Method for preparing higher hydrocarbons by low-temperature conversion of methane

A low-temperature conversion, high-level hydrocarbon technology, applied in chemical instruments and methods, treatment of hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of catalyst preparation and difficult to achieve reaction conditions, catalyst carbon deposition deactivation and other problems, achieve long life, Good product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

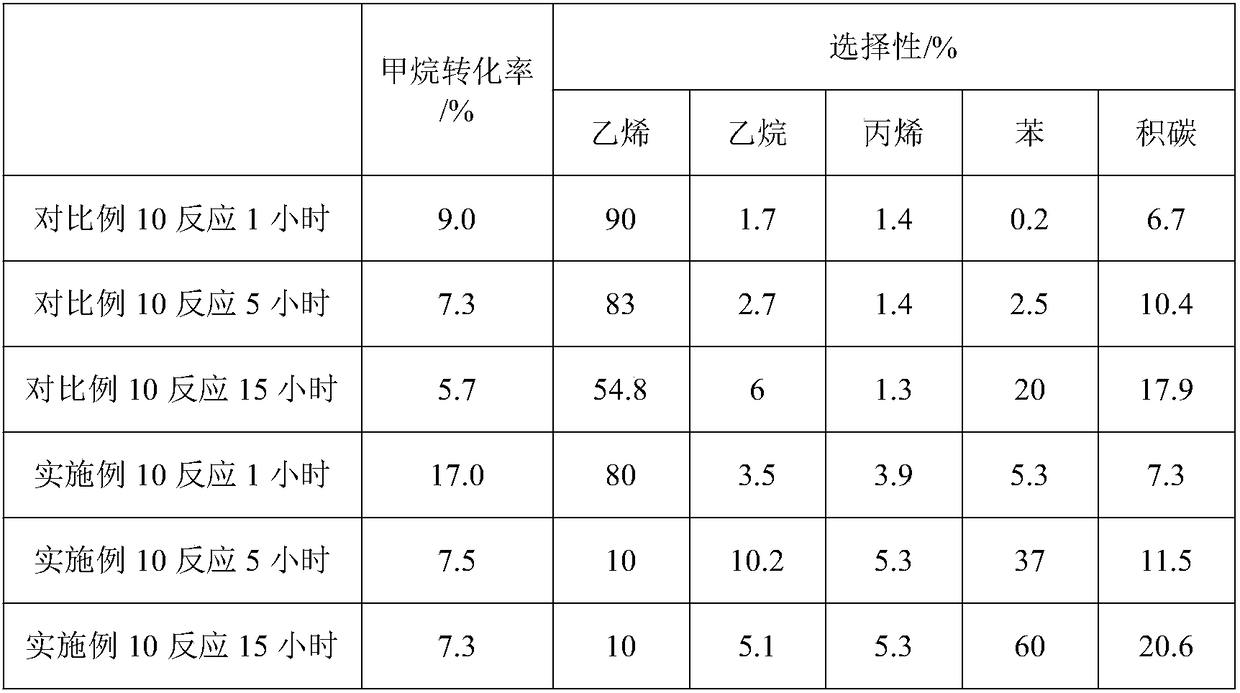

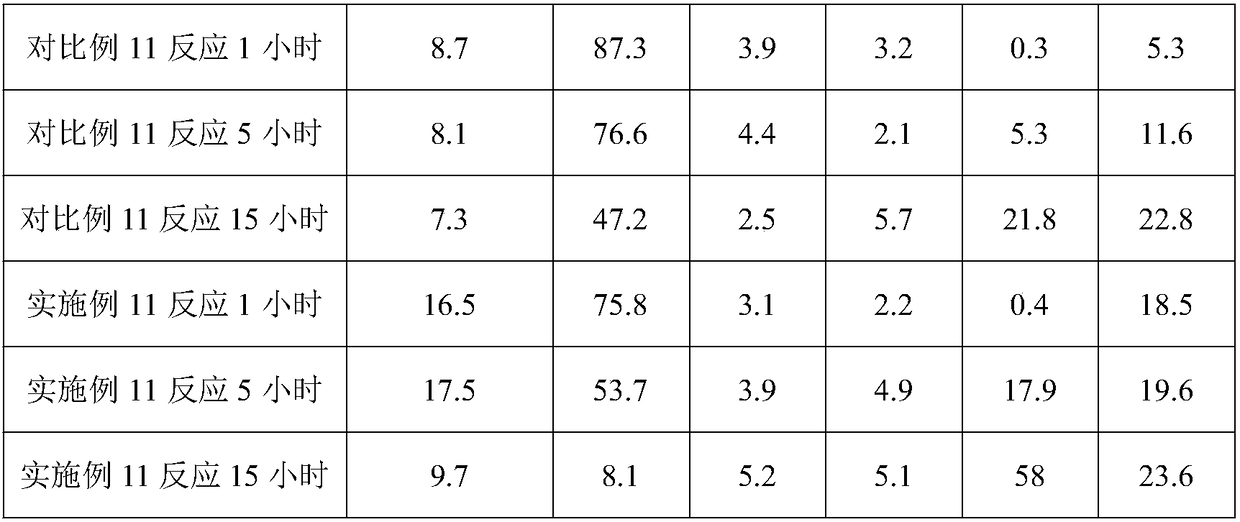

Examples

Embodiment 1

[0029] The carrier of catalyst among the present invention can adopt commercially available product, also can prepare according to following method:

[0030] Take 25.074g template agent tetrapropylammonium hydroxide (abbreviation: TPAOH), add it to 48.400g water, stir magnetically at room temperature, then add 0.938g aluminum nitrate, stir until completely dissolved, then add 20.833g ethyl orthosilicate (abbreviation: TEOS) and stirring continuously, after stirring for 20 hours, let it stand for 4 hours to obtain the synthetic solution; slowly introduce the synthetic solution into a stainless steel autoclave with a polytetrafluoroethylene liner, and seal it; then, place the stainless steel autoclave in Take it out after crystallization in an oven at 120°C for 120 hours, and rapidly cool to room temperature; the obtained product is repeatedly washed with deionized water until the pH value is 9-10, centrifuged, and the solid product is separated, and the obtained solid product is...

Embodiment 2

[0032] The carrier of catalyst among the present invention can adopt commercially available product, also can prepare according to following method:

[0033]Take 25.074g of template agent TPAOH, add it to 48.400g of water, stir magnetically at room temperature, then add 0.750g of aluminum nitrate, stir until completely dissolved, then add 20.833g of TEOS and keep stirring, after stirring for 20h, let it stand for 4h to obtain the synthetic The synthetic solution was slowly introduced into a stainless steel autoclave lined with polytetrafluoroethylene, and sealed; then, the stainless steel autoclave was placed in an oven at 120°C for crystallization for 120 hours, then taken out, and rapidly cooled to room temperature; the obtained product was used Rinse with ionized water repeatedly until the pH value is 9-10, centrifuge to separate the solid product, place the obtained solid product in an oven at 100°C, then heat up to 500°C in a muffle furnace at 2°C / min, and roast for 2 hour...

Embodiment 3

[0035] The carrier of catalyst among the present invention can adopt commercially available product, also can prepare according to following method:

[0036] Take 25.074g of template agent TPAOH, add it to 48.400g of water, stir magnetically at room temperature, then add 0.469g of aluminum nitrate, stir until it is completely dissolved, then add 20.833g of TEOS to the solution and keep stirring, after stirring for 20h, add ethylene glycol 90.79ml of alcohol was stirred for 30min and left to stand for 4h to obtain a synthetic solution, which was slowly introduced into a stainless steel autoclave with polytetrafluoroethylene and sealed; then, the stainless steel autoclave was placed in an oven at 120°C for 120h of crystallization Take it out and cool it down to room temperature; the obtained product is repeatedly washed with deionized water until the pH value is 9-10, centrifuged, and the solid product is separated, and the obtained solid product is placed in an oven at 100 ° C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com