A strain producing L-tryptophan and use thereof

A technology of tryptophan and bacteria, applied in the field of microbial engineering, can solve the problems of long synthesis pathway, low fermentation yield, complex regulation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

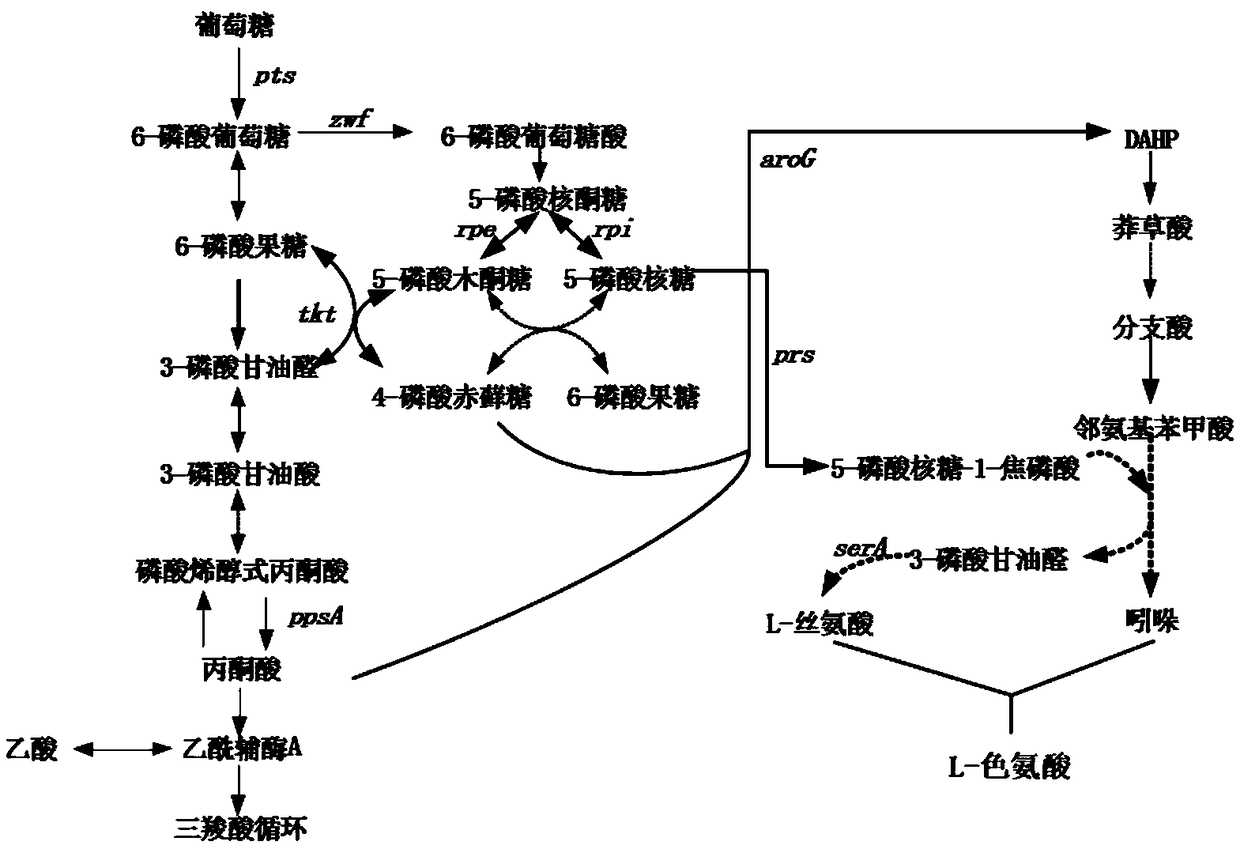

Method used

Image

Examples

Embodiment 1

[0153] The construction of embodiment 1 bacterial strain

[0154] The names and genotype characteristics of the strains constructed in the embodiments of the present invention are shown in Table 4.

[0155] Table 4

[0156]

[0157]According to the method described in patent application WO198701130A1 and Mascarenhas et al. (Mascarenhas D, Ashworth DJ, Chen CS, Deletion of pgi alters tryptophan biosynthesis in genetically engineered strain of Escherichia coli., Appl Environ Microbiol, 1991, 57(10): 2995-2999) The strain TS102 was constructed, that is, the genes tnaA, serA and trpR on the genome of the W3110 wild-type strain were knocked out. The initial strain used was Escherichia coli wild-type W3110 (US5,939,295A). The plasmid used is p5LRPS2, which is described in US5,939,295A, is derived from pBR322, and contains serA, aroG fbr and TrpE fbr DCBA gene fragment.

[0158] 1. Construction of TS05 strain

[0159] Using the TS102 strain as the starting strain, the ptsG s...

Embodiment 2

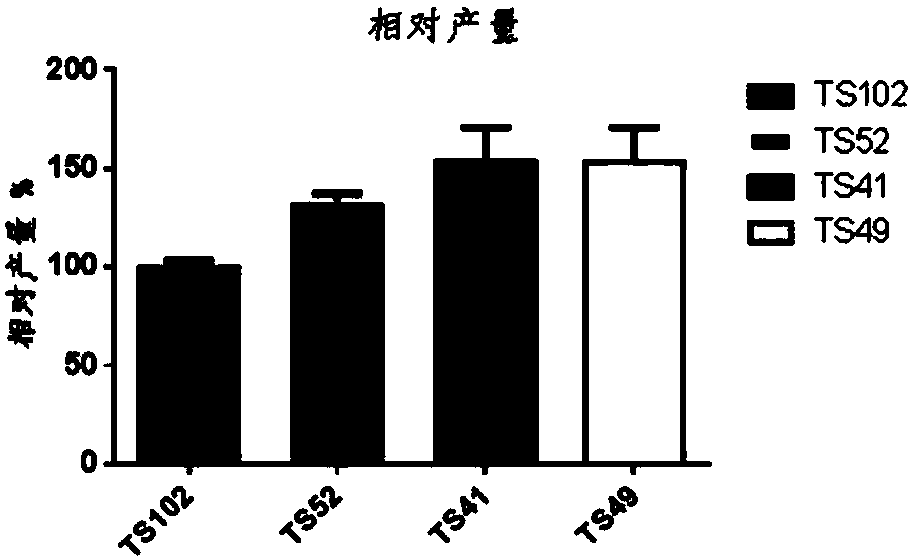

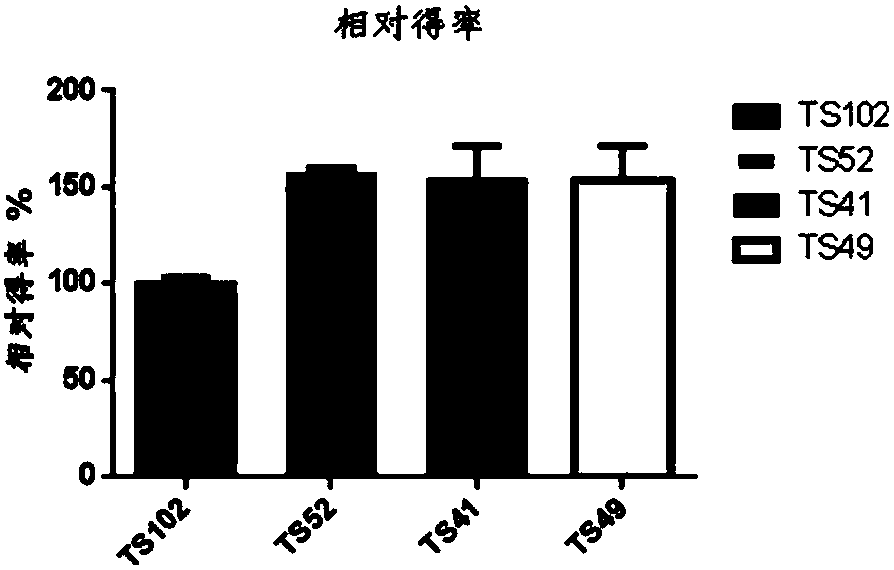

[0203] Example 2 Determination of Efficiency of Fermentative Production of L-Tryptophan by TS102, TS52, TS41 and TS49 Strains

[0204] Pick each strain from the solid plate, place it in a test tube containing 4mL LB liquid medium, and culture it at 35°C and 220rpm for 8-14h; transfer the strain to a medium containing 20mL seed medium according to the inoculum size of 1:500 to 1:1000 In a baffled Erlenmeyer flask, culture at 35°C, 220rpm for 10-12h; transfer the strain to a fermentation shaker flask containing 500mL of shaker flask fermentation medium, so that the initial OD600 is 0.6-0.8, at 35°C, 220rpm Cultivate for 12h.

[0205] The content of L-tryptophan in the culture medium was determined by Eclipse XDB-C18 reversed-phase chromatographic column. Mobile phase A component: 20mM sodium acetate + 0.2v / v% triethylamine, 85%; B component: methanol, 15v / v%; flow rate 0.6mL / min; detector: UV detector 280nm absorption peak. The yield of L-tryptophan is measured by the concentr...

Embodiment 3

[0210] Example 3 Determination of TS102, TS401 and TS412 Strain Fermentative Production L-Tryptophan Efficiency

[0211] According to the same method as in Example 2, using TS102 as a control strain, the efficiency of fermentative production of L-tryptophan by TS401 and TS412 strains was determined. The result is shown in Figure 3. Compared with TS102, the yield of TS401 strain increased by 6%, and the yield of TS412 strain increased by 23% relative to TS102. The control strain TS102 detected 1.74g / L tryptophan, and the conversion rate was 8.44%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com