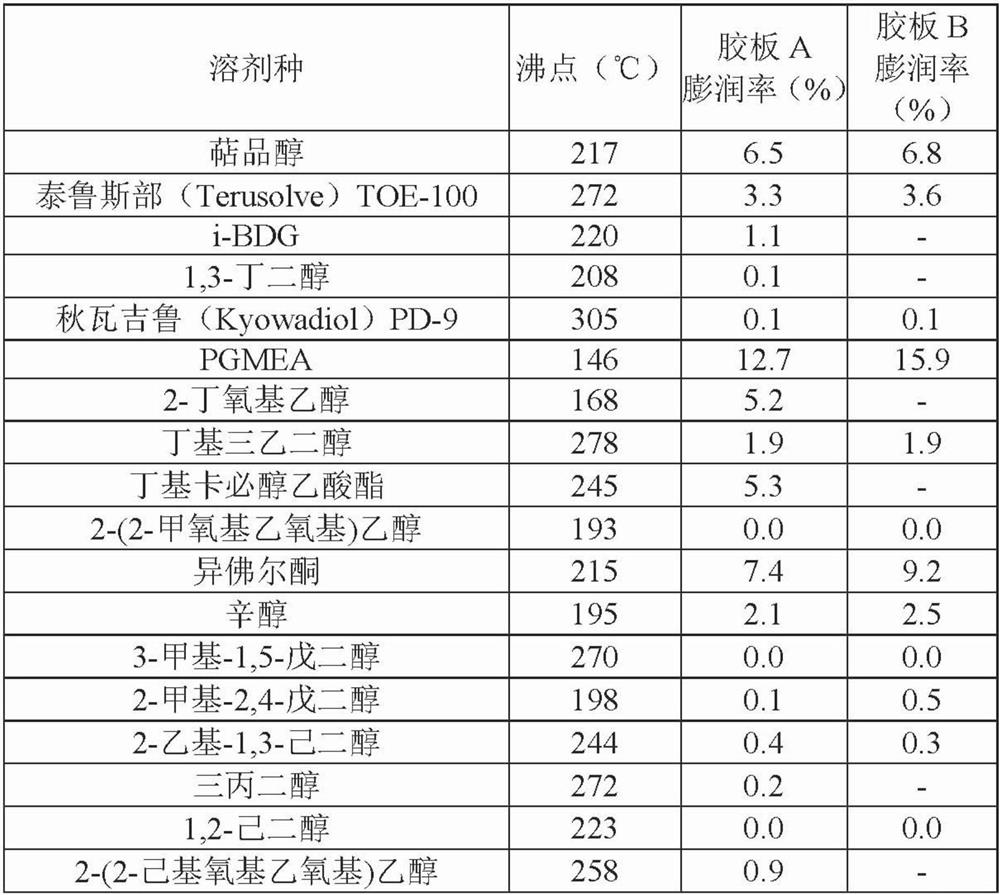

Method used

Image

Examples

Embodiment 1

[0124] 9.0 g of 3-methoxypropylamine (a primary reagent manufactured by Wako Pure Chemical Industries, Ltd.), and 0.2 g of DISPERBYK-102 (DISPERBYK)-102 as a polymer dispersant Chemicals (manufactured by BYK Chemie)) were mixed and fully stirred with a magnetic stirrer to generate an amine mixed liquid. Then, while stirring, 3.0 g of silver oxalate was added. After the silver oxalate was added, stirring was continued at room temperature to change the silver oxalate into a viscous white substance, and the stirring was terminated when it was confirmed that the change was complete in appearance.

[0125] The obtained mixed solution was transferred to an oil bath, and heated and stirred at 120°C. Immediately after the start of stirring, the reaction accompanied by the generation of carbon dioxide was started, and then the stirring was continued until the generation of carbon dioxide was completed, thereby obtaining a suspension in which silver microparticles were suspended in the...

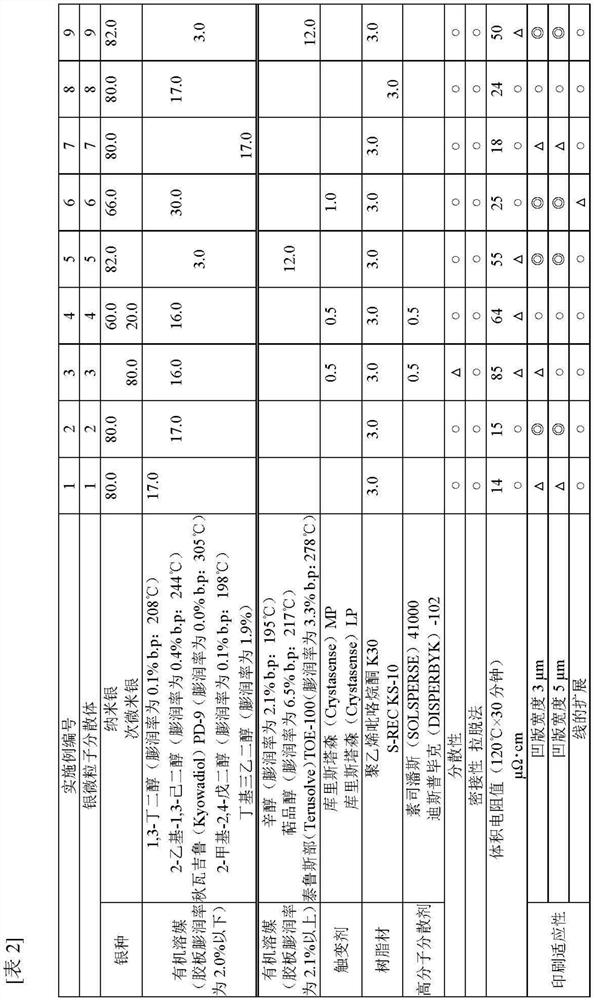

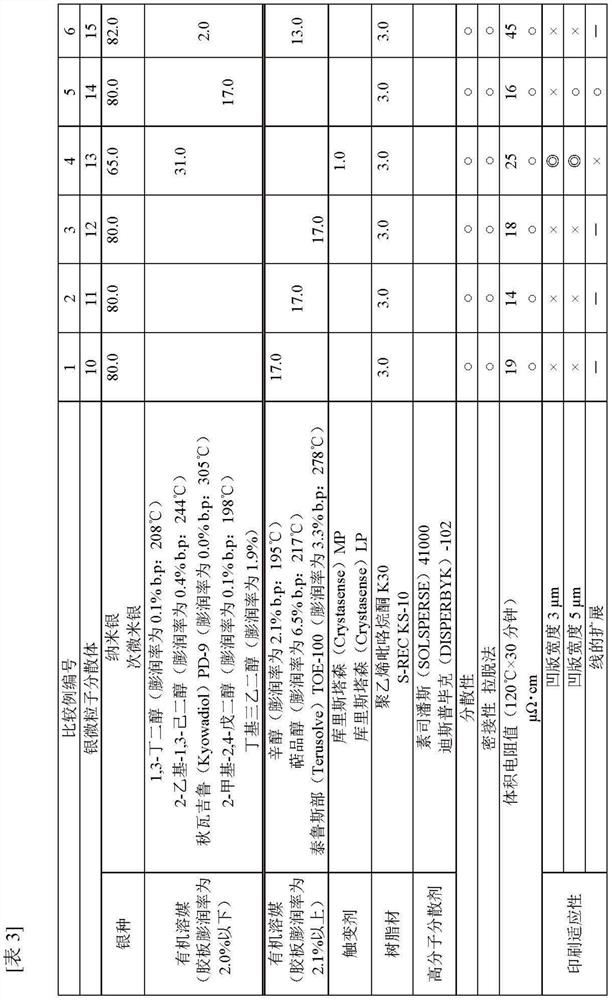

Embodiment 2

[0143] For 80 parts by weight of silver nanoparticle slurry obtained in the same manner as in Example 1, the organic solvent added was changed to 17 parts by weight from 1,3-butanediol (a first-class reagent manufactured by Wako Pure Chemical Industry Co., Ltd.). An implementation conductive paste 2 was obtained in the same manner as in Example 1 except that 2 ethyl-1,3-hexanediol isomer mixture (first-class reagent manufactured by Wako Pure Chemical Industries, Ltd.) was used. Moreover, the evaluation of implementing the electrically conductive paste 2 was performed similarly to Example 1, and the obtained result is shown in Table 2.

Embodiment 3

[0145] Add 3 parts by weight of S-REC KS-10 (manufactured by Sekisui Chemical Co., Ltd.) ), 0.5 parts by weight of Kulistasen (Crystasense) MP (manufactured by Kuo De (CLODA) company) as a thixotropic agent, 0.5 parts by weight of Susperse (SOLSPERSE) 41000 (SOLSPERSE) 41000 (Japan) as a polymer dispersant Lubrizol (manufactured by Japan Lubrizol)) dissolved in 16 parts by weight of 2 ethyl-1,3-hexanediol isomer mixture (a primary reagent manufactured by Wako Pure Chemical Industries, Ltd.) Except having added 20 weight part of solutions in total, it carried out similarly to Example 1, and obtained the implementation conductive paste 3. Moreover, the evaluation of implementing the electrically conductive paste 3 was performed similarly to Example 1, and the obtained result is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com