Processing technology of highland barley instant powder

A highland barley instant powder and processing technology, which is applied in the field of food processing, can solve the problems of reducing the health care and medicinal value of highland barley, destroying the nutritional components of highland barley, and being difficult for human body to digest and absorb, so as to facilitate the absorption and utilization of human body and keep it from being lost , The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

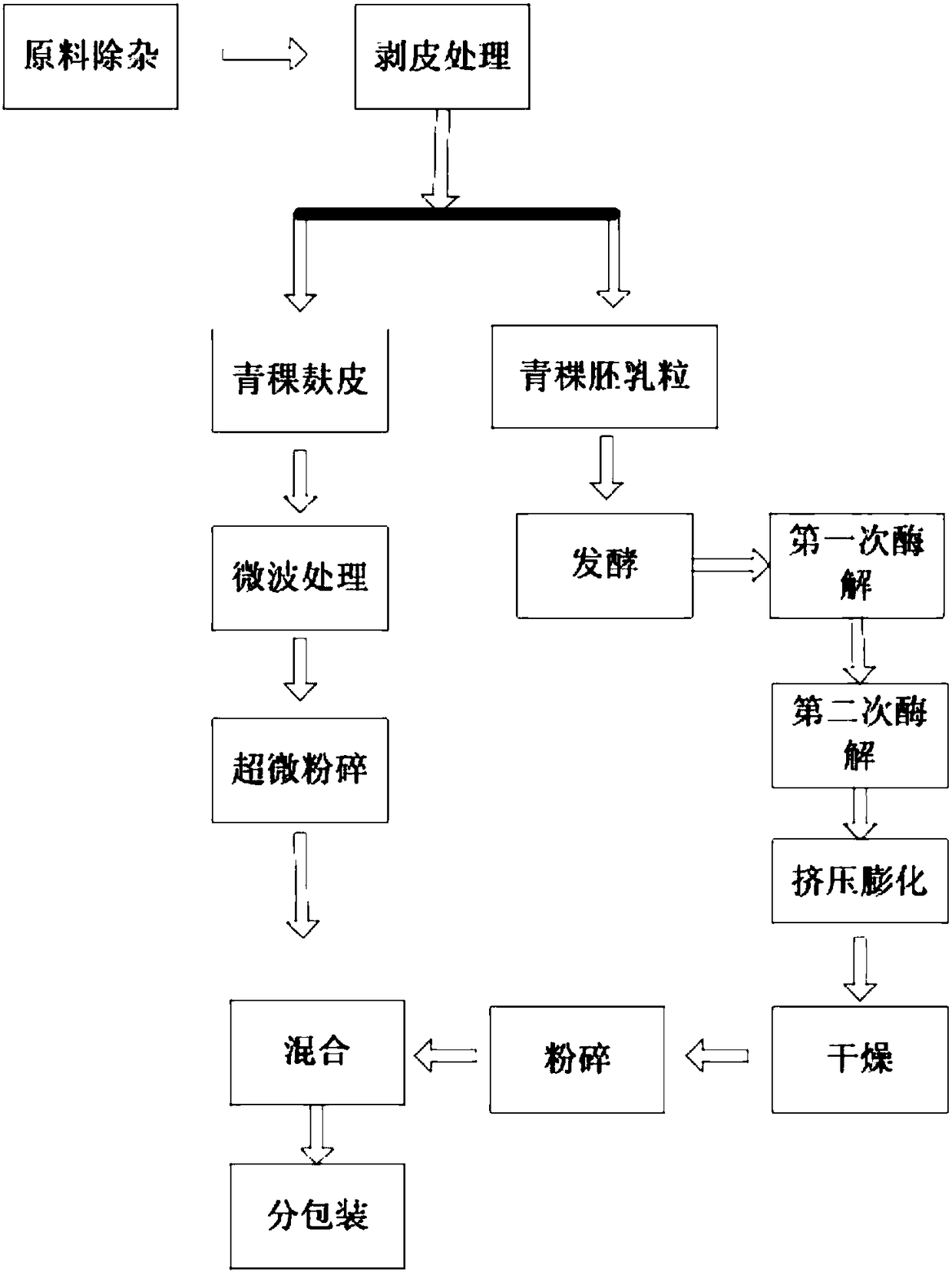

Image

Examples

Embodiment 1

[0054] Step 1. Raw material removal

[0055] Select dry, mildew-free, and high-quality highland barley without peculiar smell, and remove weeds, shells, sand, stones, and metal impurities in the raw materials to obtain clean raw materials.

[0056] Step 2, Peeling

[0057] Add the raw material prepared in step 1, for example, to warm water at 35° C., the amount of water added is, for example, 15% of the weight of the raw material, stir evenly, and then let stand for 12 hours to moisten the wheat. The raw materials after tempering are put into, for example, an FBPY type wheat peeling machine for peeling to obtain highland barley bran and highland barley endosperm grains.

[0058] Step 3, microwave-processing the highland barley bran prepared in step 2. The parameters of the microwave treatment process are power 350W, time 3min, and cooling to below 40°C.

[0059] Step 4. Fermentation of highland barley endosperm grains

[0060] The highland barley endosperm grains prepared ...

Embodiment 2

[0071] Step 1. Raw material removal

[0072] Select dry, mildew-free, and high-quality highland barley without peculiar smell, and remove weeds, shells, sand, stones, and metal impurities in the raw materials to obtain clean raw materials.

[0073] Step 2, Peeling

[0074] Add the raw material prepared in step 1, for example, to warm water at 30° C., the amount of water added is, for example, 20% of the weight of the raw material, stir evenly, and then let stand for 12 hours to moisten the wheat. The raw materials after tempering are put into, for example, an FBPY type wheat peeling machine for peeling to obtain highland barley bran and highland barley endosperm grains.

[0075] Step 3, microwave-processing the highland barley bran prepared in step 2. The parameters of the microwave treatment process are power 350W, time 4min, and cooling to below 40°C. Microwave treatment can reduce the loss of nutrients in the highland barley bran and improve its taste at the same time. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap